Basement sump structure

A sump and basement technology, applied in the field of building waterproofing and drainage, can solve problems such as increasing economic costs and construction period, reducing economic benefits, and weakening the stability of the bottom plate structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

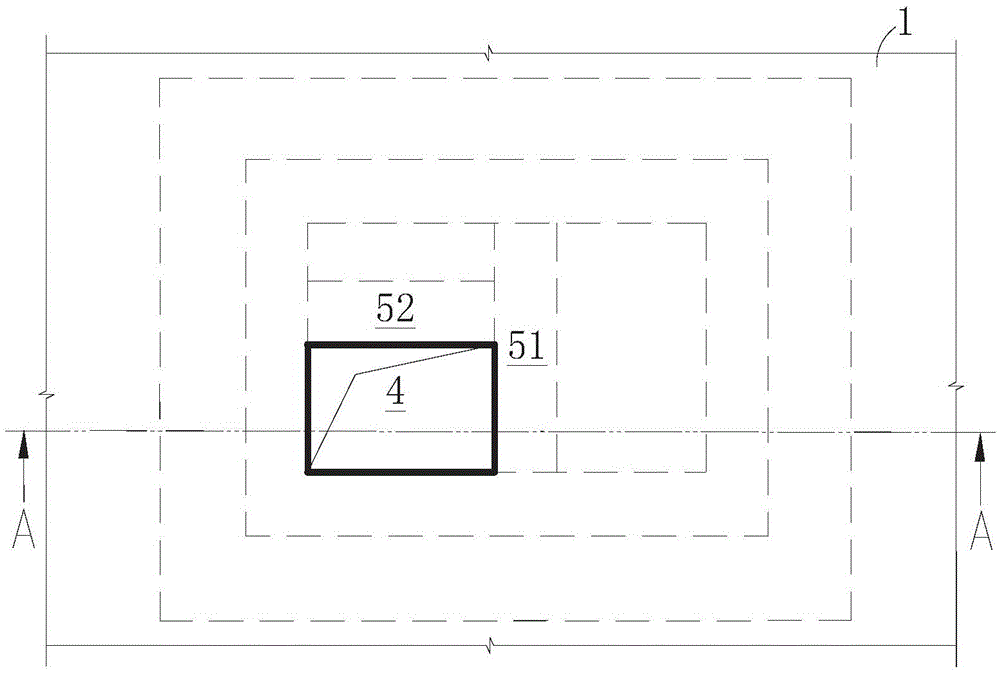

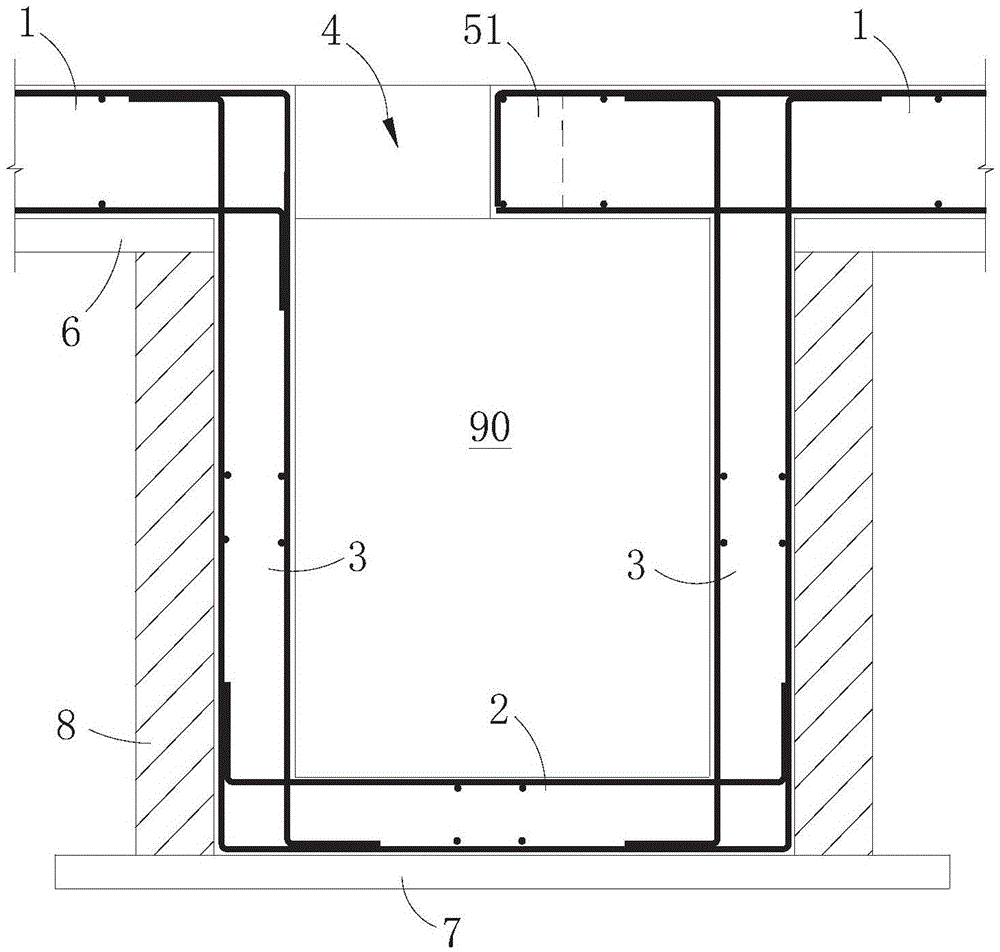

[0032] Such as Figure 1 to Figure 2 As shown, this embodiment is a basement sump structure, which is arranged under the basement floor 1 for temporarily storing sewage or miscellaneous water, and includes a sump main body fixed under the basement floor 1 . The sump main body includes a bottom plate 2 and a side wall 3 enclosing a sump chamber 90 . The water collecting cavity 90 is a cavity with an upper opening, the upper edge of the side wall 3 is fixedly connected to the basement floor 1, and the basement floor 1 is provided with a hole 4 at the opening above the water collecting cavity 90, and the area of the hole 4 ( Size) is smaller than the area (size) of the opening of the sump cavity.

