Disassembly and assembly structure for furniture drawer front panel

A front panel and drawer technology, which is applied to drawers, furniture parts, household appliances, etc., can solve the problems of inconvenient daily use of drawer panels, inconvenient use by users, and unsatisfactory users, and reduce assembly steps. And the effect of manufacturing tolerance, quick disassembly and assembly, great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

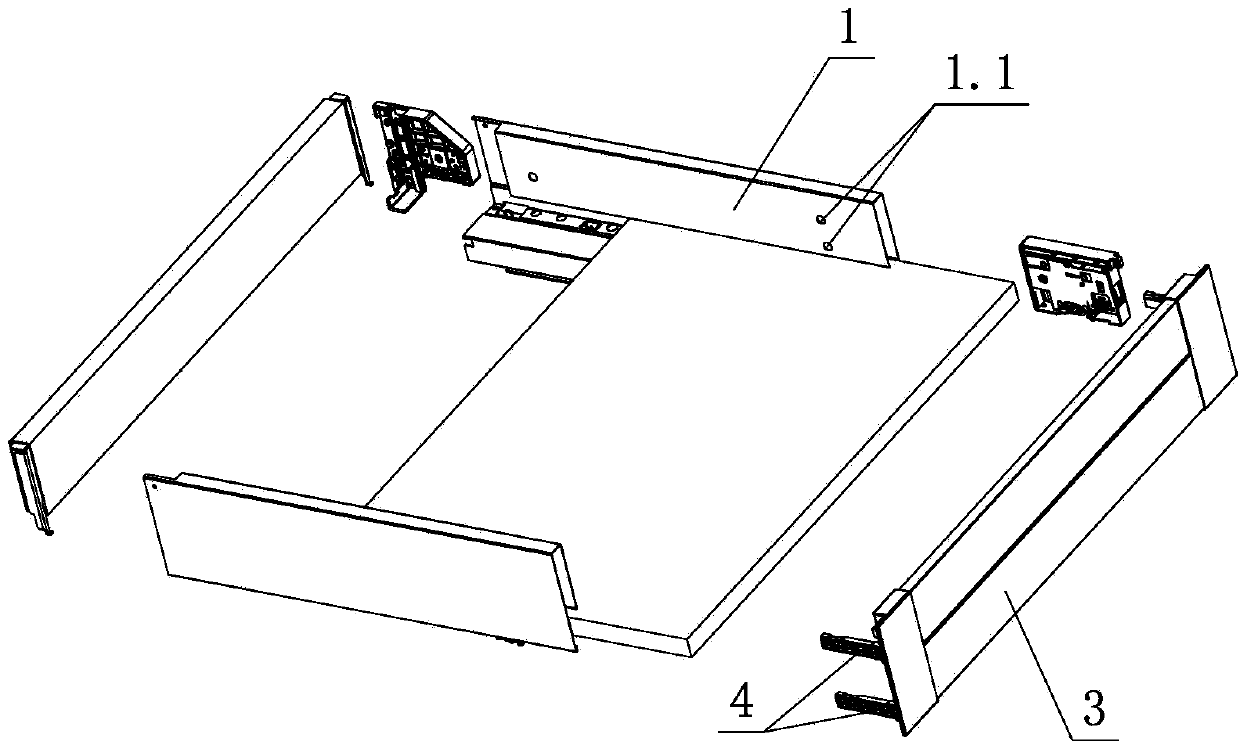

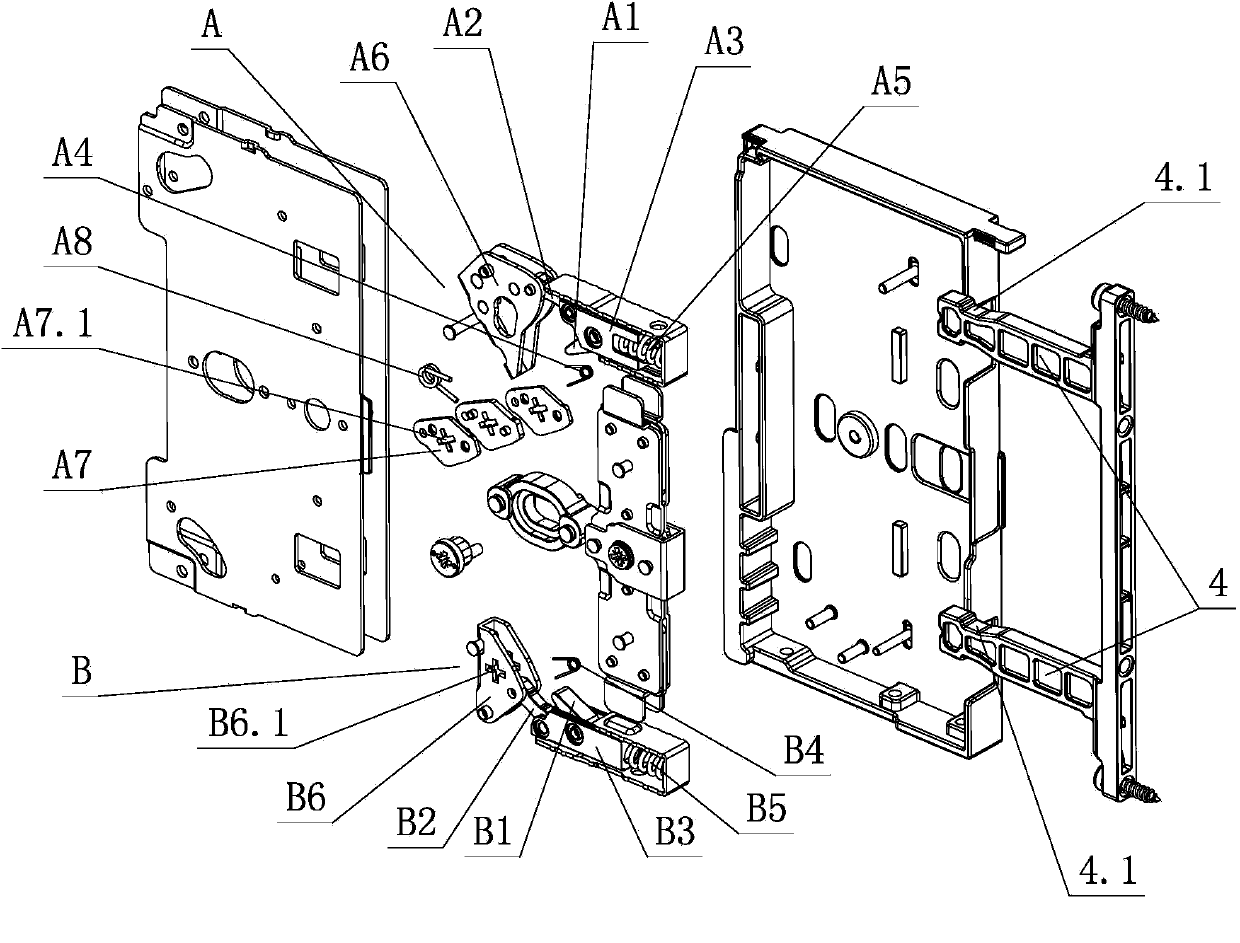

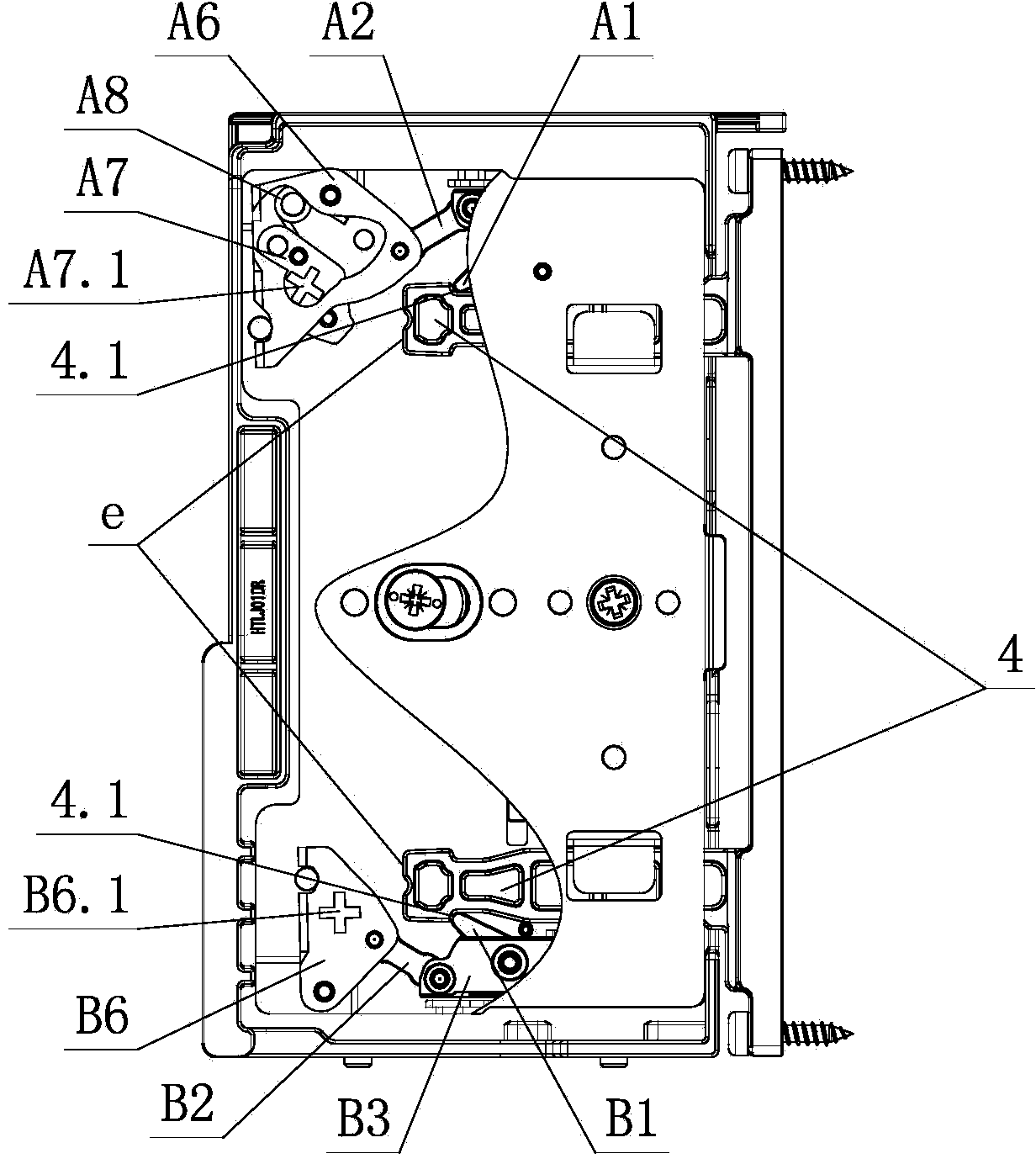

[0026] see Figure 1-Figure 14, the disassembly and assembly structure of the front panel of the furniture drawer includes a fixing device arranged on the side panel 1, the front panel 3 is connected with the fixing device through more than two connecting