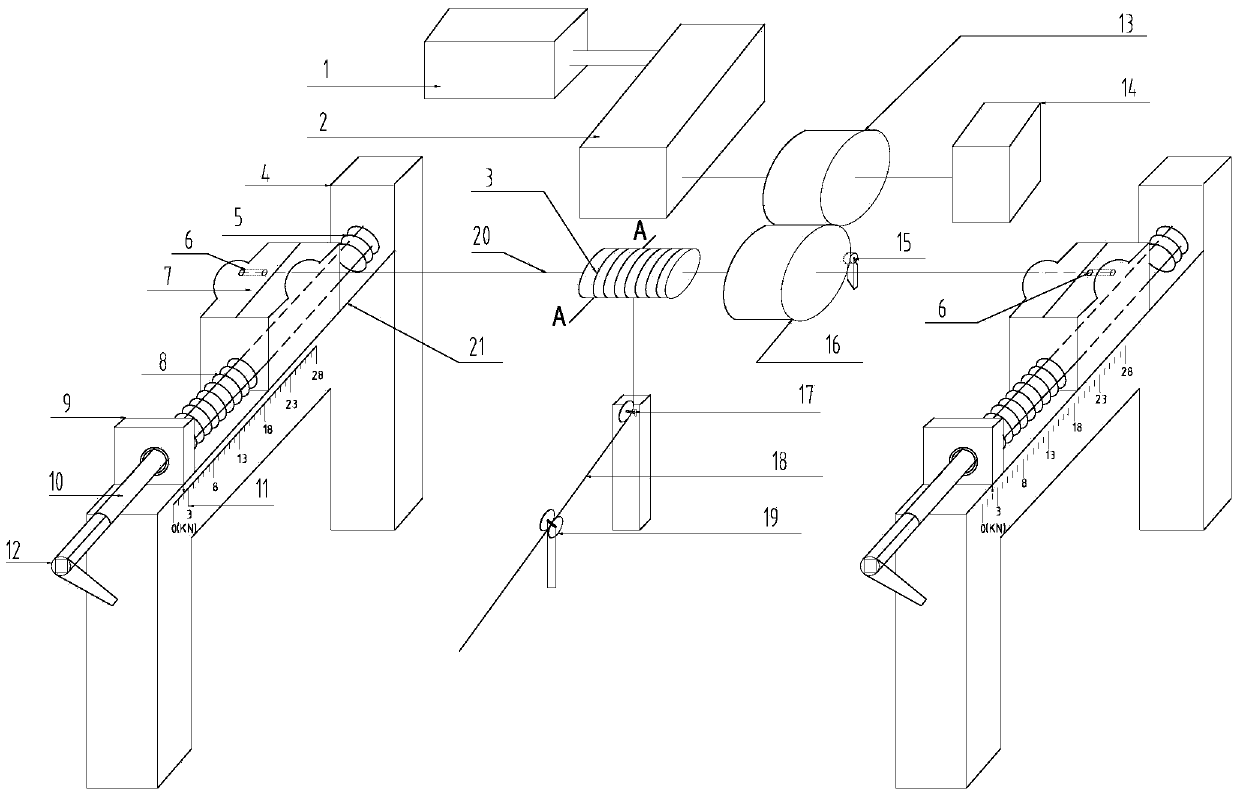

Cable laying traction apparatus

A traction device and cable laying technology, applied in the direction of cable laying equipment, etc., to achieve the effect of improving laying quality, avoiding damage to cables, and preventing damage to cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

