Cofferdam construction method with grooves milled through limited hole forming of percussion drill combined with steel sheet piles

A steel sheet pile cofferdam and construction method technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems that cannot meet the needs of construction, cannot achieve water sealing, and the difficulty of bottom sealing concrete, etc., and achieve simple and fast construction process and easy construction quality The effect of controlling and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

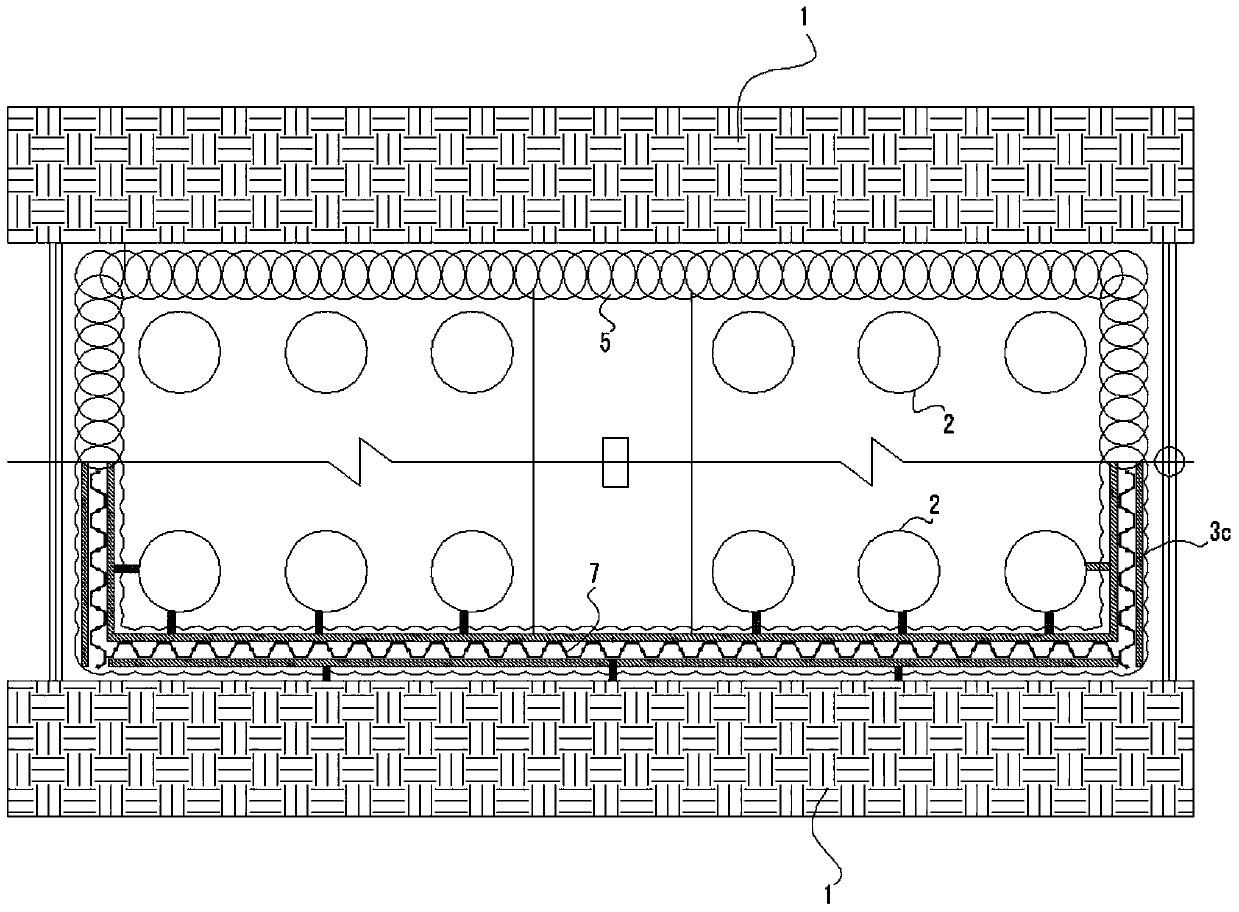

