Activated carbon jetting device

A technology of injection device and activated carbon, which is applied in the direction of injection device, injection device, dispersed particle separation, etc., can solve the problems that activated carbon cannot completely cover the flue, the diffusion effect of the direct injection port is not very good, and dioxin enters the external air, etc. Achieve the effect of small resistance, reduce resistance and protect the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

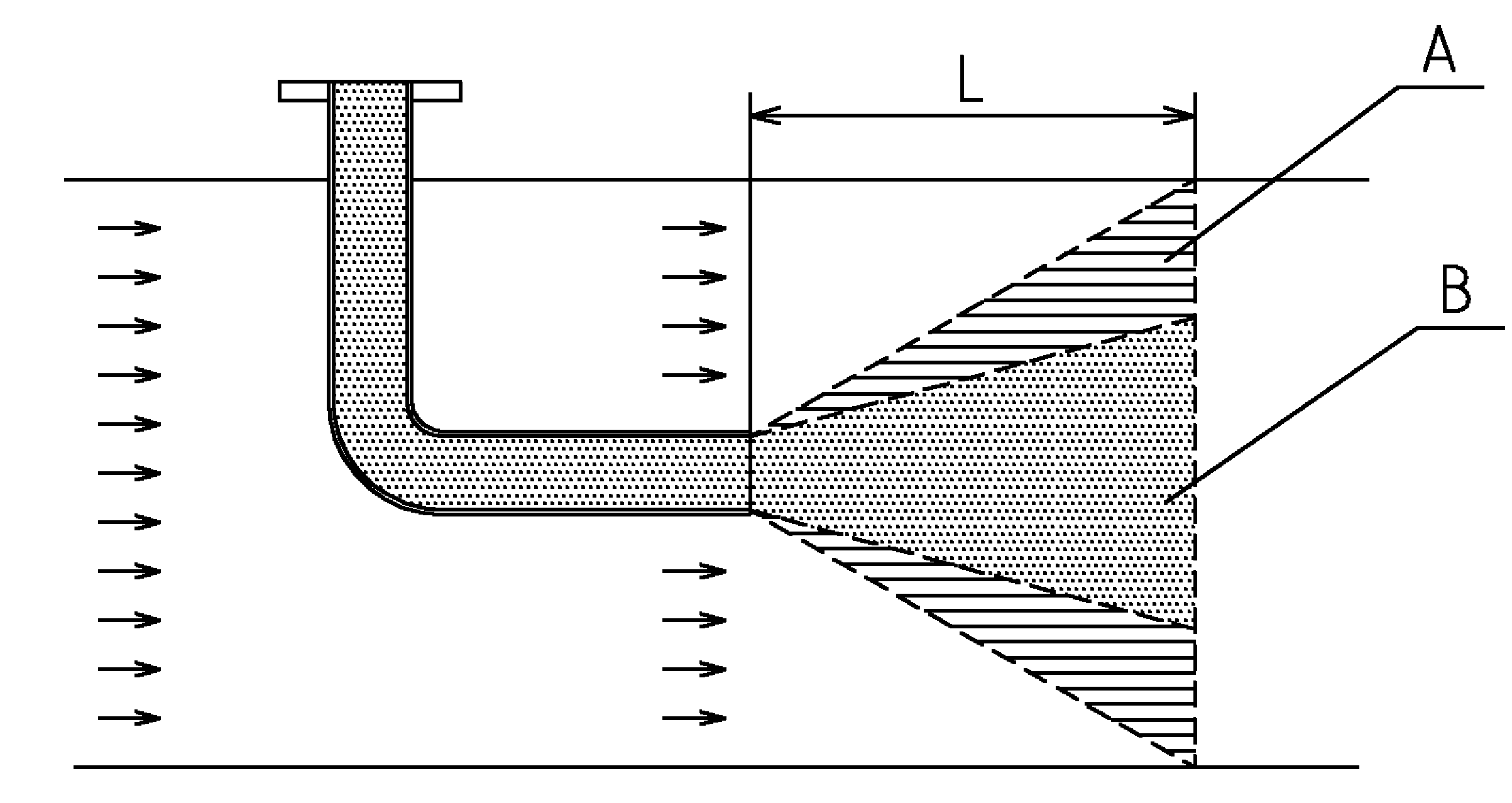

