Method of fabrication of micro-optics device with curved surface defects

A manufacturing method and technology for curved surfaces, applied in optical elements, photoengraving process of pattern surface, optics, etc., can solve the problem of SPL probe being in the development stage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The description below is structured as follows:

[0059] I. Introduction

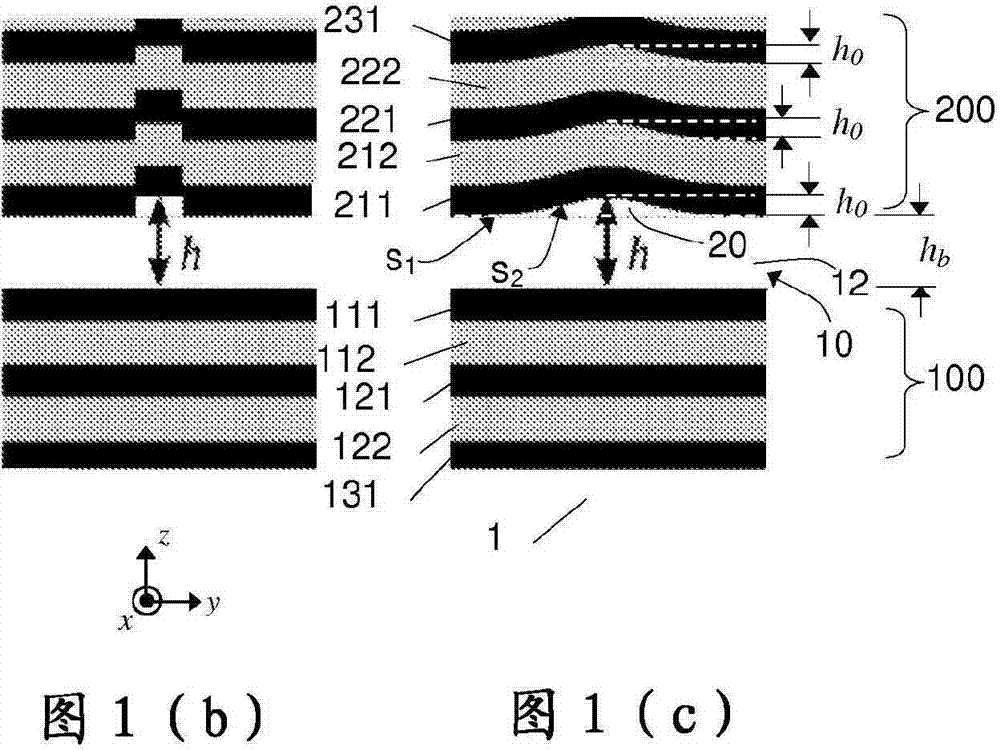

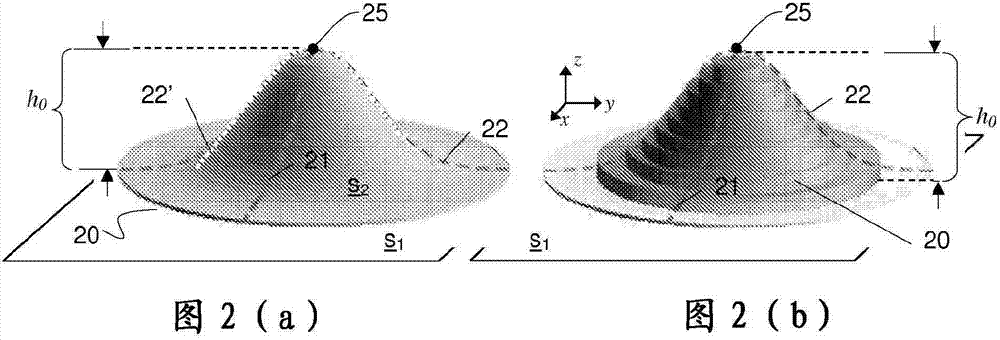

[0060] II. Description of Vertical Microcavity

[0061] III. Manufacturing method

[0062] IV. Final Considerations

[0063] I. Introduction

[0064] The present invention uses novel nanopatterning techniques to accurately pattern "defects" embedded in micro-optical devices such as microcavities. Defects can be given a specific, precise and smooth profile (or shape) that allows increased interaction with electromagnetic waves, eg for electromagnetic wave confinement applications. Furthermore, embedded defects can have well-controlled curvatures (eg, faithful Gaussian shapes) at adjacent vertices, leading to unprecedented constraint properties. Such curved defect shapes are not achievable with existing techniques such as evaporation or planar etching. The fabrication method considered here involves a modified SPL technique in which polymer chains are desorbed or unchained to a fine particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com