Automatic surface grinding machine working table cleaning method and device

A work surface and automatic cleaning technology, applied in the direction of cleaning method using gas flow, cleaning method and utensils, cleaning method using liquid, etc., can solve the problem of increasing the labor intensity and technical difficulty of the operator, without automatic cleaning of the work surface, workers Inconvenient operation and other problems, to achieve the effect of ensuring consistency, high cleanliness, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

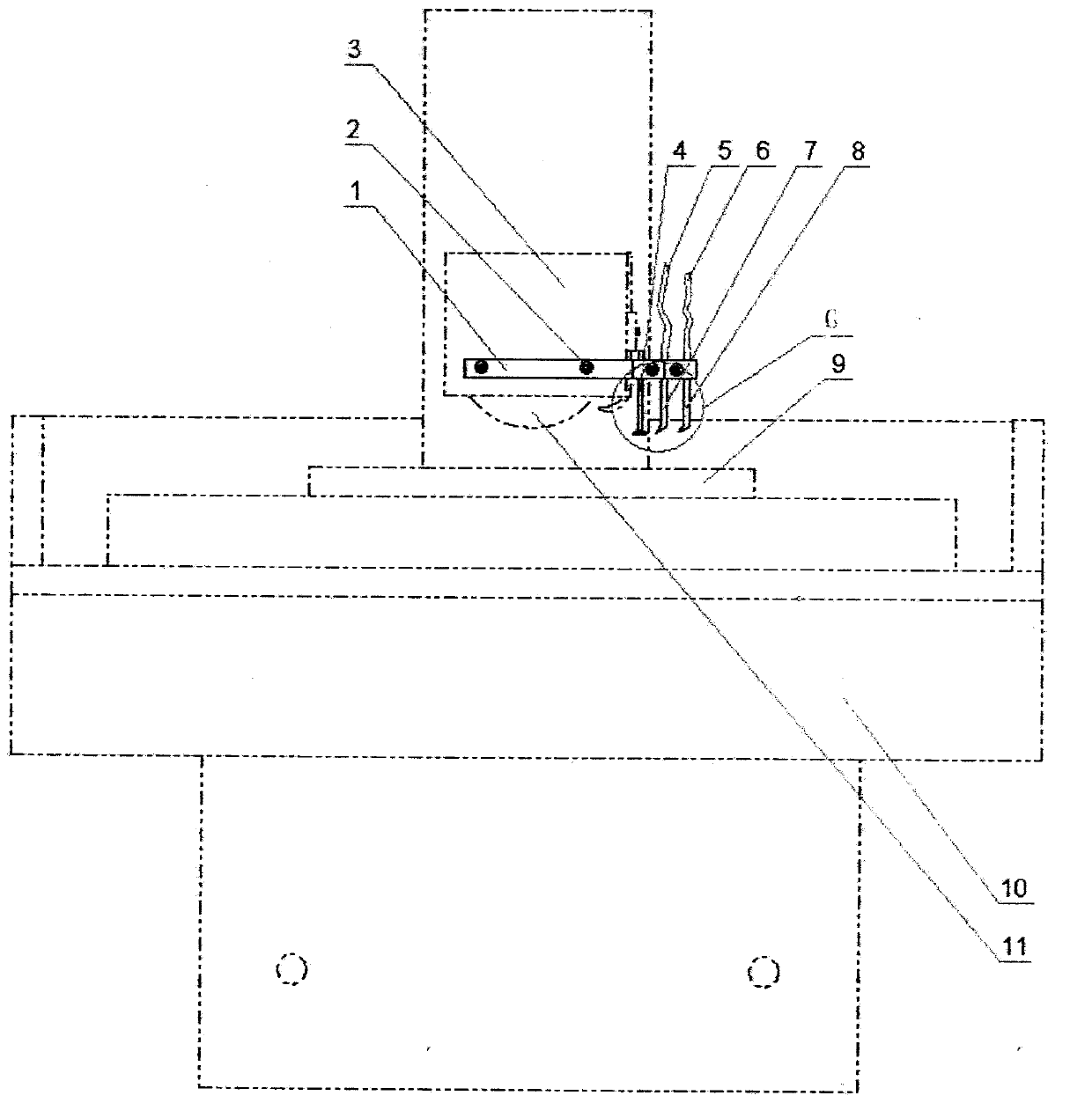

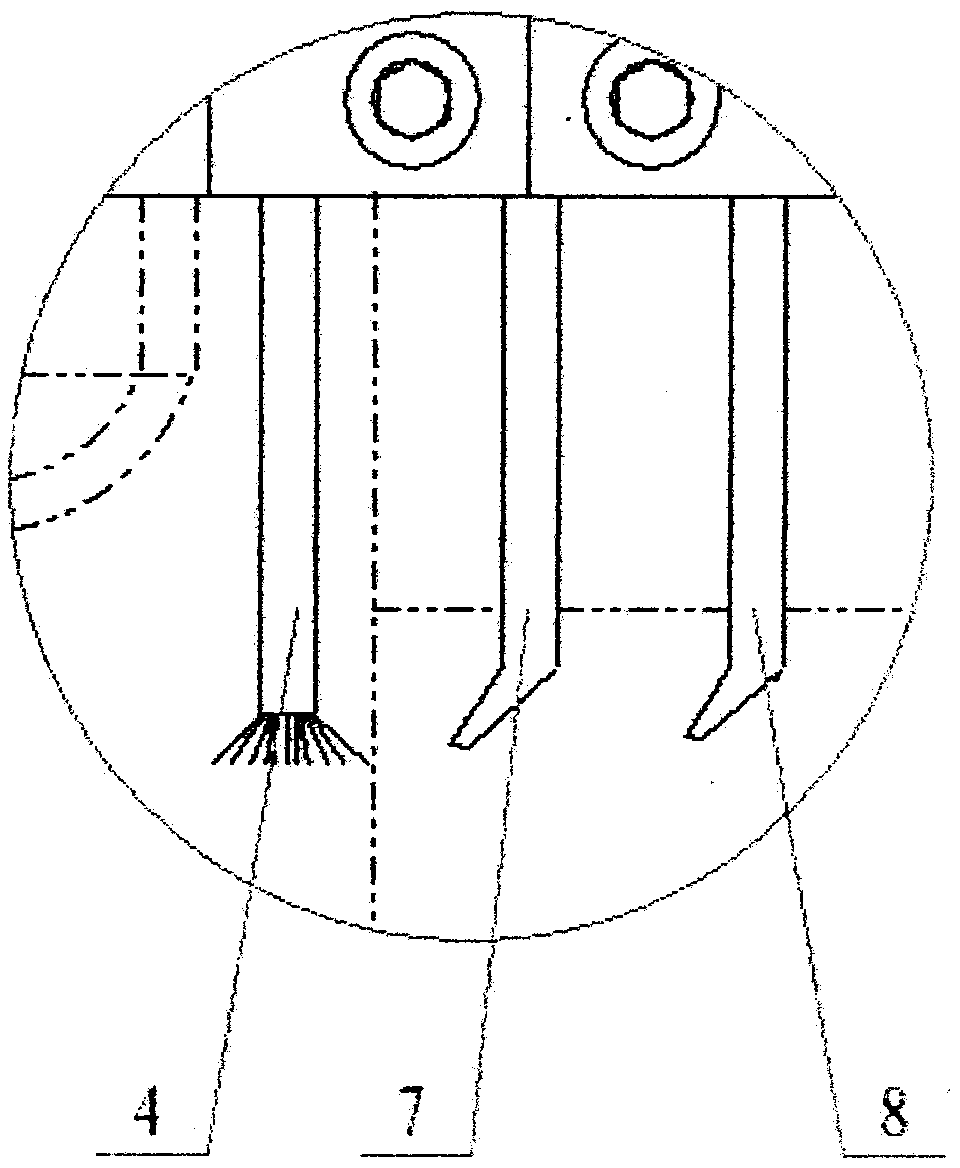

[0011] From figure 1 , figure 2 It can be seen that the fixing clip 1 is fixed on the grinding wheel cover 3 of the grinding machine 10 with the hexagon socket head cap screw 2, and the cleaner 4, the booster water nozzle 7, and the booster gas nozzle 8 are respectively fixed on the side of the fixing clip 1 with the hexagon socket head cap screw 2. In each tank, one end of the pressurized water pipe 5 is connected to the upper part of the pressurized water nozzle 7, the other end is connected to the outlet of the centralized filtered circulating water booster electric pump, and one end of the compressed air delivery pipe 6 is connected to the top of the pressurized air nozzle 8. The upper part is connected, and the other end is connected to the interface of the compressed air station.

[0012] During work, through the programming input of the control panel of the CNC surface grinder 10, after the grinding wheel 11 has processed the workpiece, the table top of the grinder wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com