Preparation method for hydrogen-contained and aluminum-doped type diamond film

A diamond film and substrate technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as the inability to guarantee the doping content of diamond-like carbon films, the inability to sputter Al atoms, and health hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

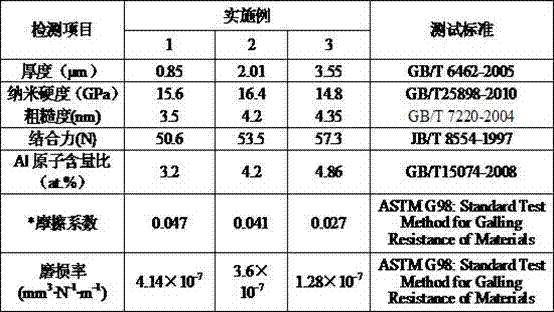

Examples

Embodiment 1

[0014] 1. After degreasing and drying the mold steel sheet, fix it on the sample turret in the vacuum chamber, and then pump the background vacuum to 2.5×10 -3 Pa;

[0015] 2. Put argon gas into the ion source, turn on the ion source power supply and adjust its current to 1.0A, keep the pressure in the furnace at 0.3Pa, turn on the substrate pulse bias power supply and gradually increase it to -700V, and perform ion bombardment cleaning on the surface of the sample 20 minutes;

[0016] 3. Turn on the intermediate frequency power supply of the aluminum target, adjust its current to 1.0A, pass methane gas (30sccm) and argon gas (80sccm) into the ion source, keep the ion source current at 1.0A, and keep the substrate bias at -100V, and work The gas pressure was 0.35 Pa, and the hydrogen-containing aluminum-doped diamond-like carbon film was deposited for 60 minutes; after the deposition, the target and bias power were turned off and the vacuum was maintained, and the sample was ...

Embodiment 2

[0018] 1. After the stainless steel sheet is cleaned and dried with ultrasonic assistance in acetone, it is fixed on the sample turntable in the vacuum chamber, and the background vacuum is pumped to 3.0×10 -3 Pa;

[0019] 2. Put argon gas into the ion source, turn on the ion source power supply so that the current is 1.5A, keep the pressure in the furnace at 0.4Pa, turn on the substrate pulse bias power supply and gradually increase it to -800V, and perform ion bombardment cleaning on the surface of the sample for 30 minute;

[0020] 3. Then feed methane gas with a flow rate of 50sccm and argon gas with a flow rate of 100sccm into the ion source, adjust the aluminum target current to 2.0A, the substrate bias voltage to -150V, and the working pressure to 0.44Pa to deposit hydrogen-containing aluminum-doped diamond-like carbon films 120 minutes; after the deposition, turn off the target and bias power supply, keep the vacuum, and after the sample cools down to room temperature...

Embodiment 3

[0022] 1. After cleaning and drying the hard alloy steel sheet with ultrasonic assistance in acetone, fix it on the sample turret in the vacuum chamber, and pump the background vacuum to 3.0×10 -3 Pa;

[0023] 2. Put high-purity argon gas into the ion source, turn on the ion source power supply and adjust its current to 1.5A, keep the pressure in the furnace at 0.4Pa, turn on the substrate pulse bias power supply and gradually increase it to -800V, and perform ionization on the surface of the sample. Activation by bombardment for 30 minutes;

[0024] 3. After ion cleaning, flow 60sccm acetylene gas and 120sccm argon gas into the ion source, and adjust the aluminum target current to 3.0A, the substrate bias voltage to -200V, the ion source current to 1.5A, and the working pressure to 0.5 Pa, deposit hydrogen-containing Al-doped diamond-like carbon film for 240 minutes; after the deposition, turn off the target and bias power, keep the vacuum, and take out the sample after cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com