LED bulb

A technology of LED light bulbs and bulbs, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of easy air leakage or breakage, difficult helium sealing process, and limited heat exchange capacity, etc., to achieve Reduces thermal resistance, eliminates LED glare, improves cooling and light scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

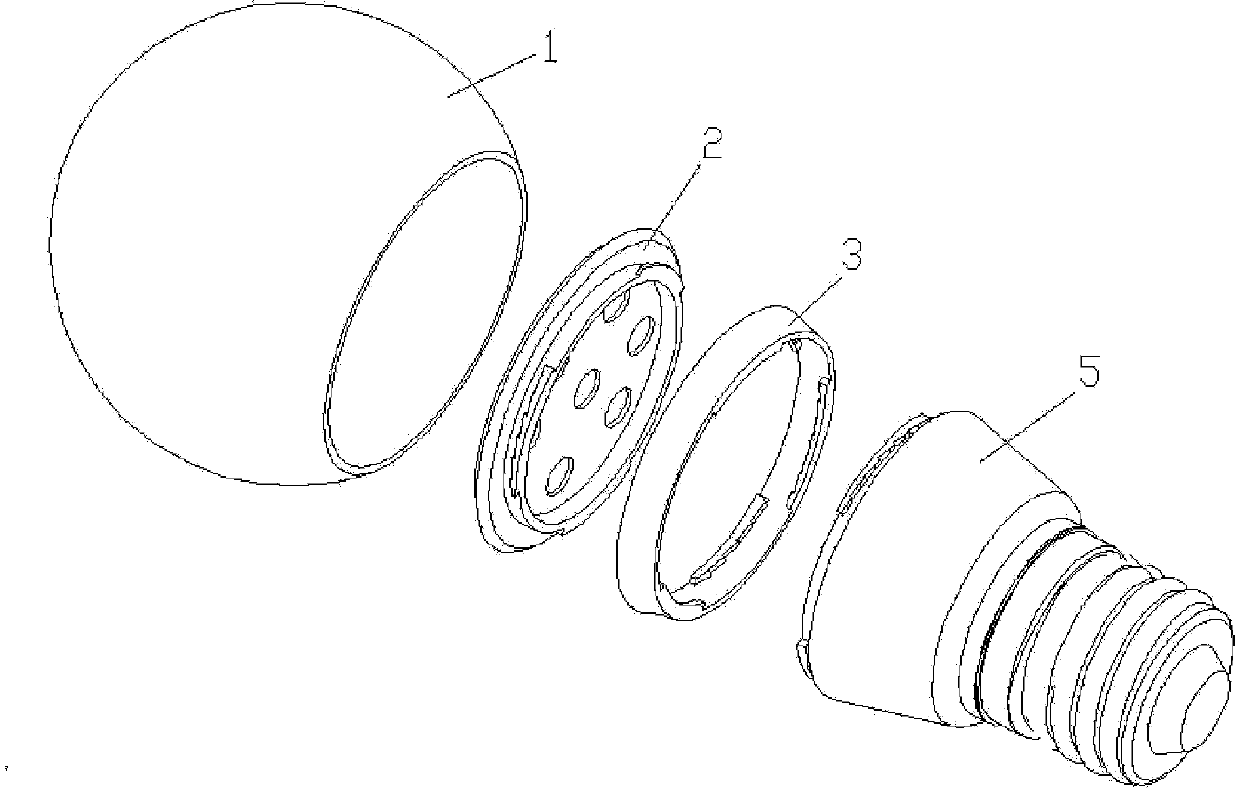

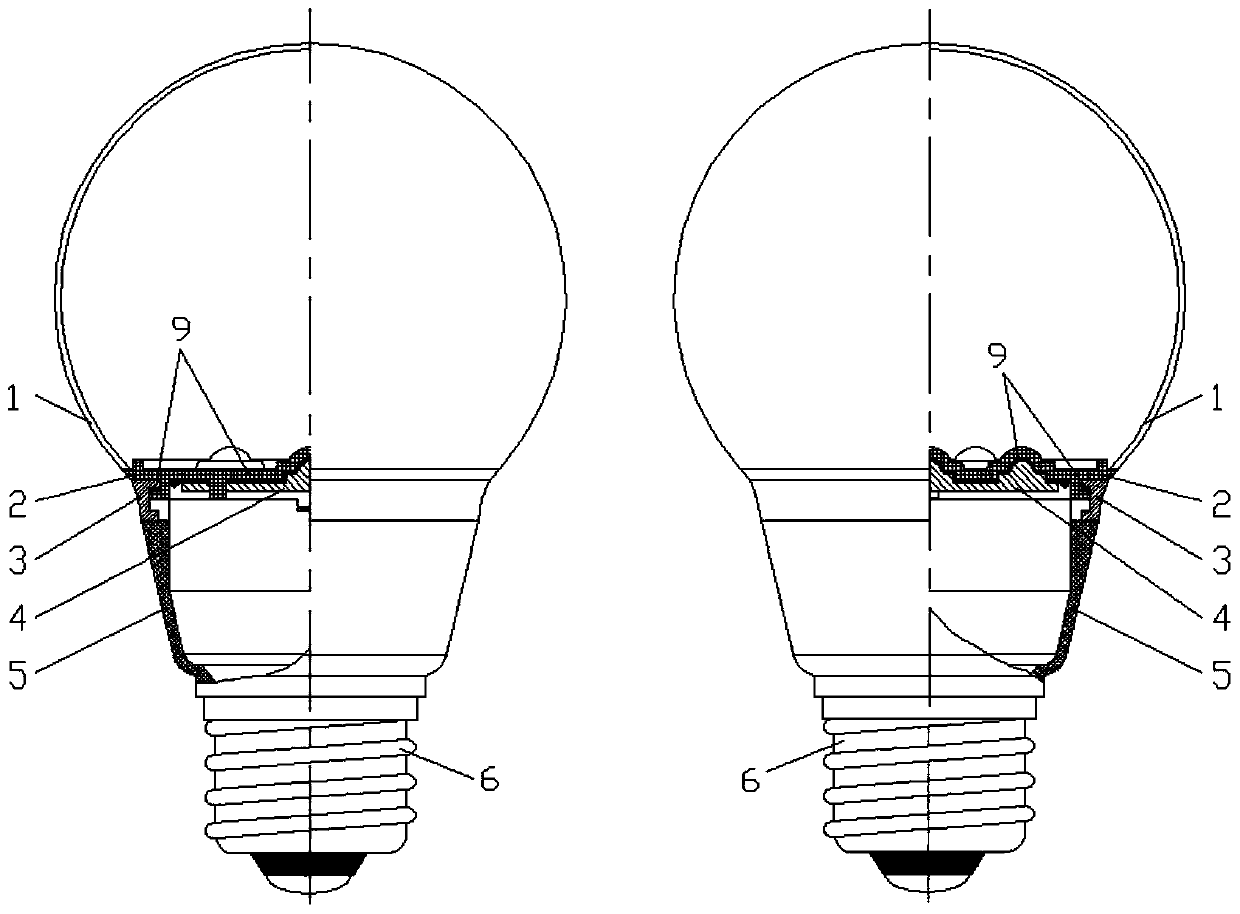

