Novel stainless steel cut tobacco transfer box

A stainless steel, turnover box technology, applied in rigid containers, containers, packaging and other directions, can solve the problems of the box body is not easy to dry, the tobacco in the box is deteriorated, and the box body is troublesome to clean, etc., to achieve the effect of easy cleaning, not easy to deform, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

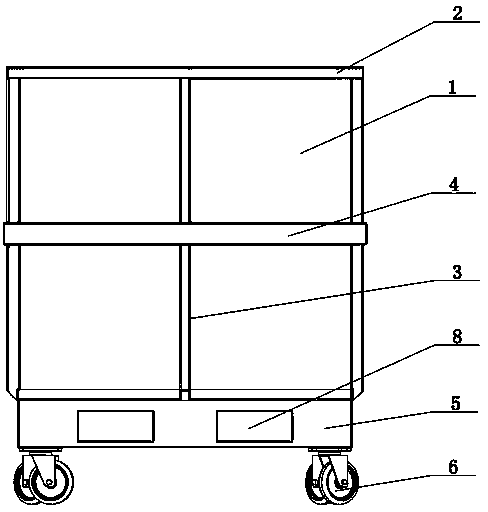

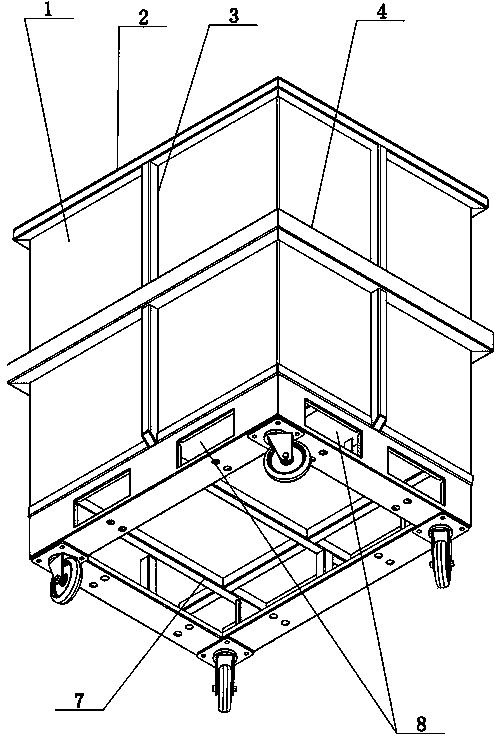

[0013] refer to figure 1 and figure 2 , the specific embodiment adopts the following technical solutions: it includes a stainless steel box body 1, a box mouth reinforcement rib 2, a steel plate reinforcement rib 3, a box turning reinforcement rib 4, a bottom tray 5, a universal wheel 6, a box bottom reinforcement rib 7, a forklift fork Holes 8; the stainless steel box 1 is set on the tray 5 at the bottom of the box, the top of the stainless steel box 1 is provided with a box mouth reinforcement 2, the side wall of the stainless steel box 1 is provided with a steel plate reinforcement 3 in a vertical direction, and the stainless steel box 1 The middle part of the outer wall is provided with transverse turning ribs 4, the bottom of the box bottom tray 5 is provided with box bottom ribs 7, the four corners of the box bottom tray 5 are provided with universal wheels 6, and the box bottom tray 5 is provided with forklift fork holes 8 around.

[0014] The four corners in the stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com