A biomass raw material processing method and a system thereof

A biomass raw material and processing system technology, applied in the field of biomass raw material processing, can solve problems such as limited dehydration capacity, low energy efficiency, unstable biomass drying and grinding technology, etc., to reduce total investment, improve processing efficiency, reduce The effect of operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

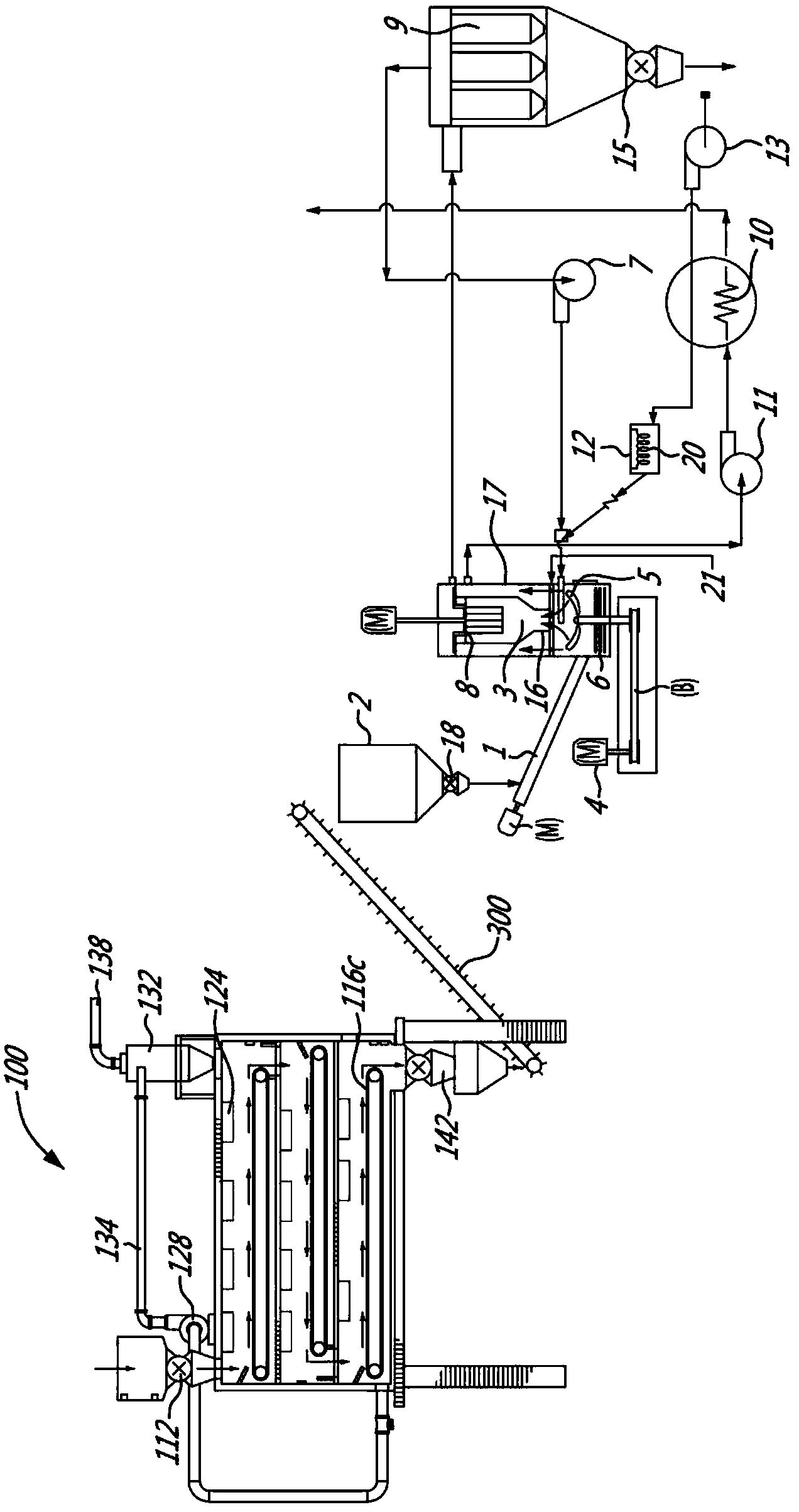

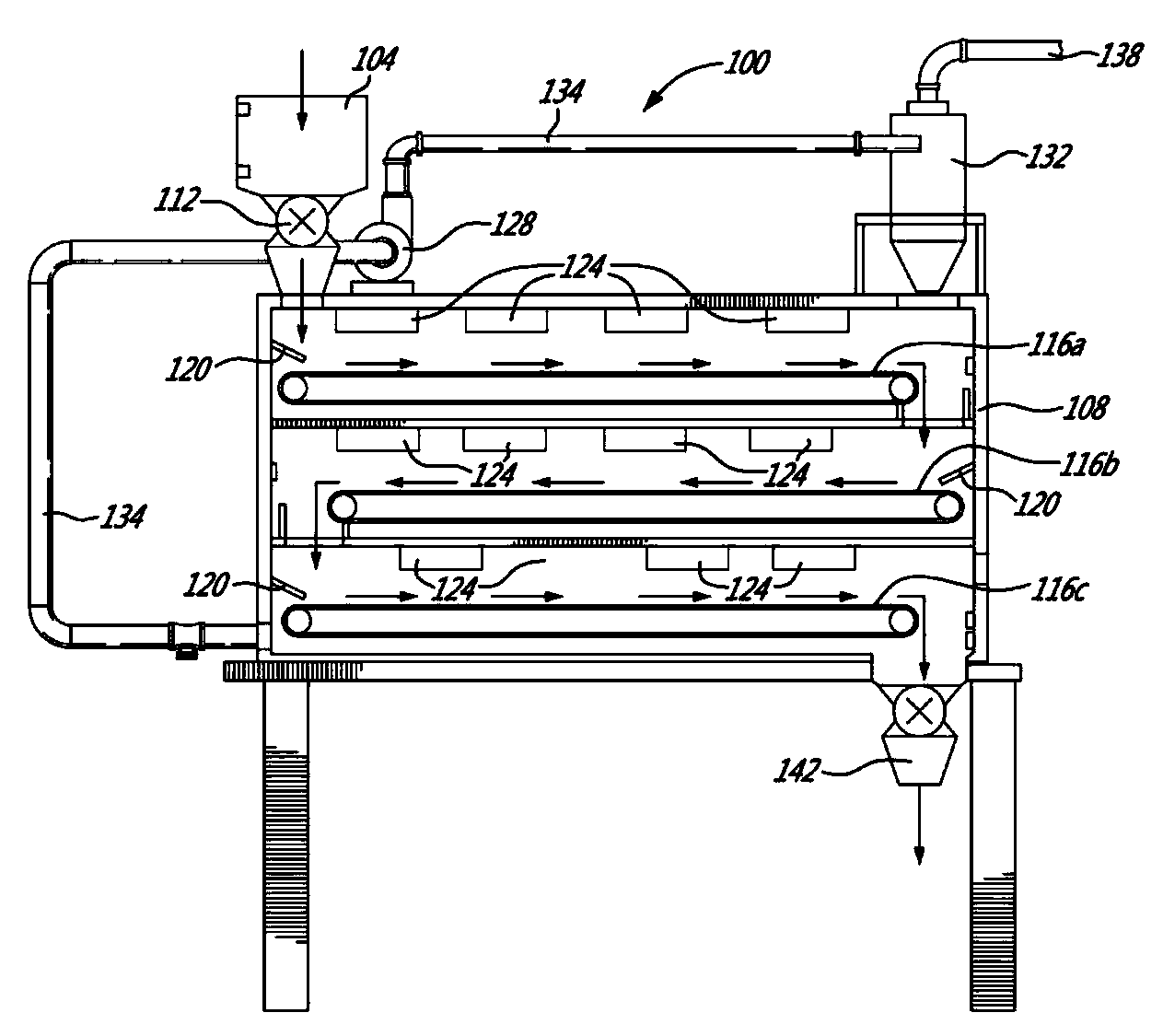

[0026] The following is attached Figures 1 to 3 The biomass raw material processing system and method of the present invention are described in detail.