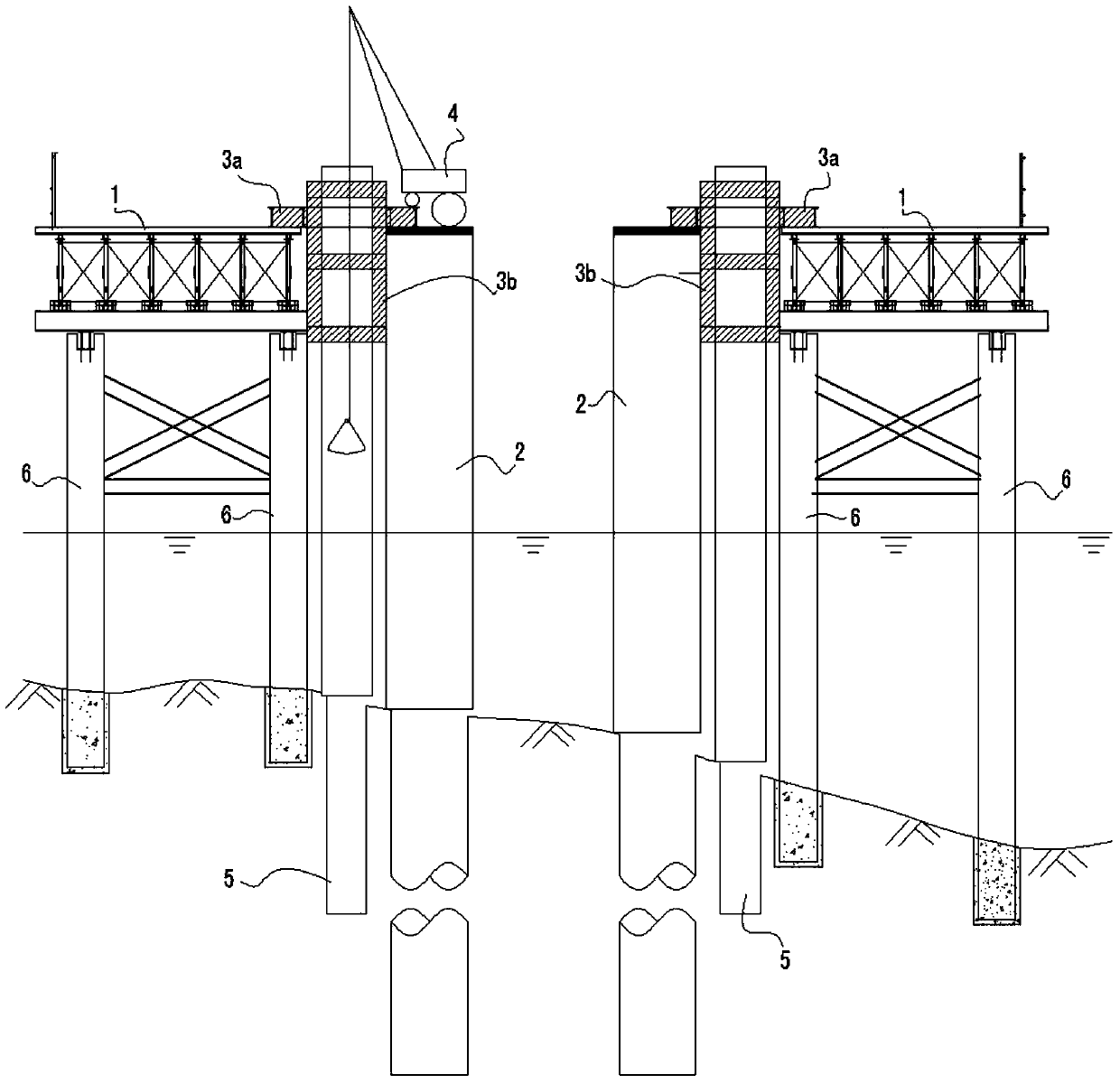

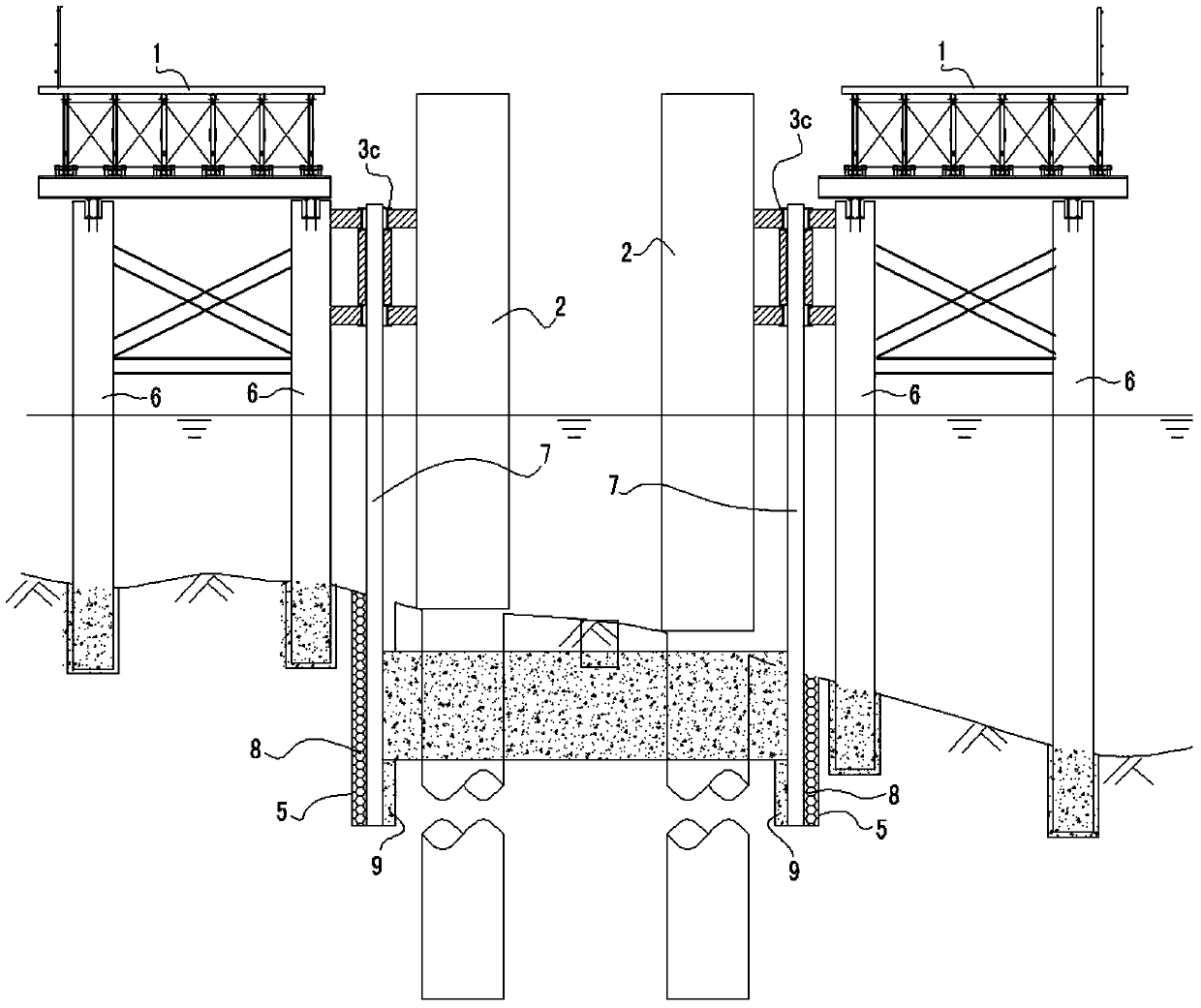

[0029] see figure 1 , figure 2 and image 3 In this embodiment, the cofferdam construction method combined with impact drilling to limit hole-forming and milling slots combined with steel sheet piles is: use the steel trestle platform 1 and the main bridge steel casing 2 as supports, and use the impact drill to limit the position according to the plane position of the cofferdam Hole forming, through the limit hole forming at two phase-staggered positions, milling grooves 5 for fixing steel sheet piles are formed on the rock surface and river bed according to the plane position of the cofferdam, and steel sheet piles are inserted one by one in the milling grooves to form steel sheet cofferdams Then, in the milling groove, the outer side of the steel sheet pile cofferdam is filled with bagged clay 8; finally, the bottom sealing concrete is poured inside the steel sheet pile cofferdam to seal the water.

[0030] In this embodiment, the specific implementation is carried out ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com