A high-power bipolar pulse magnetron sputtering method

A bipolar pulse and magnetron sputtering technology is applied in the field of bipolar pulse magnetron sputtering to achieve the effects of high bonding force, suppressing sparking phenomenon and improving sputtering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

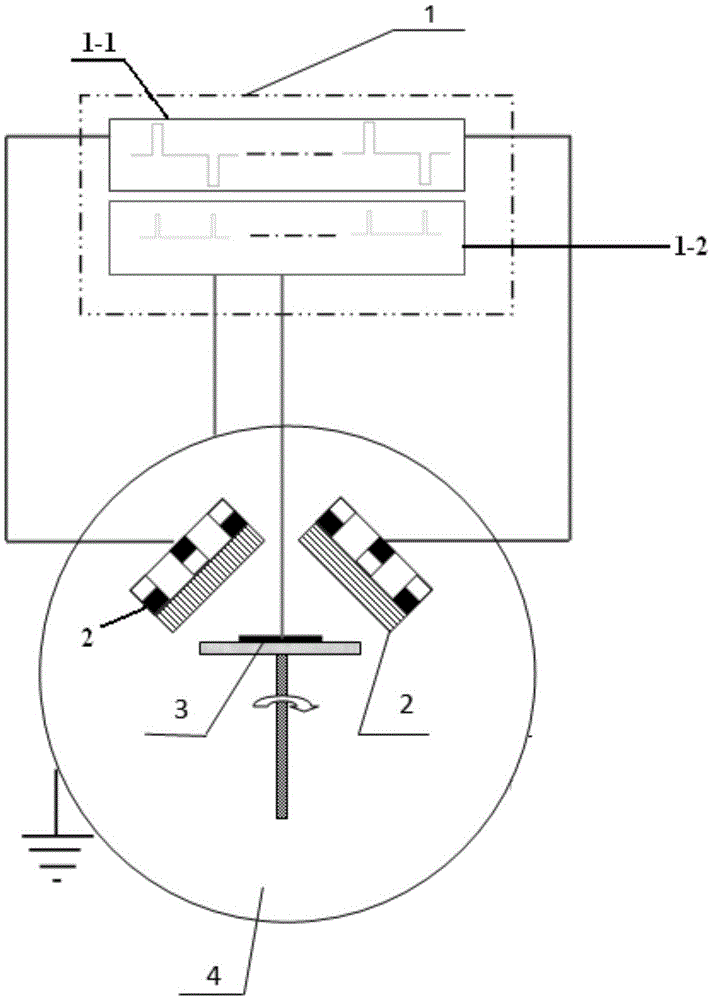

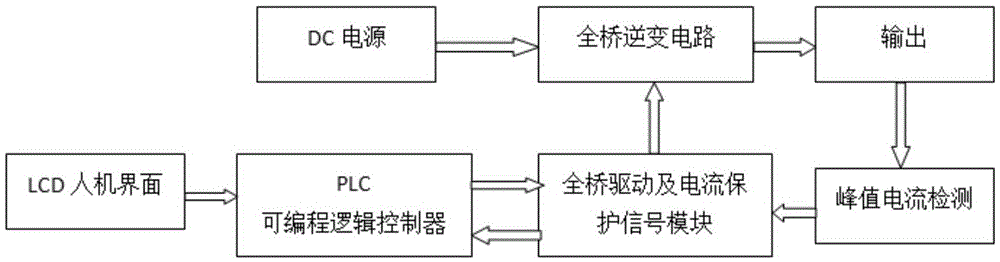

[0018] Specific implementation mode one: this implementation mode is a kind of high-power bipolar pulse magnetron sputtering method, is specifically carried out according to the following steps:

[0019] 1. Installation equipment: fix the cleaned sample on the rotatable sample stage in the vacuum chamber, the cathode of the bias power supply is connected to the sample stage, and the anode of the bias power supply is grounded; install twin targets, and set the target base distance to 3cm to 20cm , set the shortest horizontal distance between the twin targets to 1cm to 20cm; connect the twin targets to the two output terminals of the sputtering power supply respectively; the angle between the twin targets is 10° to 180°;

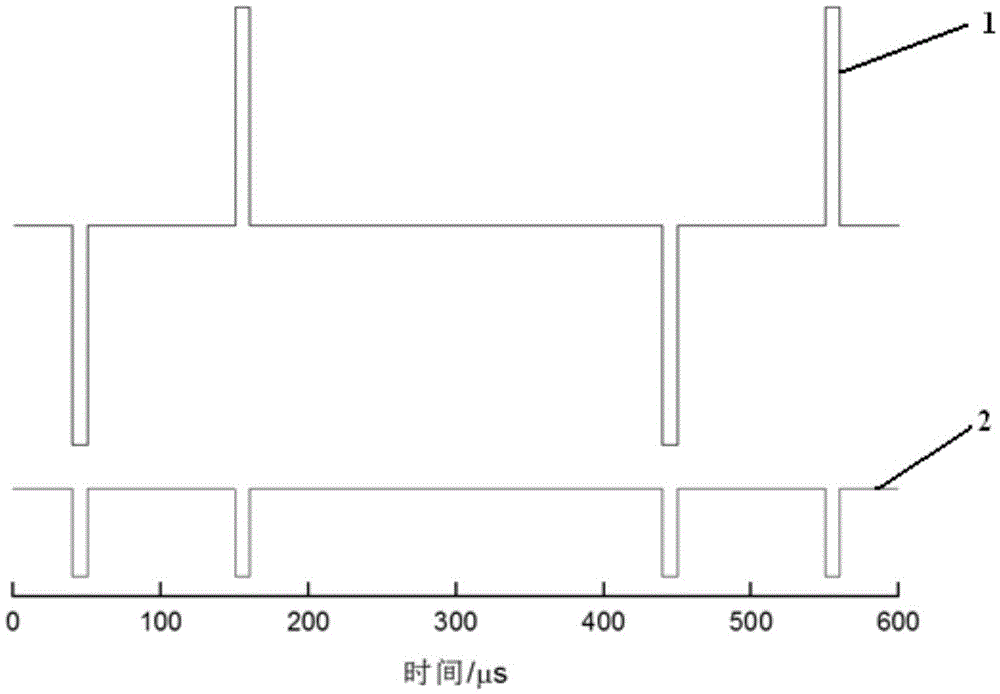

[0020] 2. Set the power supply parameters: set the pulse width of the positive and negative bidirectional pulses of the sputtering power supply to be the same and both are greater than 0ms and less than or equal to 5ms. Set the time interval of the positive and...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, twin targets are installed, the target base distance is set to be 8 cm to 15 cm, and the shortest horizontal distance between the twin targets is set to 8 cm to 15 cm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step two, the pulse width of the positive and negative bidirectional pulses of the sputtering power supply is set to be the same and both are 10 μs to 1 ms, and the time of the positive and negative pulses of the sputtering power supply is set The interval is 10μs~1ms. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com