Measuring system for expansion coefficient of material

A technology of expansion coefficient and measurement system, applied in the direction of material thermal expansion coefficient, phase influence characteristic measurement, etc., can solve problems such as no research on thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

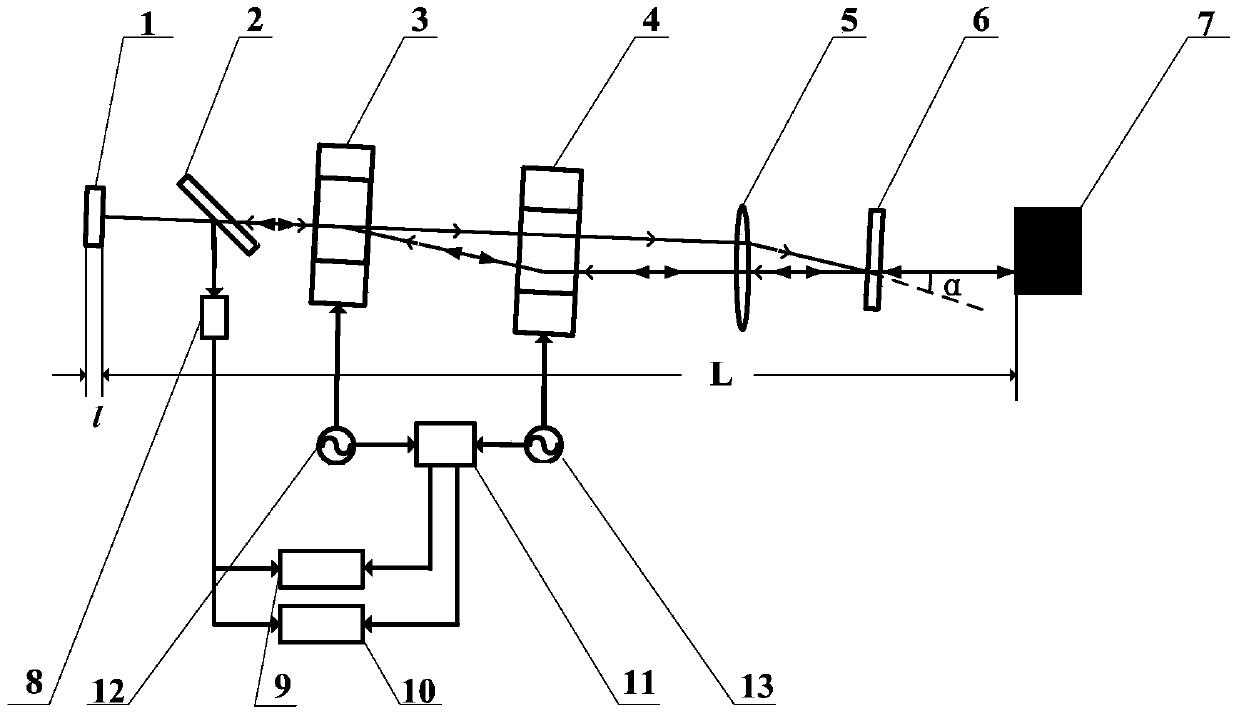

Problems solved by technology

Method used

Image

Examples

Embodiment 1

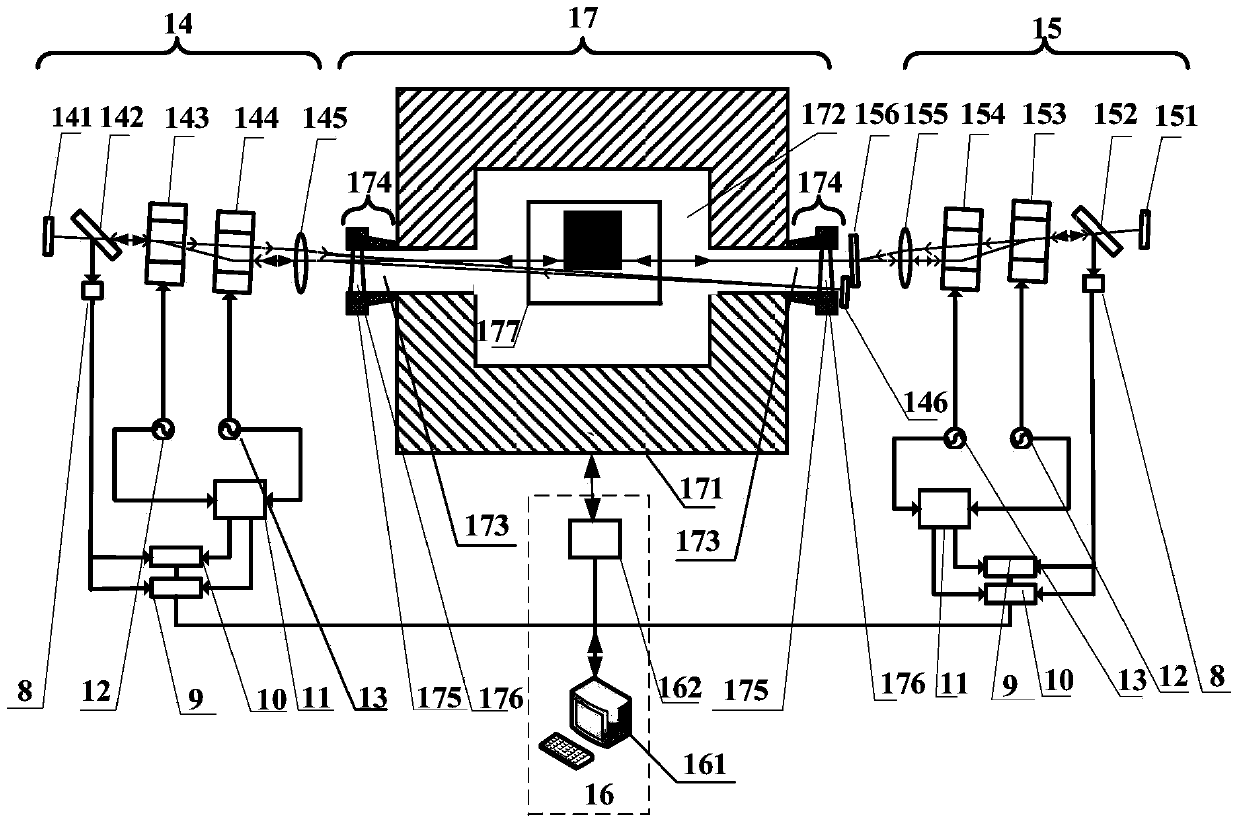

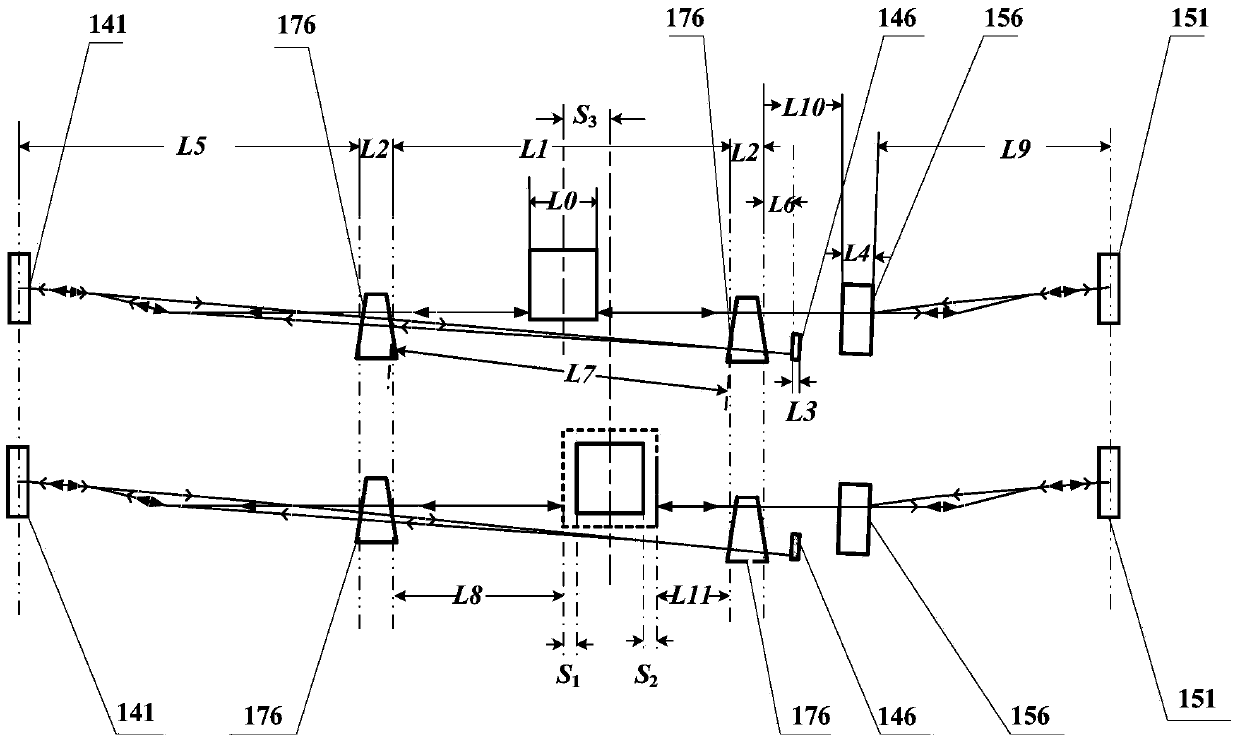

[0040] Such as figure 2 As shown, Embodiment 1 of the present invention includes first and second solid microchip laser feedback interferometer optical systems 14, 15 and an electrical measurement and electronic control system 16, and a solid microchip laser feedback interferometer optical system is arranged between The heating furnace 17, the heating furnace 17 includes a furnace 171, a cavity 172 is arranged inside the furnace 171, a perforation 173 is arranged symmetrically outward on the two opposite sides of the cavity 172, and a perforated packaging structure 174 is fixedly arranged on the outer end of each perforation 173 , the outer end of each