[0033]In the present invention, the dimension at the maximum width of the pit opening 4 is less than 1000mm. In this embodiment, the pit mouth 4 is rectangular, and its size is less than or equal to 1000mm*1000mm. In order to further reduce the impact of the pit opening on the str...

Embodiment 2

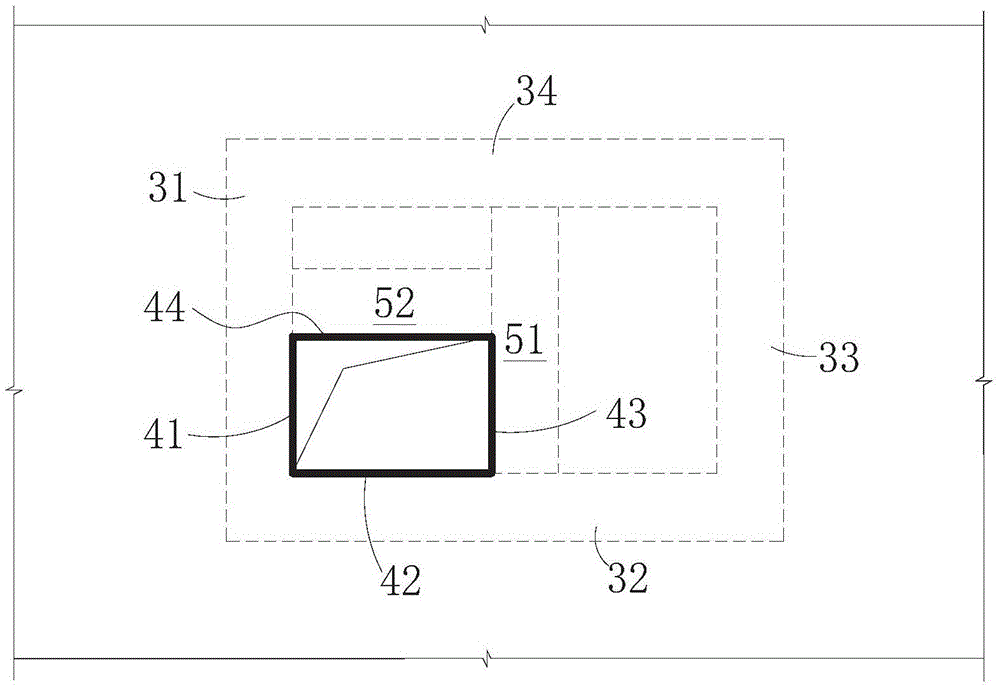

[0043] Such as Figure 4 As shown, the only difference between this embodiment and Embodiment 1 is that in this embodiment, the upper edge of the side wall 3 of the sump main body forms a circle, and the side wall 3 is formed by a vertical ring Constructed of reinforced concrete walls. The pit mouth 4 that the basement floor 1 opens at the opening above the water collection cavity is also circular in shape, the diameter of the pit mouth 4 is smaller than the diameter of the circle formed by the upper edge of the side wall 3, and the diameter of the pit mouth 4 is less than 1000mm, Specifically 700mm. In addition, two parallel supporting dark beams 51 and 52 are arranged in the basement floor part between the upper edge of the side wall 3 and the edge of the pit mouth 4. The two supporting dark beams are tangent to the pit mouth 4 and straddle the catchment The top of the main body of the pit is open and connected to two points on the upper edge of the side wall 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com