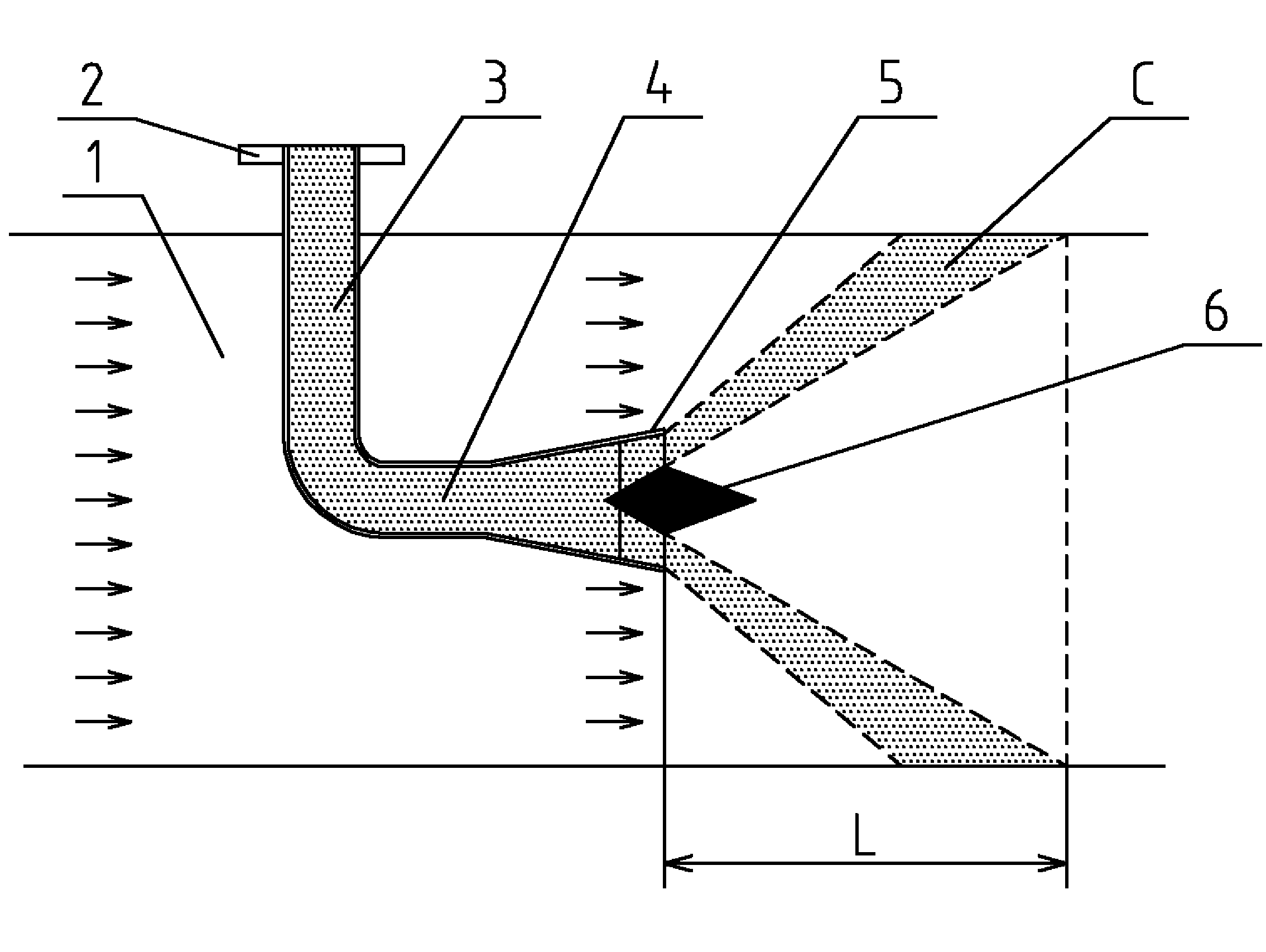

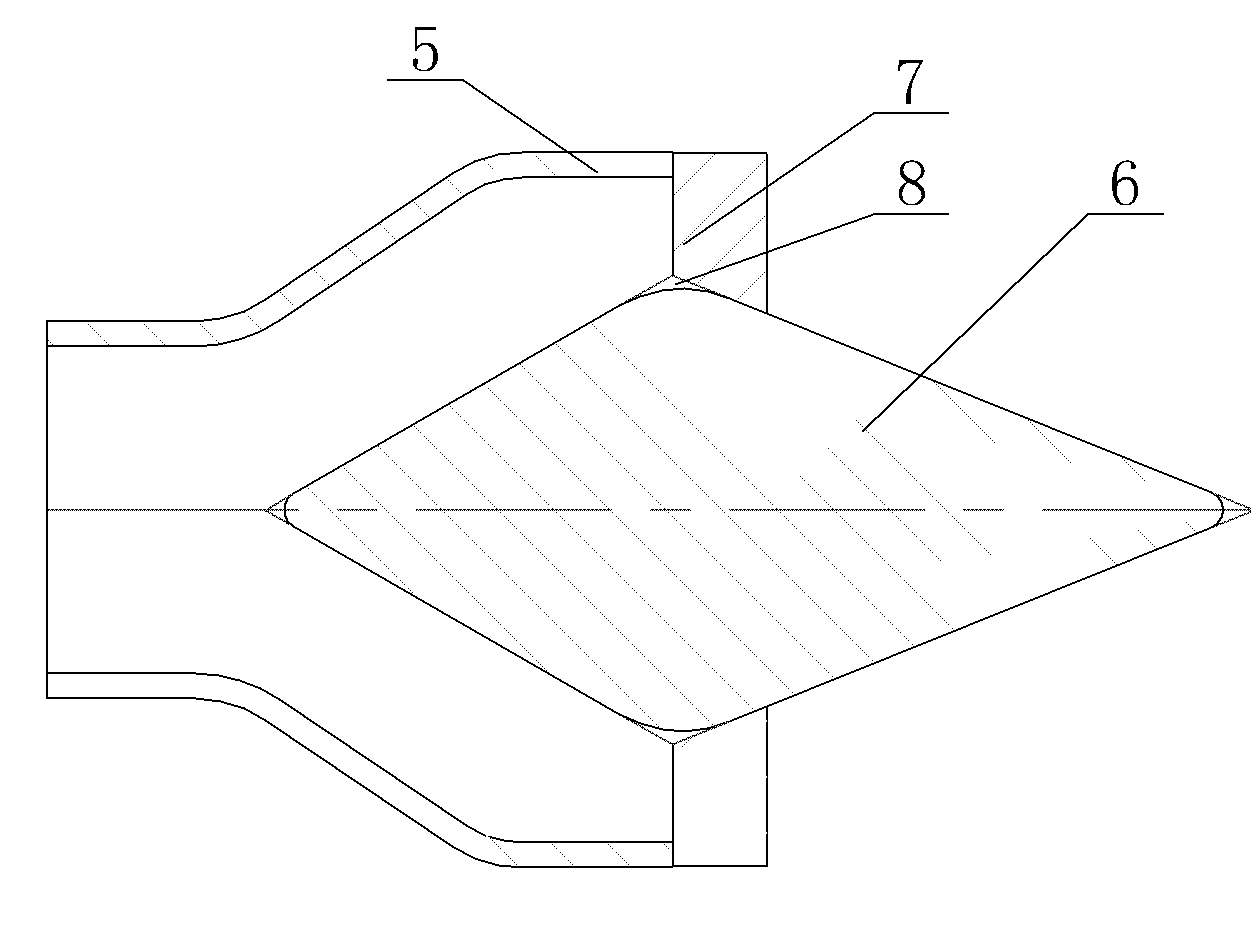

[0017] An activated carbon injection device, see Figure 2 ~ Figure 4 : It includes a flue 1, in which flue gas circulates, an activated carbon injection pipe is arranged in the flue 1, and the flue gas is exhausted from front to back along the flue 1, and the activated carbon injection pipe It includes a feed port 2, a vertical connecting pipe 3, and a horizontal outlet pipe 4 exposed at the upper end of the pipe. The outlet 5 of the horizontal outlet pipe 4 is a flared trumpet shape. The inlet of the oriented outlet pipe 4 is connected to the lower outlet of the vertical connecting pipe 3, the horizontal outlet pipe 4 is arranged along the direction of flue gas outlet, and the outlet 5 of the horizontal outlet pipe 4 is arranged with increasing For the speed cone 6, the front end of the speed increasing cone 6 is a cone structure, and the cone structure is a cone that flares from front to back.

[0018] The rear end portion of the speed increasing cone 6 is a tapered structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com