A method for promoting directional crystallization of smelted magnesium oxide

A technology of directional crystallization and magnesia is applied in the field of segmented smelting furnace body and magnesite smelting fused magnesia, which can solve the problems of unreasonable smelting method and unfavorable magnesia crystal formation, and reduce mechanical strength and engineering. Cost, scientific method, and the effect of enhanced cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

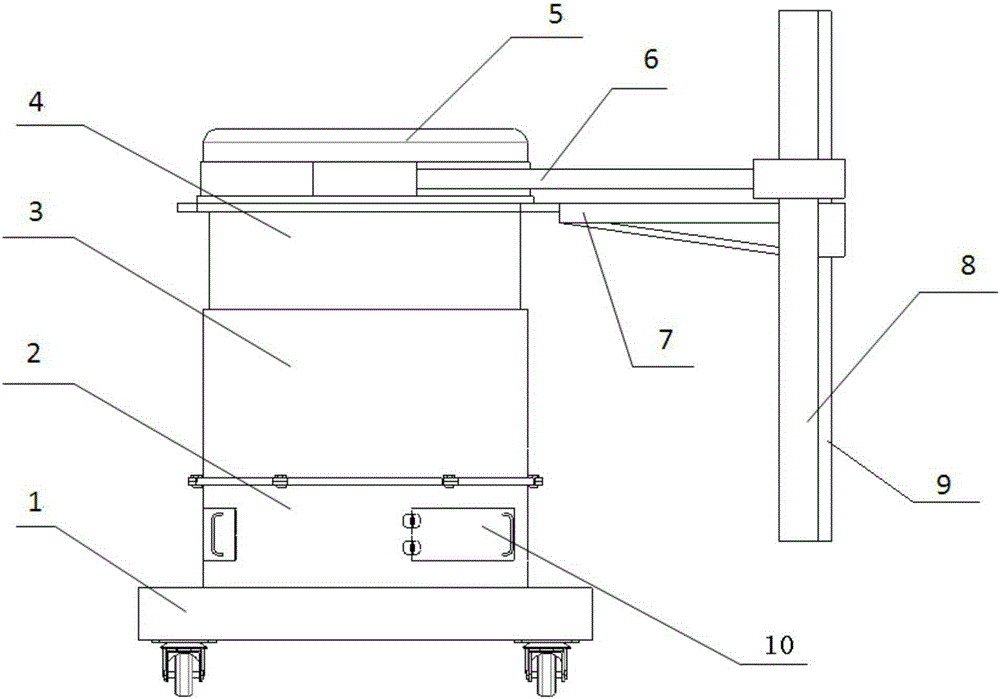

[0036] The sectional melting furnace body of the magnesite smelting electric fused magnesite that present embodiment adopts, as figure 1 As shown, the segmented smelting furnace body includes: bottom material section furnace body 2, smelting section furnace body 3, auxiliary material section furnace body 4, furnace cover 5, auxiliary material section furnace body lifting device and furnace cover lifting device; bottom material section furnace body The body 2, the furnace body 3 of the smelting section and the furnace body 4 of the auxiliary material section are coaxially arranged.

[0037]The base material section furnace body 2 is arranged at the lowermost end of the segmented smelting furnace body, and is used for laying the base material, which is conducive to continuous production. In this embodiment, the bottom material section furnace body 2 is a cylindrical furnace body with an open end, specifically a double-layer furnace body provided with a cooling interlayer. Coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com