elements 4, and more than two sets of locking devices are arranged on the fixing device. Locking and separating the lock-off mechanism of the connecting element 4, the two or more sets of lock-off mechanisms are relatively independent up and down; wherein, at least one set of the first lock-off mechanism A and the connecting element 4 are unlocked and / or after unlocking, The front and rear positions of the connecting element 4 on the first lock-off mechanism A remain basically unchanged, or can move within the effective range d and are no longer locked; when the second lock-off mechanism B and the connecting element 4 are unlocked, the second lock-off mechanism B The push-out element B6 of the mechanism B pushes the connectin...

no. 2 example

[0043] see Figure 15 , Figure 16 , the dismounting structure of the front panel of the furniture drawer is different from the first embodiment in that: the fixing device is provided with a release element 2, and the release element 2 is provided with a release function part 2.1 for a tool, and the release element 2 Respectively through the interlocking element 5 and / or the ejection element 6, it is drivingly connected with the holding element A7 and the ejection element B6, and acts on the release part 2.1 of the release element 2 through a tool, and is driven and held by the interlocking element 5 and / or the ejection element 6 The element A7 and the push-out element B6 swing, and the connecting element 4 is unlocked synchronously with the first lock-off mechanism A and the second lock-off mechanism B through the release part 2.1.

[0044] Others are not described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com