A recycled corundum self-flowing castable and its construction method

A construction method and castable technology are applied in the field of refractory materials, which can solve the problems of high production cost and self-flowing castables to be improved, and achieve the effects of simple construction, reduced production cost and enhanced flow performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

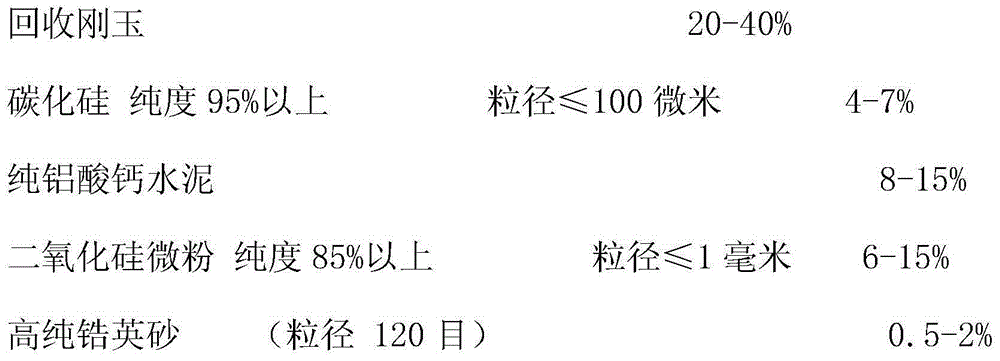

[0025] The present invention provides a recycled corundum self-flowing castable, which includes the following components by weight percentage:

[0026]

[0027] During construction, 0.12% dispersant and 5% water of the total mass of the above corundum self-flowing castable should be added;

[0028] The dispersant is German P530 dispersant;

[0029] During construction, the mold needs to be supported, and the self-flowing castable mixed with water and dispersant is injected into the mold. The self-flowing castable can flow through any surface and fill any space, and quickly bond with the original leftover material without vibration. No noise, while reducing the labor intensity of workers.

Embodiment 2

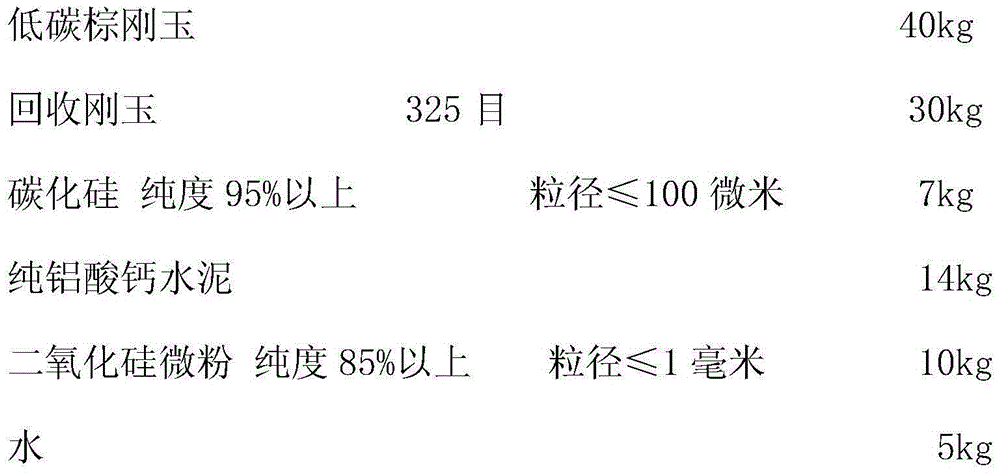

[0031] The present invention provides a recycled corundum self-flowing castable, which includes the following components by weight percentage:

[0032]

[0033] It is necessary to add 0.05% dispersant and 5.5% water of the total mass of the above corundum self-flowing castable during construction;

[0034] During construction, the mold needs to be supported, and the self-flowing castable mixed with water and dispersant is injected into the mold. The self-flowing castable can flow through any surface and fill any space, and quickly bond with the original leftover material without vibration. No noise, while reducing the labor intensity of workers.

[0035] The dispersant is German P530 dispersant;

Embodiment 3

[0037] The present invention provides a recycled corundum self-flowing castable, which includes the following components by weight percentage:

[0038]

[0039]

[0040] During construction, it is necessary to add 0.2% dispersant and 6% water of the total mass of the above corundum self-flowing castable;

[0041] During construction, the mold needs to be supported, and the self-flowing castable mixed with water and dispersant is injected into the mold. The self-flowing castable can flow through any surface and fill any space, and quickly bond with the original leftover material without vibration. No noise, while reducing the labor intensity of workers.

[0042] The dispersant is a mixture of German P530 dispersant and sodium tripolyphosphate, wherein the weight percentage of German P530 dispersant and sodium tripolyphosphate is 3:2;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com