Automatic blowing machine before casting

A purging machine and automatic technology, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of reducing yield, increasing cost, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

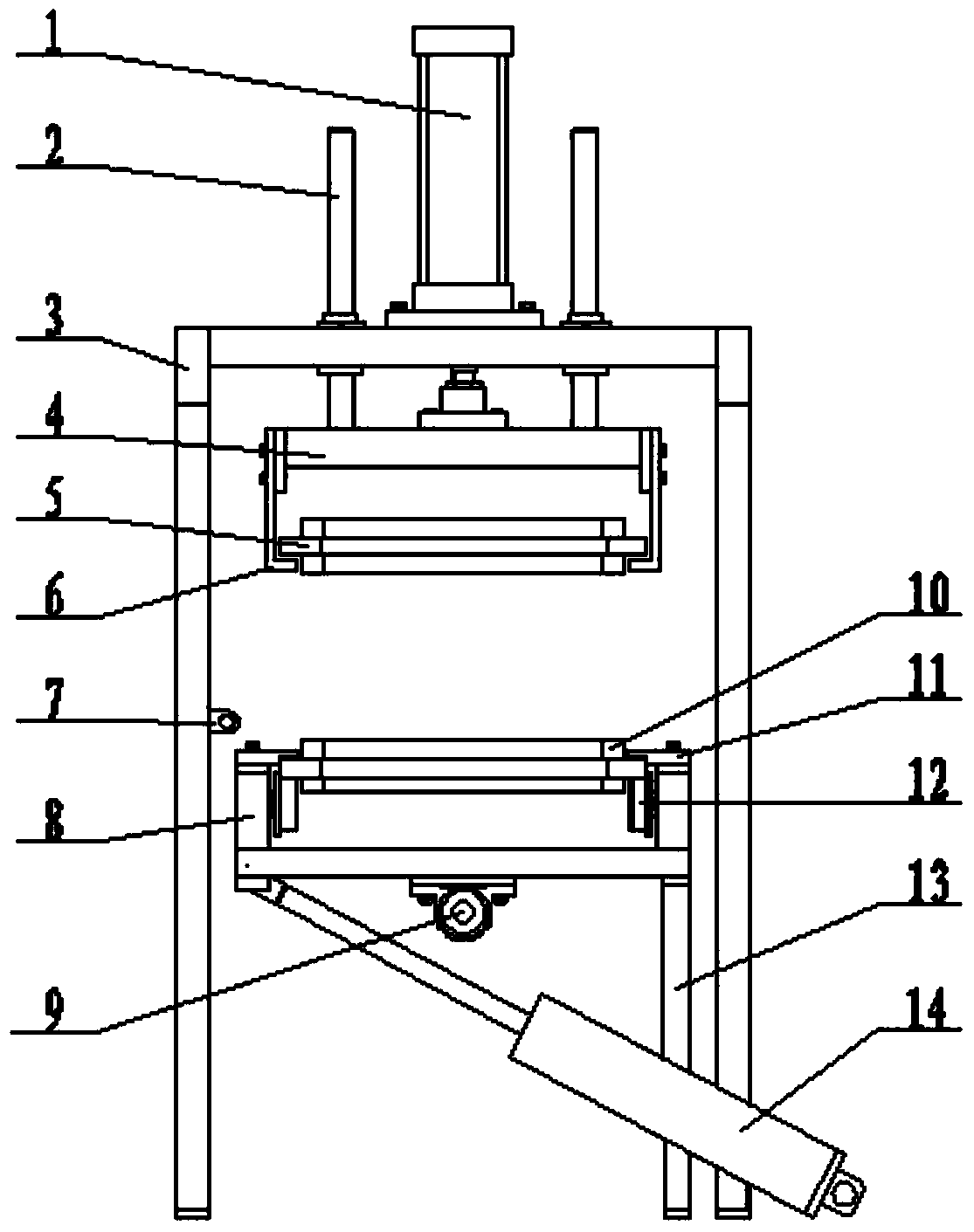

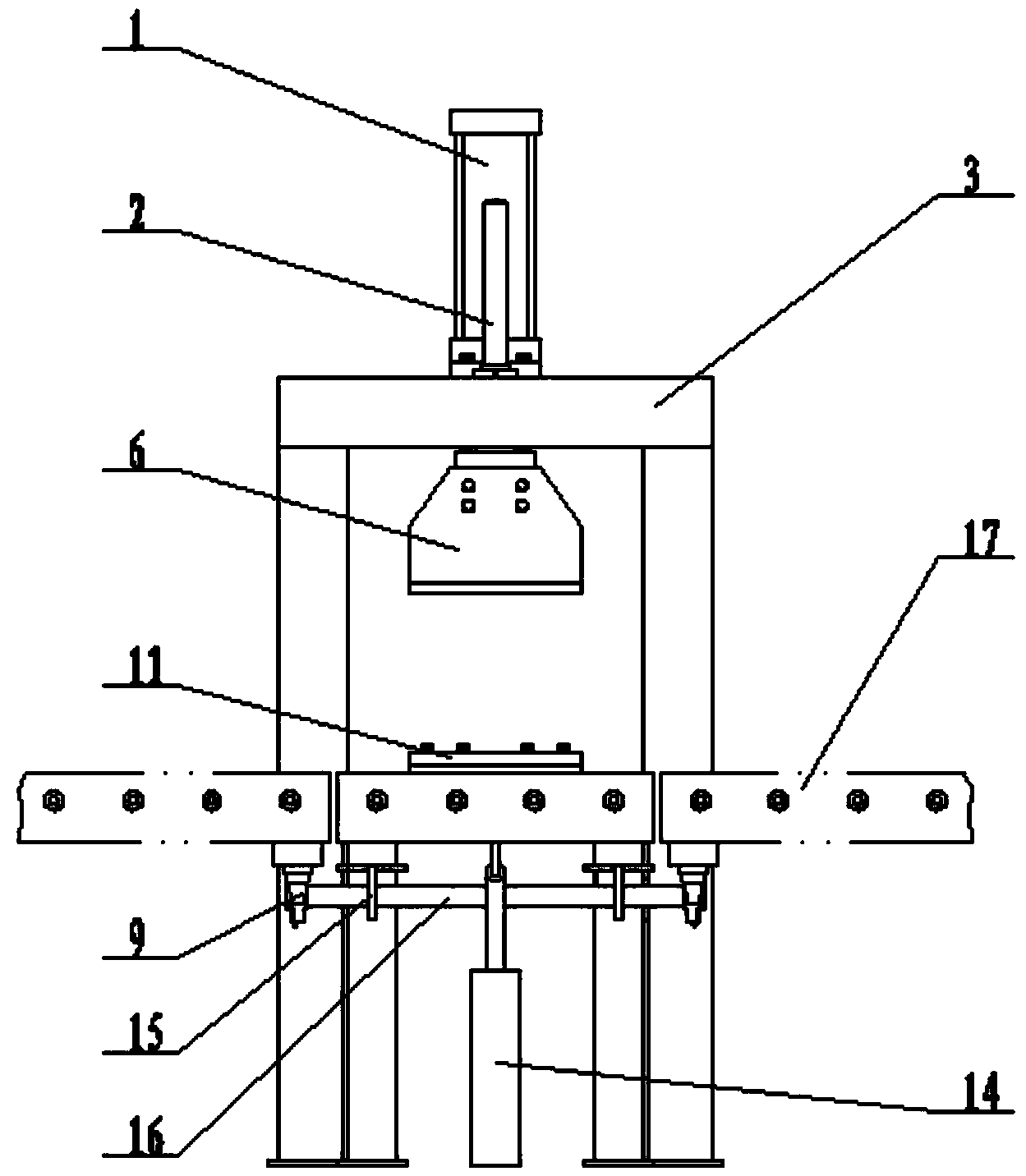

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

[0017] like figure 1 and figure 2 In the shown automatic purging machine before pouring, the lifting cylinder 1 is fixedly installed on the frame 3 through the end flange, and its lower end is fixedly connected with the lifting seat 4, and the guide rod and guide sleeve 2 pass through the frame 3 The hole of the lifting seat 4 is fixedly connected with the lifting seat 4, and the two ends of the lifting seat 4 are respectively fixed with grab hooks 6, and the grab hooks 6 support the mold upper mold 5; the flip support 15 is fixedly installed on the roller support 13, and the roller support 13 Installed at the lower end of the frame 3, the mold limiter 11 is movably installed above the roller frame 8. When the blower is working, the mold lower mold 10 is fixed to ensure that the mold lower mold 10 will not be displaced or slide. The overturn shaft seat 9 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com