Hollow rotary transformer

A rotary transformer, hollow technology, applied in the direction of transformers, inductors, electrical components, etc., can solve the problems of low energy transfer efficiency and information transfer needs, and achieve the effect of meeting the requirements of the electromagnetic environment, light weight, and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

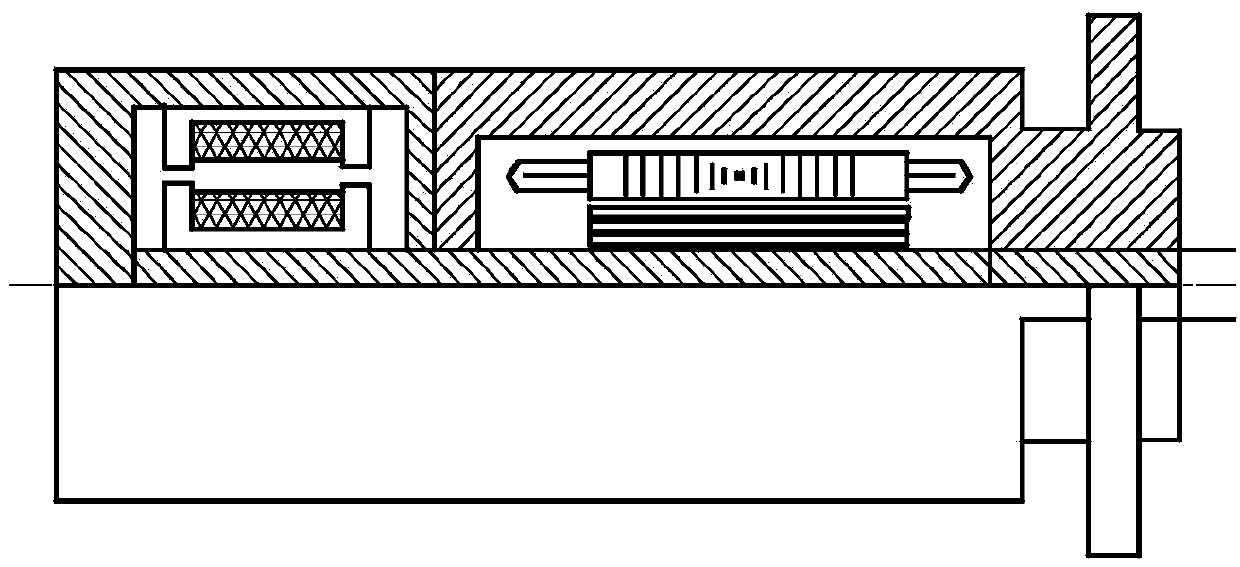

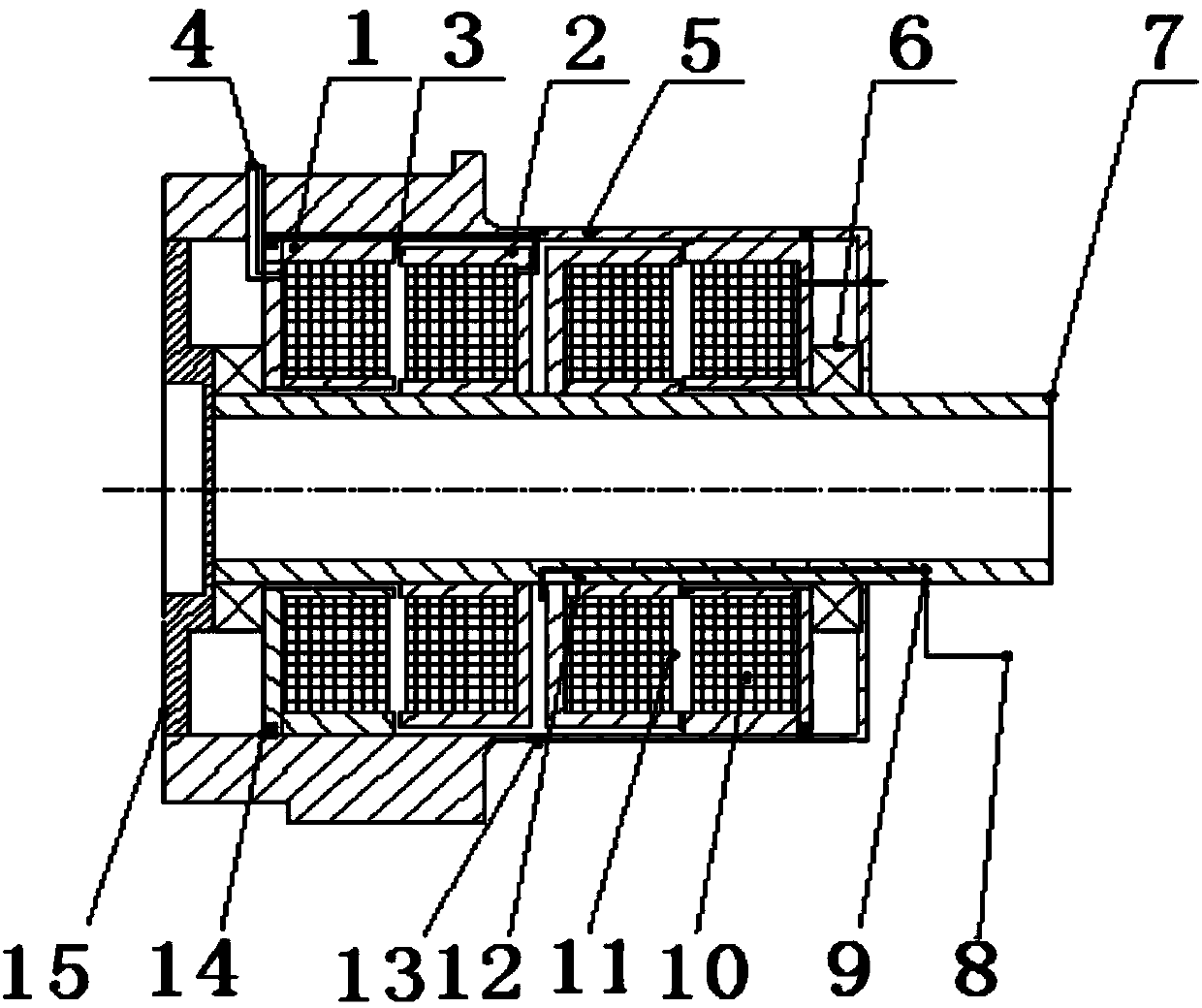

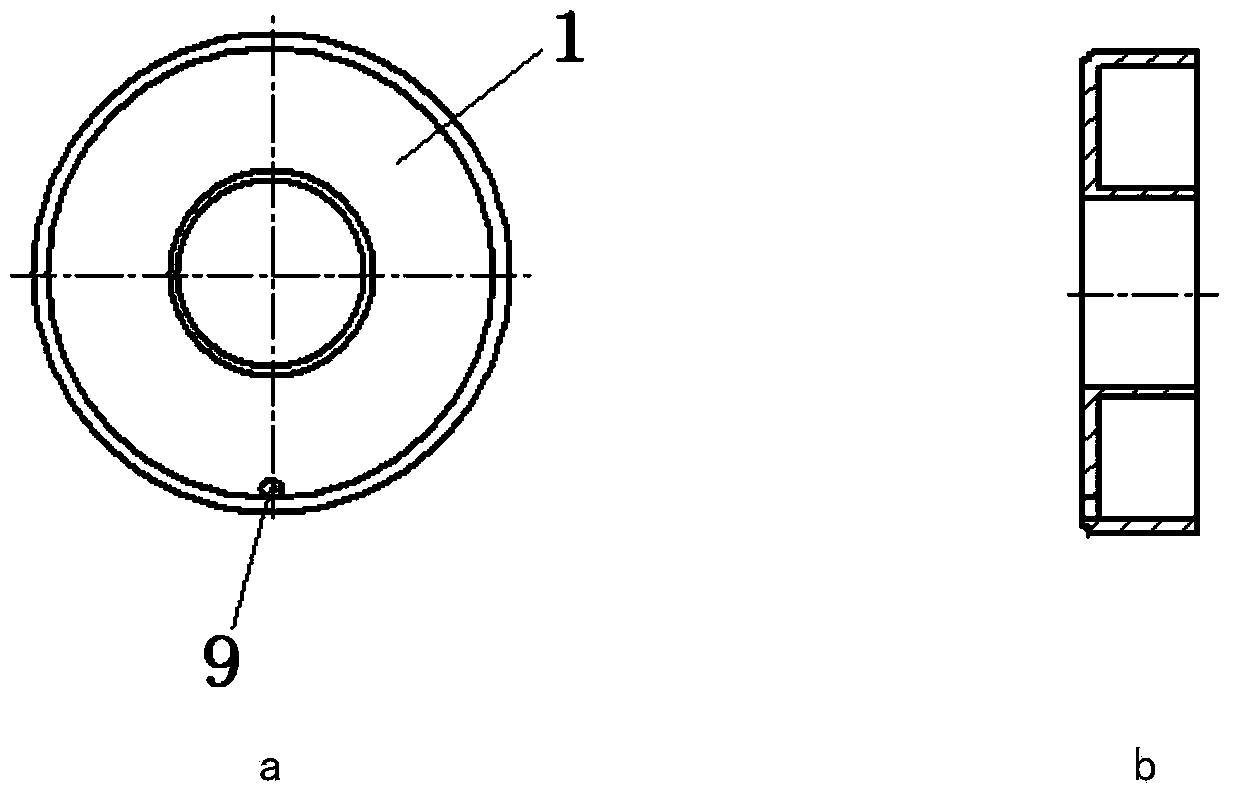

[0041] This embodiment is a hollow rotary transformer, comprising two closed magnetic circuits, a housing 5, a pair of bearings 6, a hollow shaft 7, a stator resistance 10 and a rotor resistance 11, and the closed magnetic circuit is composed of a stator 1 and a rotor resistance 11. A closed magnetic flux channel composed of a rotor 2, and in each closed magnetic circuit, the magnetic gap 3 at the joint between the stator and the rotor is 0.5 mm. Both the stator 1 and the rotor 2 are made of permalloy.

[0042] In this embodiment: a pair of bearings 6 are sleeved on the hollow shaft 7 . The two closed magnetic circuits are sleeved on the hollow shaft 7 and located between the pair of bearings; the stators in the two closed magnetic circuits are in clearance fit with the hollow shaft, and the two closed magnetic circuits The rotor in the magnetic circuit rotates synchronously with this hollow shaft. After the two closed magnetic circuits are fitted on the hollow shaft, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com