Sectionalized electrical heating regeneration device for diesel particulate filter

A particle trap and electric heating device technology, which is applied to exhaust devices, mufflers, machines/engines, etc., can solve problems such as complex structures, and achieve the effects of simple device structure, convenient disassembly and assembly, and low regenerative power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

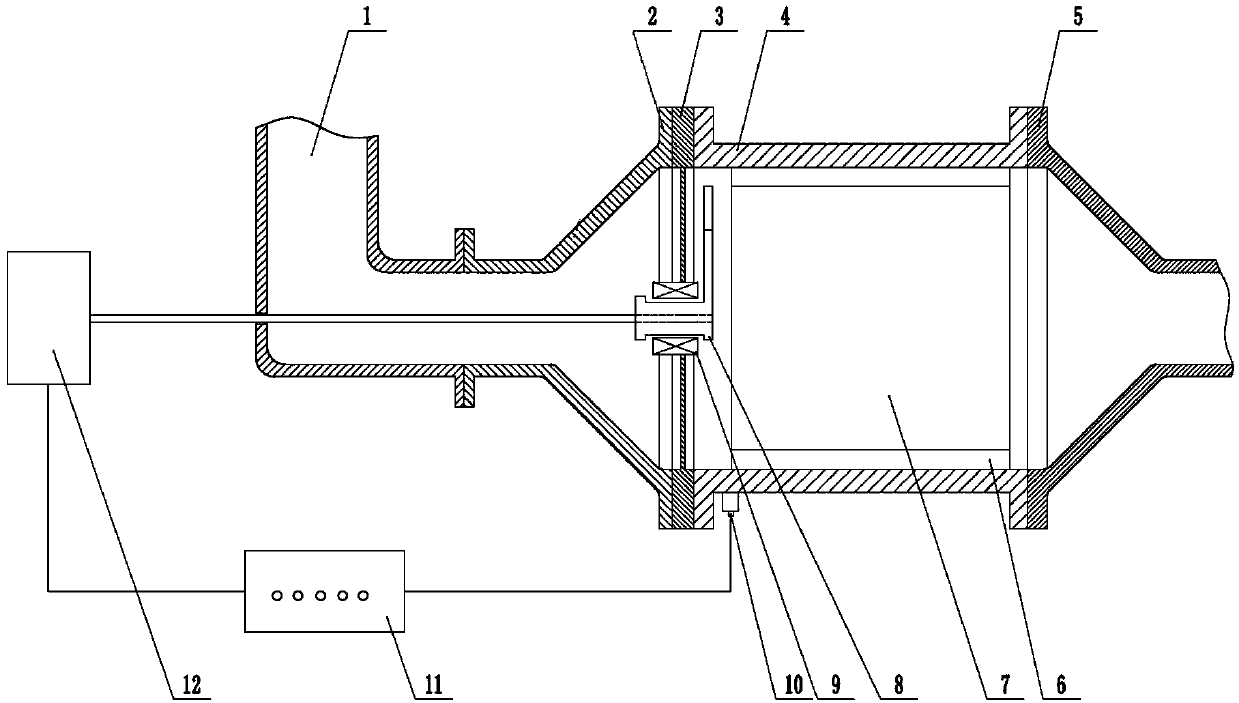

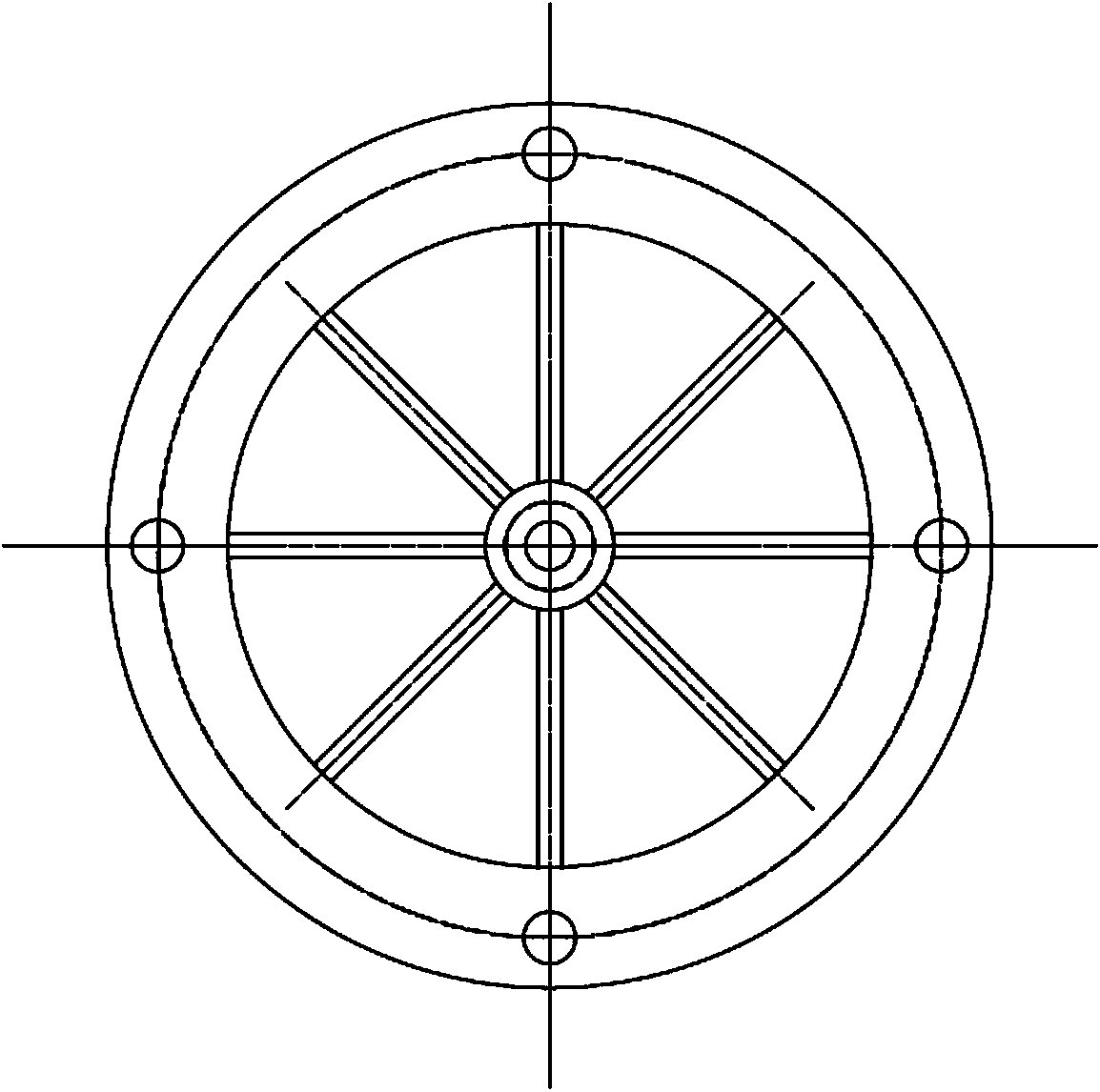

[0022] figure 1 A diesel engine particulate filter partition electric heating regeneration device is shown, including an electric heating device, an engine exhaust intake pipe 1 is connected to the small end of a conical intake reducing pipe 2, and a large end of the intake reducing pipe is provided. There is an air inlet flange, the large end of the conical air outlet reducing pipe 5 is provided with an air outlet flange, and the front and rear flanges of the cylindrical packaging shell 4 are respectively larger than the air inlet reducing pipe 2. The air inlet flange on the end and the air outlet flange on the large end of the outlet reducing pipe 5 are connected by bolts. The support plate 3 is composed of a ring and a plurality of spokes arranged radially on the inner port of the ring. See Figure 2a , Figure 2b , the annular part of the support plate 3 is clamped between the air inlet flange on the large end of the air inlet reducing pipe 2 and the front end flange of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com