perforated packaging structure 174 fixes a window 176 through a window holder 175, a sample stage device 177 capable of placing the sample to be tested is also arranged in the cavity, and a heating element is also fixedly suspended in the furnace 171 and a temperature sensor (not shown in the figure).

[0041] The first solid-st...

Embodiment 2

[0071] Such as Figure 4As shown, the structure of Embodiment 2 of the present invention is basically the same as that of Embodiment 1, and it includes first and second solid-state microchip laser feedback interferometer optical systems 18, 15 and electrical measurement and electrical control system 16. The difference is The structure of the first solid microchip laser feedback interferometer optical system 18 adopted in this embodiment is different. The first solid microchip laser feedback interferometer optical system 18 in the present embodiment adopts the second solid microchip in embodiment The optical system 15 of the laser feedback interferometer has the same structure, and the structure and principle of the electric measurement and electric control system 16 are the same as those in Embodiment 1, and will not be repeated here.

[0072] The first solid-state microchip laser feedback interferometer optical system 18 of the present embodiment includes several optical elem...

Embodiment 3

[0084] Such as Figure 6 As shown, Embodiment 3 of the present invention includes a microchip laser feedback interferometer optical system 19 and an electrical measurement and electrical control system 16, and a heating furnace 20 is arranged below the solid microchip laser feedback interferometer optical system 19; the heating furnace 20 includes A furnace 201, a cavity 202 is arranged in the furnace 201, a perforation 203 is arranged on the top of the cavity 202 extending outward, and a perforation sealing structure 204 is fixedly arranged on the outer end of the perforation 203, and the outer end of the perforation sealing structure 204 passes through a window The sheet holding seat 205 fixes a window 206, and a sample stage device 207 capable of placing a reference object and a sample to be tested is also arranged in the cavity 202, and a heating element and a temperature sensor (not shown in the figure) are also fixedly suspended in the furnace 201. ); the electrical meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com