Method and device for removing solids from pickling liquid for cold-drawn and cold-rolled steel pipes

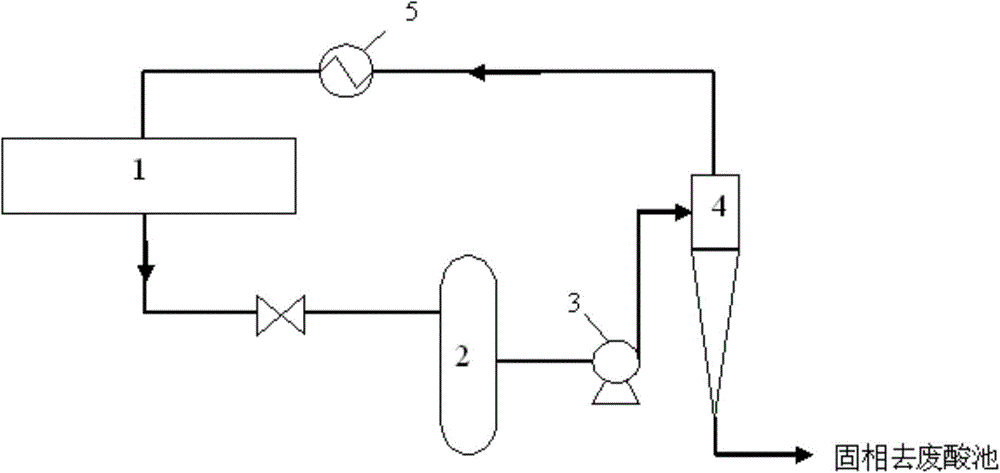

A pickling solution and removal technology, which is applied to the desolidification device of cold-rolled and cold-drawn steel pipe pickling solution, the removal of solid particles, and the field of pickling solution desolidification, which can solve the problems that cannot meet the needs of industrial production Solve the problems of scientific purification and treatment of cold-drawn and cold-rolled steel pipe pickling liquid, and achieve the effects of small footprint, compact and reasonable structural design, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] In most pickling process production lines, the content of solid particles in the pickling tank is relatively high. If the solid particles stay in the pickling tank for a long time, iron oxides will react with dilute sulfuric acid to form sulfate, etc., and sulfate exists in the form of ions . An important test index for the effectiveness of the pickling solution is the concentration of iron ions. When the concentration of iron ions reaches a certain peak value, the pickling solution will fail. It is necessary to discharge all the pickling solution and re-add dilute sulfuric acid for production.

[0034] A large amount of hydrogen gas generated during the pickling process makes the oxide skin on the surface of the steel pipe burst and loose, and has a mechanical peeling effect on the oxide skin on the surface of the steel pipe. In order to fully discharge the solid particles in the pickling tank and improve the removal rate of iron filings, the pipeline for discharging t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com