Single-component fiber-optic geophone, three-component fiber-optic microseismic geophone comprising same and three-component fiber-optic microseismic detection array also comprising same

A fiber optic detector, single-component technology, applied in seismic signal receivers and other directions, can solve the problems of large sensor volume, complex downhole system, low sensitivity, etc., and achieve the effect of high sensitivity, improved sensitivity, and strong wavelength division multiplexing capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

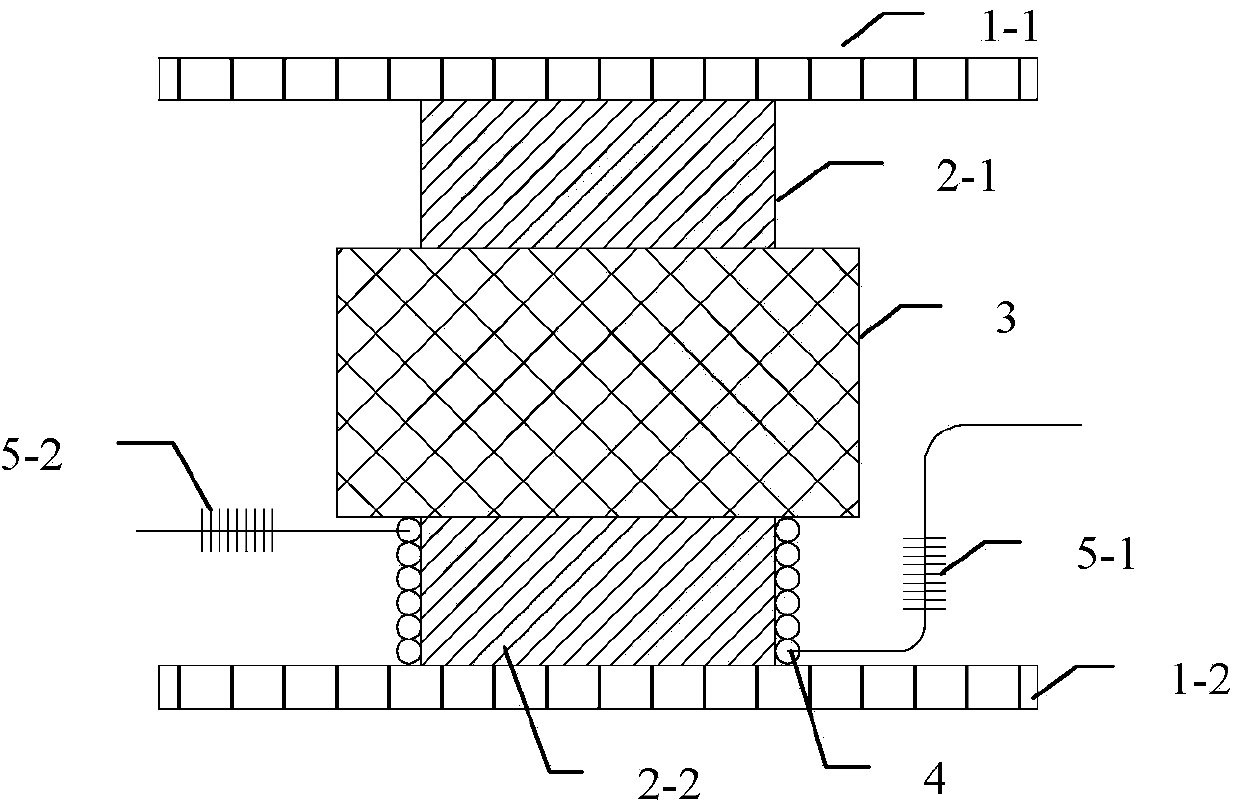

[0024] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, the single-component optical fiber detector described in this embodiment includes: No. 1 end frame 1-1, No. 2 end frame 1-2, No. 1 rubber column 2-1, and No. 2 rubber column 2 -2, quality block 3, fiber optic coil 4, No. 1 fiber Bragg grating 5-1 and No. 2 fiber Bragg grating 5-2;

[0025] One end of the No. 1 rubber column 2-1 and one end of the No. 2 rubber column 2-2 are respectively fixed on two parallel surfaces of the mass block 3, and the other end of the No. 1 rubber column 2-1 is fixed on the No. 1 end frame 1 -1 side, the other end of the No. 2 rubber column 2-2 is fixed on the side of the No. 2 end frame 1-2, the optical fiber coil 4 is wound on the surface of the No. 2 rubber column 2-2, and one end of the optical fiber coil 4 is connected to One end of the No. 1 Fiber Bragg Grating 5-1 and the other end of the Fiber Coil 4 are connected to one end of the No. 2 Fiber B...

specific Embodiment approach 2

[0034] Specific embodiment 2: This embodiment is a further description of the single-component fiber detector described in Specific Embodiment 1. In this embodiment, the center of the No. 1 Fiber Bragg Grating 5-1 and the No. 2 Fiber Bragg Grating 5-2 same wavelength.

specific Embodiment approach 3

[0035] Specific embodiment three: this embodiment is a further description of the single-component optical fiber detector described in specific embodiment one. In this embodiment, the shape of the mass block 3 is a cube or a cylinder, and the mass block 3 and The contact end surface area of the two rubber columns is larger than the end surface area of the two rubber columns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com