Welding method of high temperature and high pressure bellows globe valve

A corrugated pipe stop valve and welding method technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high fatigue resistance, affecting the fatigue resistance of weld seams, fast heat conduction, etc., and achieve the improvement of elastic fatigue strength and service life, preventing the generation of local fine oxides, ensuring the effect of quality and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

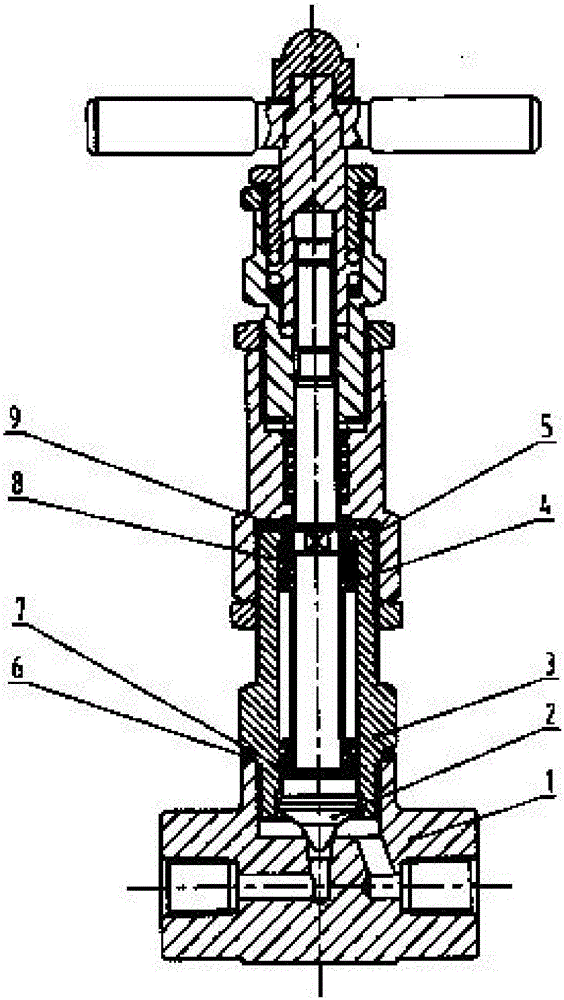

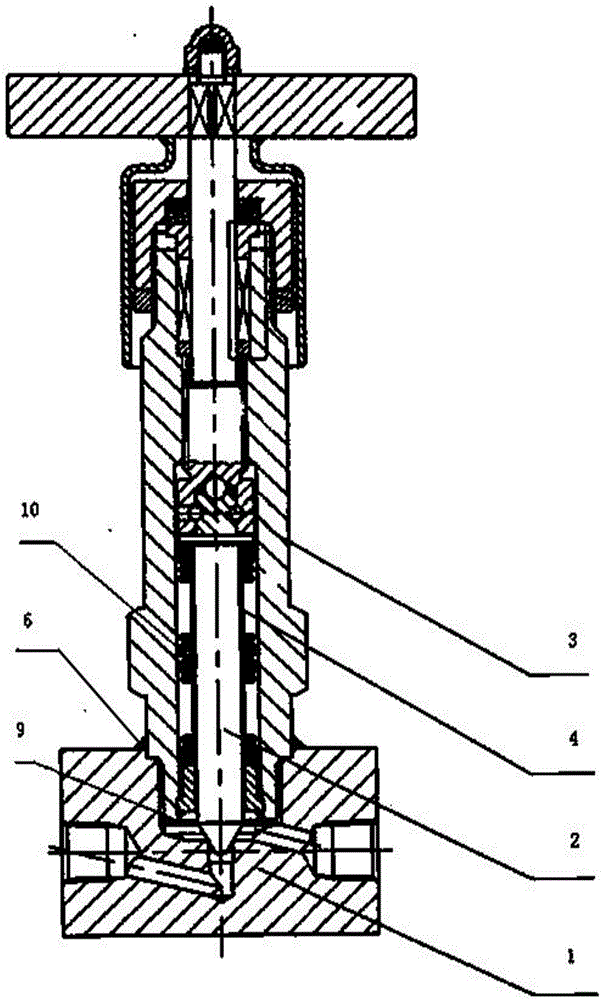

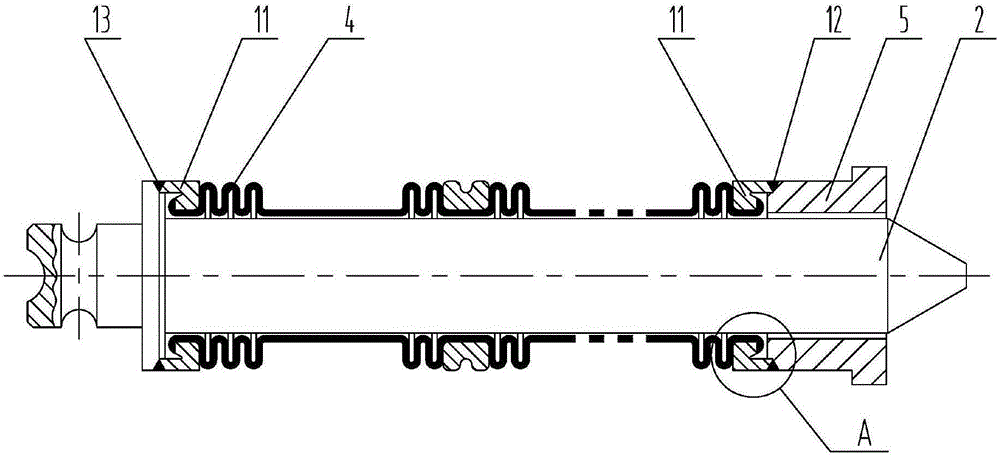

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] 1. A welding method for a high-temperature and high-pressure corrugated pipe stop valve, which consists of a DC argon arc welding machine, a circular seam automatic welding machine, an Ar gas cylinder, a regulating valve, a pressure gauge, a glass rotameter, a soft rubber hose, an electromagnetic reversing valve, Composed of pipe joints, solder, etc., characterized in that: DC argon arc welding machine and circular seam automatic welding machine are connected well, regulating valve, pressure gauge, glass rotameter and soft rubber tube are installed on the Ar gas cylinder; the soft rubber tube is divided into A , B two roads, A road is the Ar shielding gas pipe directly connected to the DC argon arc welding machine; B road is the back shielding gas pipe connected to another regulating valve and glass rotameter, and then connected to the welding mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com