Special peed change mechanism for numerical control machine tool

A technology of speed change mechanism and numerical control machine tool, which is applied to metal processing mechanical parts, drive devices, metal processing equipment, etc., can solve the problems of inconvenient work, low speed change efficiency and long shift time of numerical control machine tools, so as to achieve economical manufacturing cost, The effect of compact structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

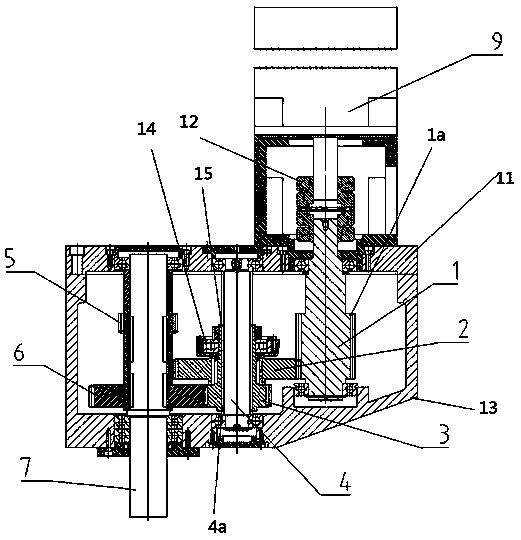

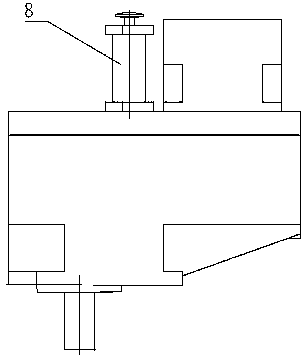

[0018] The present invention comprises driving device 9, shift device 8 and speed change device 11, as figure 1 , figure 2 As shown, the structure of the speed change device 11 is as follows: including a housing 13, a drive shaft 1, a shift shaft 4 and a driven shaft 7;

[0019] The housing 13 is a rectangular cavity with a hypotenuse in the lower right corner;

[0020] The specific positional relationship between the driving shaft 1, the shift shaft 4 and the driven shaft 7 and the housing 13 is as follows: the two ends of the shoulders of the driving shaft 1, the shift shaft 4 and the driven shaft 7 pass through the bearings respectively according to the drive shaft 1, The shifting shaft 4 and the driven shaft 7 are arranged in sequence from right to left in the Y-axis direction inside the cavity of the housing 13, and the shoulders of the driving shaft 1 and the shifting shaft 4 protrude from the upper surface of the housing 13 , the shoulder of the driven shaft 7 protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com