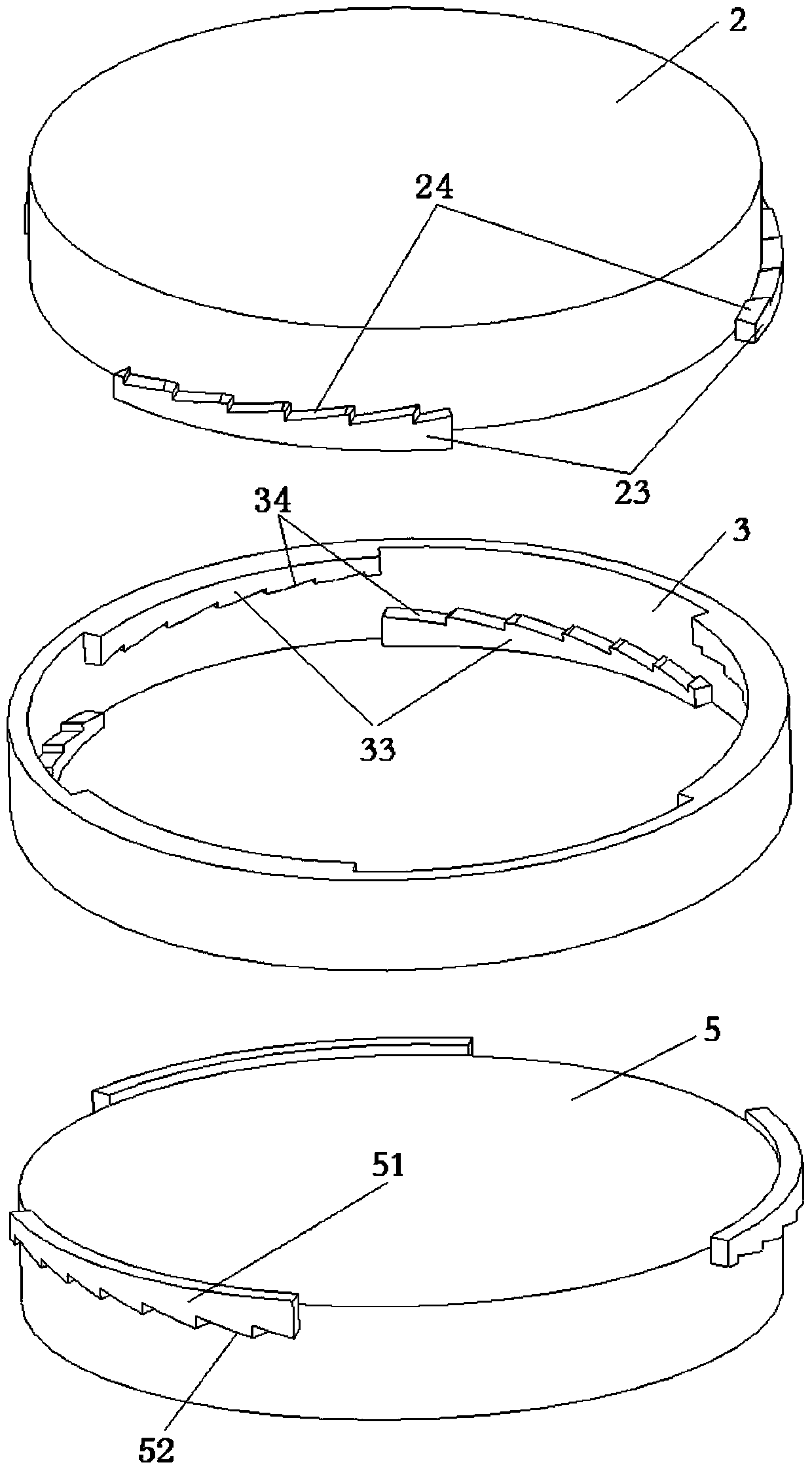

[0030] figure 1 , figure 2 It is a schematic diagram of the overall structure of the LED light bulb of the present invention, including a heat dissipation optical module, a photoelectric conversion module and a locking ring 3. The heat dissipation optical module includes a transparent bulb cover 2 and a bulb shell 1, a transparent bulb cover 2 and a bulb shell 1 Sealed to form a sealed cavity, the sealed cavity is filled with transparent liquid; the photoelectric conversion module includes a cylindrical shell 5, the lower end of the cylindrical shell 5 is equipped with a standard lamp holder 6 connected to an external power supply, and the cylindrical shell 5 contains There is an electronic driver (not shown), the upper end surface of the cylindrical shell 5 is equipped with a planar light-emitting substrate 4, and the LED light-emitting ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com