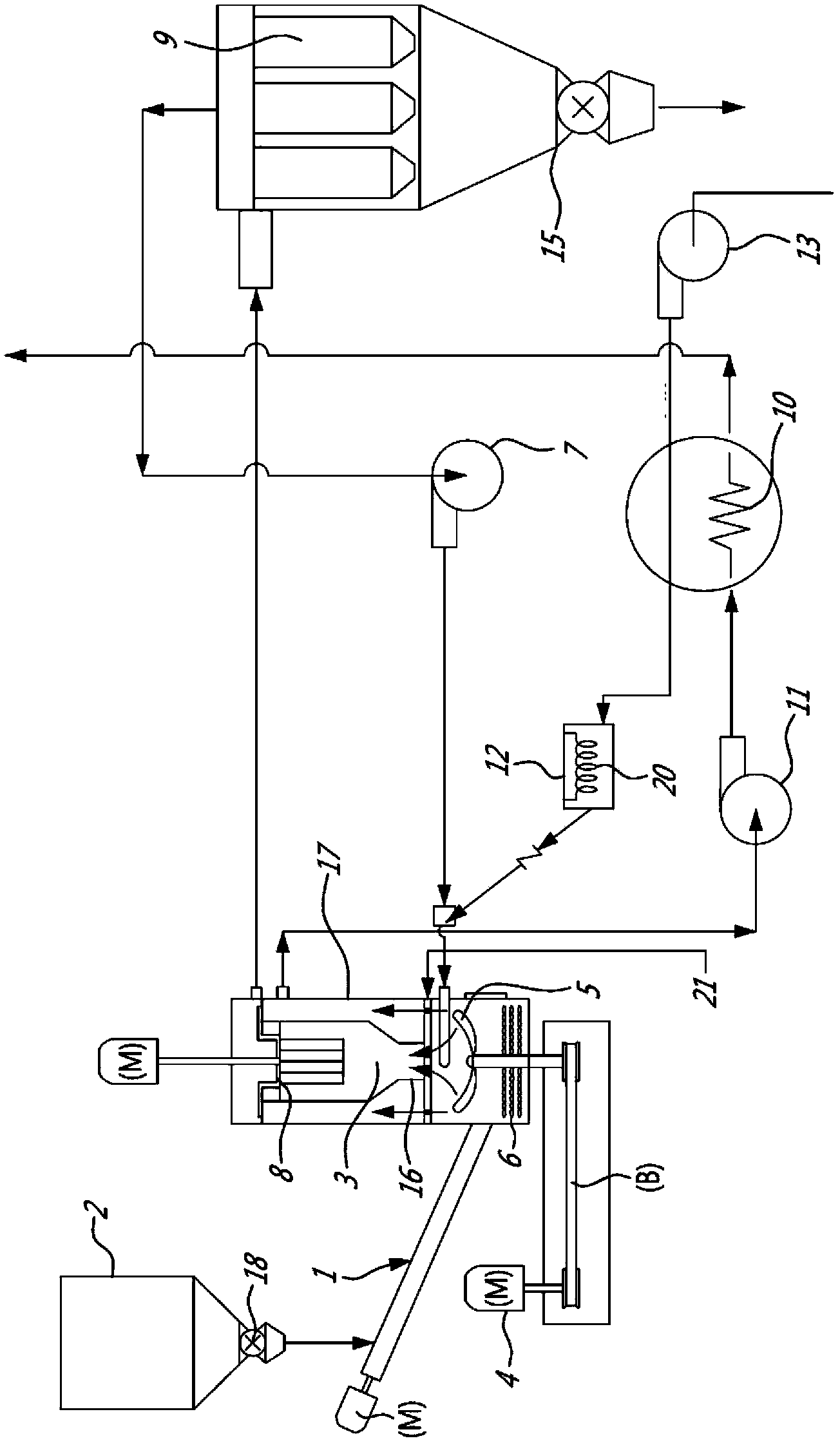

[0027] figure 1 Shown is the first embodiment of the biomass raw material processing system of the present invention. The biomass raw material is stored in the feed hopper 2 and enters the biomass raw material processing system through the conveyor 1 (such as a screw conveyor). The star feeder 18 at the bottom of the feeding hopper 2 unloads the biomass raw material in the conveyor 1 , and then transports the biomass, especially large pieces of biomass, to the bottom of the main chamber 3 .

[0028] The lower half of the main chamber 3 is fitted with a vertical shaft on which the blades 5 and the chain 6 are attached. Using the energy transmission system 4 composed of pulleys (such as a composite belt drive (B) plus a motor (M)), the main shaft can rotate at a high speed higher than 1200rpm and drive the chain 6 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com