Constrained damping plate optimization design method based on bidirectional evolutionary optimization algorithm

A technology of constrained damping and optimization algorithm, applied in computing, instrumentation, electrical and digital data processing, etc., can solve the problems of recovery, affecting the reliability of optimization algorithm, inefficient local optimization of optimization results, etc., and achieve the effect of reasonable material layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

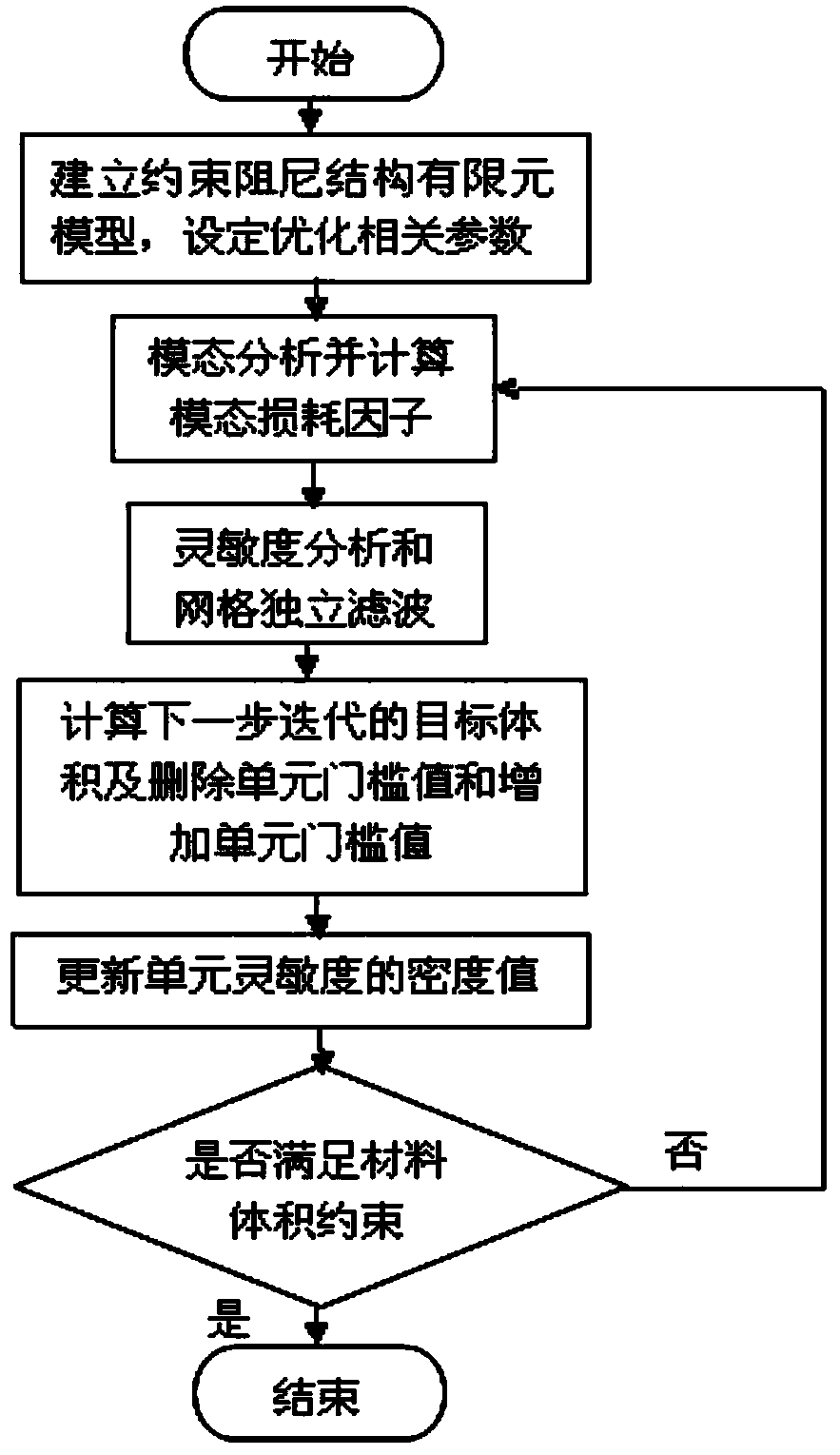

Method used

Image

Examples

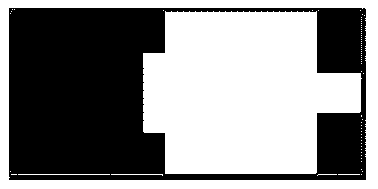

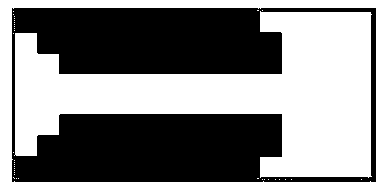

Embodiment 1

[0065] The substrate of the constrained damping cantilever plate is an aluminum plate with a length of 0.2m, a width of 0.1m, a thickness of 2mm, and a density of 2800kg / m 3 , the modulus of elasticity is 70e9Pa, and Poisson's ratio is 0.3. Cover the surface of the aluminum plate with constrained damping material, the thickness of the damping material is 0.3mm, and the density is 1200kg / m 3 , the modulus of elasticity is 12e6Pa, Poisson's ratio is 0.495, and the loss factor is 0.5. Constraint material thickness is 0.5mm, density is 2700kg / m 3 , the modulus of elasticity is 70e9Pa, and Poisson's ratio is 0.3. Constraints The left end of the damper plate is fully constrained.

[0066] The constrained damping plate structure described in the present invention is formed by covering the damping material and the constrained layer corresponding to the damping material on an aluminum plate, and a finite element model of the constrained damping plate structure needs to be establishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com