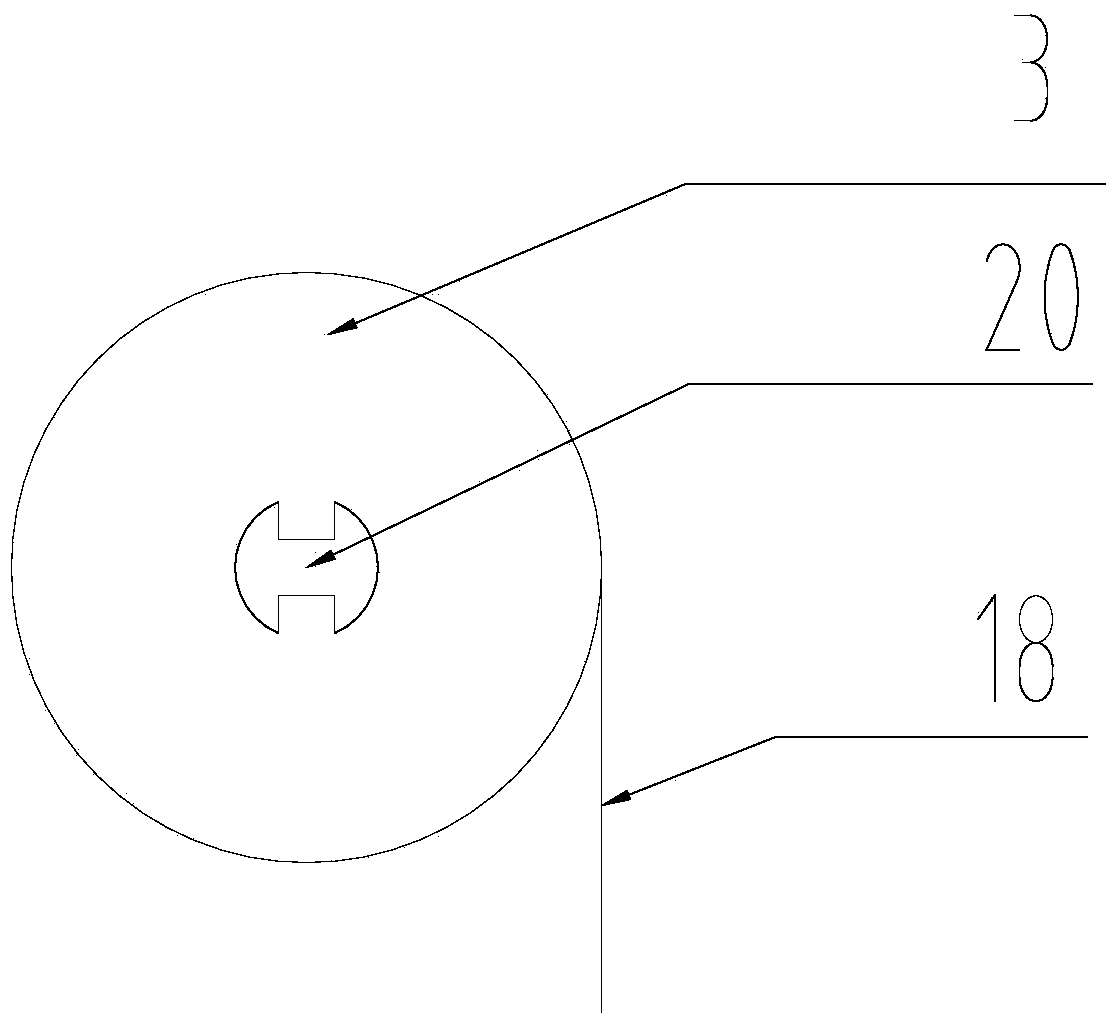

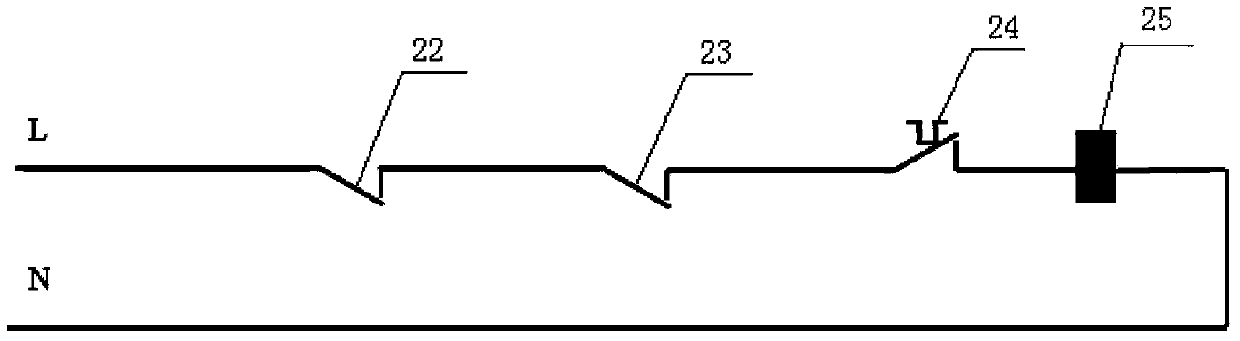

Method used

Image

Examples

specific Embodiment 1

[0037] Specific Example 1: Cable Model: Zryjv22-8.7 / 103 × 120mm 2 , This cable is a copper -core cable with a cross -sectional area of 3 × 120mm 2 If the 3 -phase copper core is trapped at the same time, the cross -sectional area is 360mm 2 The maximum dedestion TMAX = 68ac = 68 × 360 = 24480 Newton.If the two cores are trapped, TMAX = 68ac = 68 × 240 = 16320 Newton.Based on the above calculation value, when the traction model is ZRYJV22-8.7 / 10, the 3 -phase copper core cable is set first, first set the protection movement value of the traction detection device 17 to 24,480 Newton.Then set the maximum catering value of the motion friction wheel 16, and the maximum traction value of the motion friction wheel 16 is slightly less than 24480 Newton. By adjusting the wrench 12 adjustment pressure adjustment of the screw 10At the position of the ruler value.Finally, the device is turned on the cable to launch the traction work.

[0038] If the two -phase copper core cable with the tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com