Curable epoxy resin composition

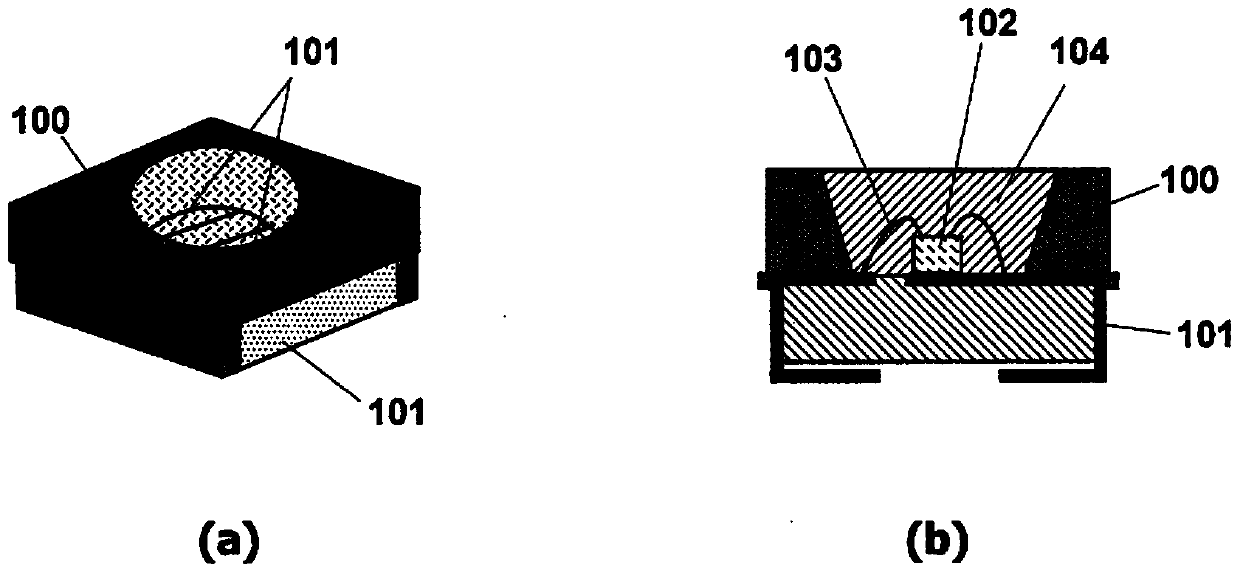

A technology of epoxy resin and epoxy compound, which is applied in the direction of electrical solid devices, semiconductor/solid device parts, electrical components, etc., can solve the problems of cracks in packaging materials and packaging materials, and achieve the effect of excellent resistance to moisture absorption and reflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0170] (manufacture of rubber particles)

[0171] 500 g of ion-exchanged water and 0.68 g of sodium dioctyl sulfosuccinate were placed in a 1 L polymerization vessel equipped with a reflux condenser, and the temperature was raised to 80° C. while stirring under a nitrogen stream. A monomer mixture consisting of 9.5 g of butyl acrylate, 2.57 g of styrene, and 0.39 g of divinylbenzene corresponding to about 5% by weight of the amount required to form the core portion was added together, and stirred for 20 minutes to emulsify Then, 9.5 mg of potassium peroxodisulfate was added, and the mixture was stirred for 1 hour to conduct initial seed polymerization. Next, 180.5 mg of potassium peroxodisulfate was added, followed by stirring for 5 minutes. The remainder (about 95% by weight) of 180.5 g of butyl acrylate, 48.89 g of styrene, A monomer mixture comprising 7.33 g of divinylbenzene was subjected to the second seed polymerization, and then aged for 1 hour to obtain a core portio...

manufacture example 2

[0176] (Manufacture of rubber particle dispersed epoxy compound)

[0177] 10 parts by weight of the rubber particles obtained in Production Example 1 were dispersed in a product name "Celloxide 2021P" (3,4-epoxy ring 70 parts by weight of hexylmethyl (3,4-epoxy) cyclohexane carboxylate, manufactured by Daicel, was vacuum defoamed to obtain a rubber particle-dispersed epoxy compound (viscosity at 25° C.: 724 mPa·s ).

[0178] In addition, the viscosity (viscosity at 25° C.) of the rubber particle-dispersed epoxy compound obtained in Production Example 2 (a product obtained by dispersing 10 parts by weight of rubber particles in 70 parts by weight of Celloxide 2021P) was measured using a digital viscometer. (trade name "DVU-EII type", manufactured by Tokimec Co., Ltd.).

manufacture example 3

[0180] (manufacture of epoxy resin)

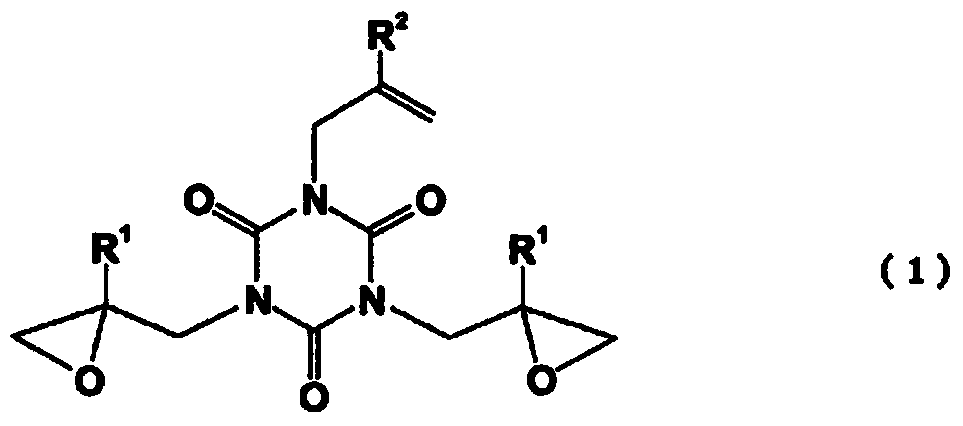

[0181] With the compounding ratio (unit: weight part) shown in Table 1, Table 2, trade name "Celloxide 2021P" (alicyclic epoxy compound, manufactured by Daicel Co., Ltd.), monoallyl diglycidyl isocyanurate (MA-DGIC, Shikoku Chemical Industry Co., Ltd.), trade name "X-40-2678" (siloxane derivative having two epoxy groups in the molecule, manufactured by Shin-Etsu Chemical Co., Ltd.), trade name " X-40-2720" (siloxane derivatives having three epoxy groups in the molecule, manufactured by Shin-Etsu Chemical Co., Ltd.), trade name "X-40-2670" (siloxane derivatives having four epoxy groups in the molecule Silicone derivative, manufactured by Shin-Etsu Chemical Co., Ltd.), trade name "YD-128" (bisphenol A type epoxy resin, manufactured by Nippon Steel Chemical Co., Ltd.), dispersed rubber obtained in Production Example 2 The epoxy resin of the particles was uniformly mixed using a rotation and revolution type stirring device (manufactured by Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com