Process for preparation of highly pure, non-yellowing (meth)acrylic acid

An acrylic acid, high-purity technology, applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of high residual monomer concentration, prolonged initiation period, and no production of acrylic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

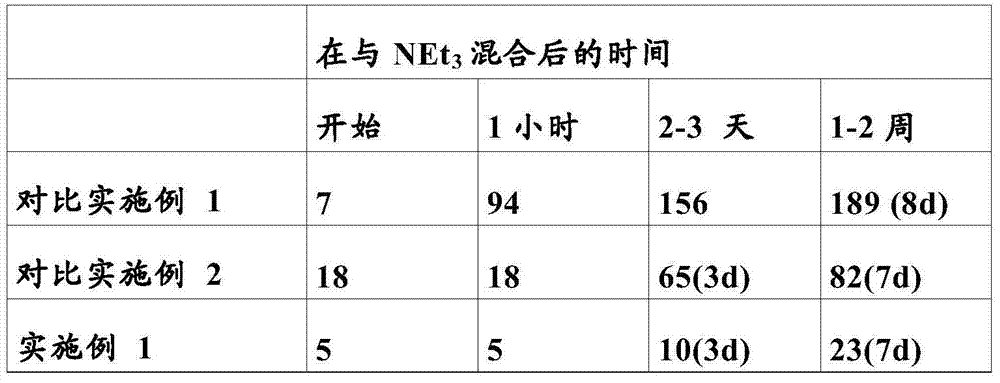

Examples

Embodiment 1

[0051] This example was carried out analogously to comparative example 2, except that, instead of filtration after the ion exchange treatment, distillation was carried out according to method step e).

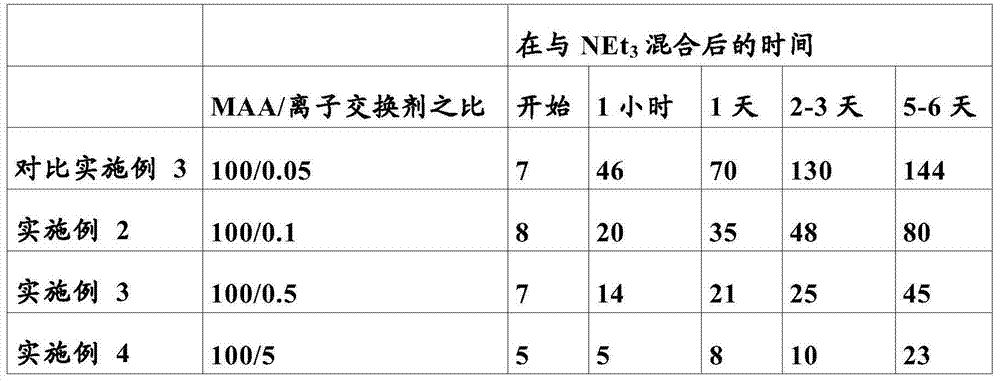

Embodiment 2-4

[0055] These examples were carried out according to Example 1, however, with different ratios of methacrylic acid to ion exchanger as shown in Table 2.

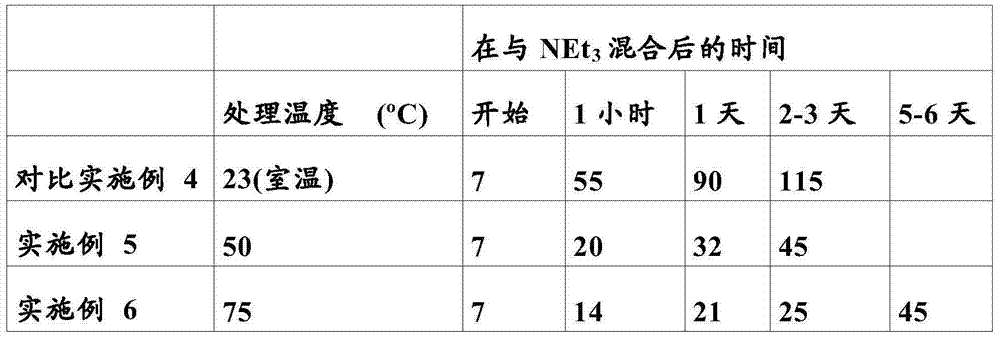

Embodiment 5-6

[0059] These examples were carried out according to Example 1, however, with the ion exchange treatment temperatures indicated in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com