Vapor resistant silicone rubber and preparation method thereof

A water vapor, silicone rubber-resistant technology, applied in the field of silicone rubber, can solve problems such as the deterioration of silicone performance, and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

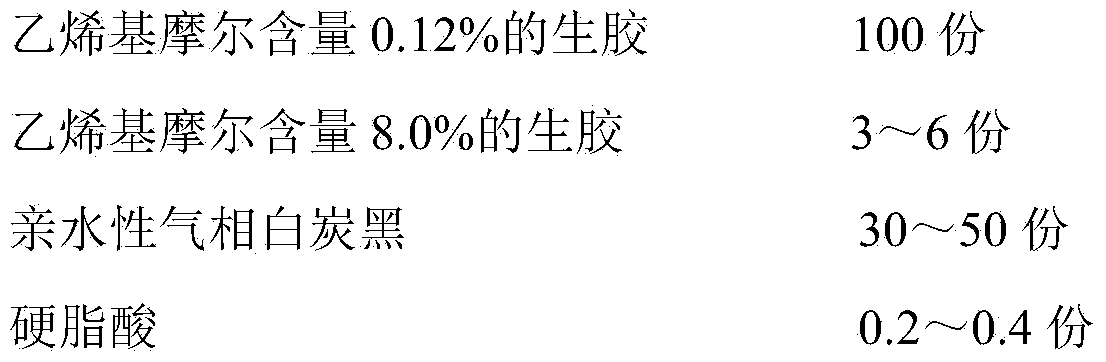

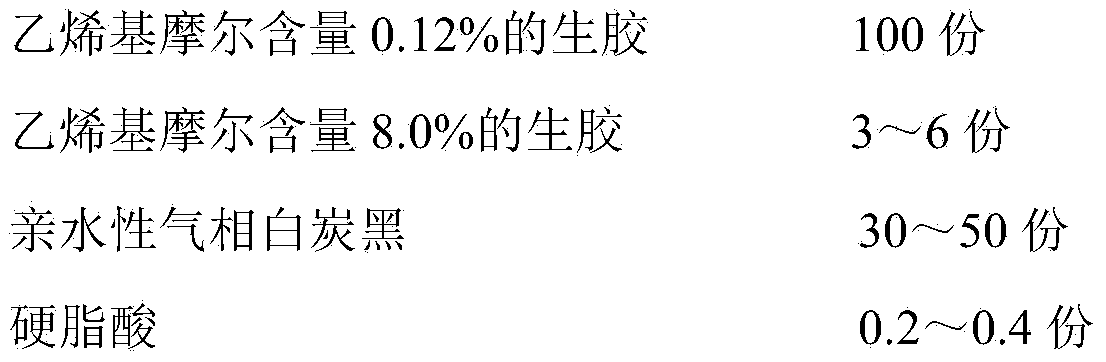

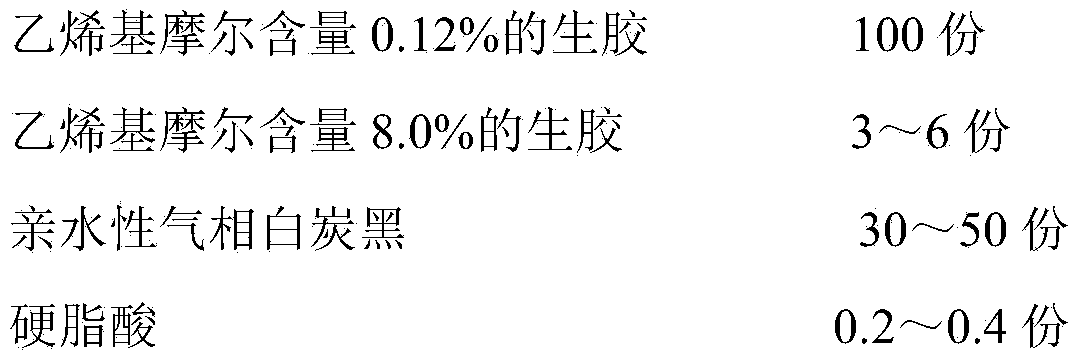

[0018] The preparation method of above-mentioned water vapor resistant silicone rubber, comprises the steps:

[0019] Step 1, adding 100 parts by mass of raw rubber with a vinyl molar content of 0.12% and 3 to 6 parts by mass of raw rubber with a vinyl molar content of 8.0% into a kneader and stirring for 0.2 to 0.4 minutes;

[0020] Step 2, adding 30-50 parts by mass of hydrophilic fumed silica and 0.2-0.4 parts by mass of stearic acid in 3-6 times, stirring thoroughly after each addition, to obtain a silicone rubber mix;

[0021] Step 3, cooling to room temperature after the glue is released, to obtain the water vapor resistant silicone rubber.

[0022] The steam-resistant silicone rubber prepared by the present invention can be added with a vulcanizing agent during use, and vulcanized at 175° C. for 5 minutes.

[0023] The raw rubber with a vinyl molar content of 0.12% involved in the examples was purchased from Jiangsu Tianchen Silicon Material Co., Ltd., model DV0.12; th...

Embodiment 1

[0025] 1. Add 100 parts by mass of raw rubber with a vinyl molar content of 0.12% and 3 parts by mass of raw rubber with a vinyl molar content of 8.0% into a kneader and stir for 0.3 minutes;

[0026] 2. Add 50 parts by mass of hydrophilic fumed silica and 0.2 parts by mass of stearic acid in 4 times, and stir thoroughly after each addition to obtain a silicone rubber compound;

[0027] 3. Cool to room temperature after the glue is released to obtain the water vapor resistant silicone rubber.

[0028] Add the vulcanizing agent to the water vapor resistant silicone rubber prepared in this example, vulcanize at 175°C for 5 minutes, and conduct a performance test. The results are shown in the following table:

[0029]

[0030]

[0031] Then, after steam treatment at 175°C for 2 hours, the performance test was carried out. The results are shown in the following table:

[0032]

Embodiment 2

[0034] 1. Add 100 parts by mass of raw rubber with a vinyl molar content of 0.12% and 6 parts by mass of raw rubber with a vinyl molar content of 8.0% into a kneader and stir for 0.4 min;

[0035] 2. Add 50 parts by mass of hydrophilic fumed silica and 0.4 parts by mass of stearic acid in 6 times, and stir thoroughly after each addition to obtain a silicone rubber compound;

[0036] 3. Cool to room temperature after the glue is released to obtain the water vapor resistant silicone rubber.

[0037] Add the vulcanizing agent to the water vapor resistant silicone rubber prepared in this example, vulcanize at 175°C for 5 minutes, and conduct a performance test. The results are shown in the following table:

[0038]

[0039] Then, after steam treatment at 175°C for 2 hours, the performance test was carried out. The results are shown in the following table:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com