Load controller for elevator and frequency converter for elevator

A technology of load controller and frequency converter, applied in the field of elevators, can solve the problems of noise and arc drawing, and achieve the effect of eliminating noise and arc drawing, reducing cost, and improving reliability and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

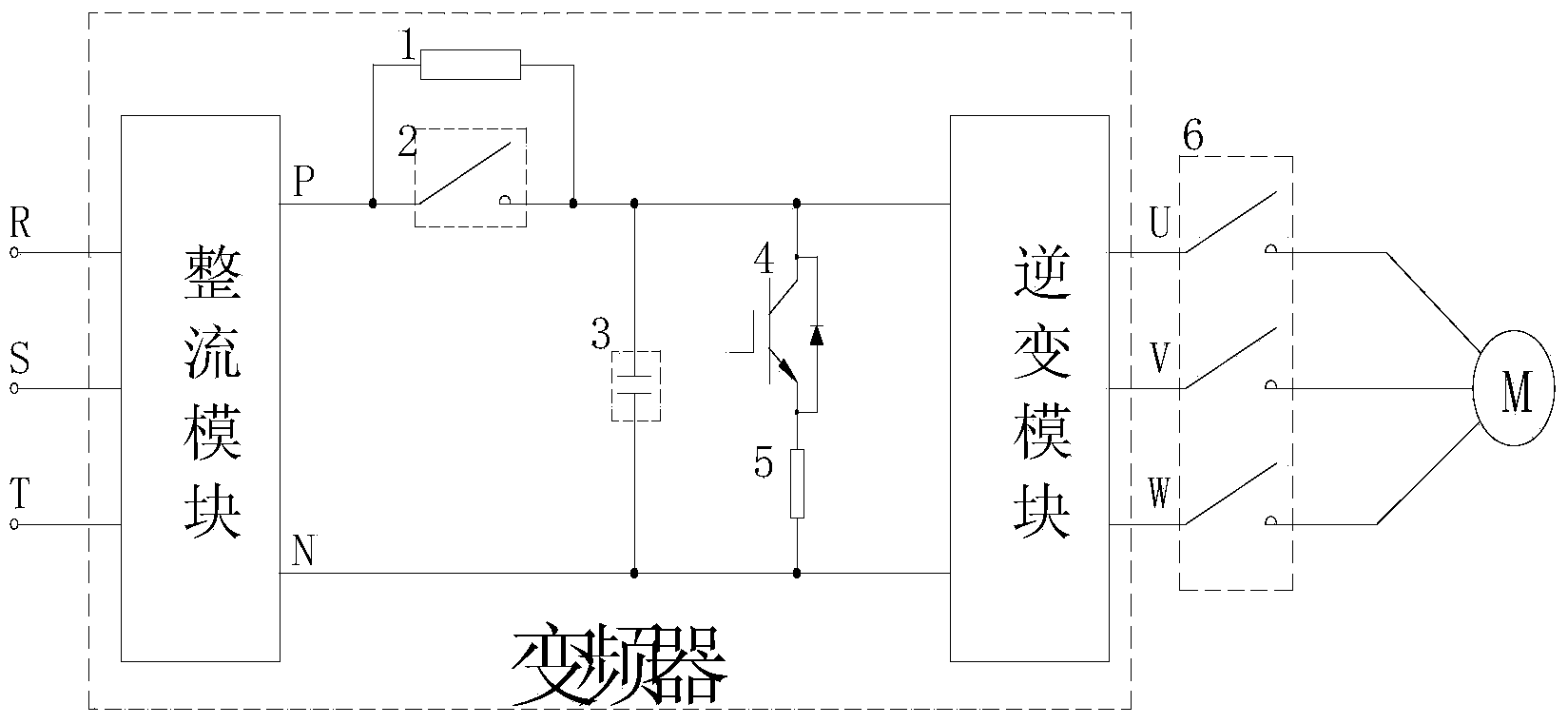

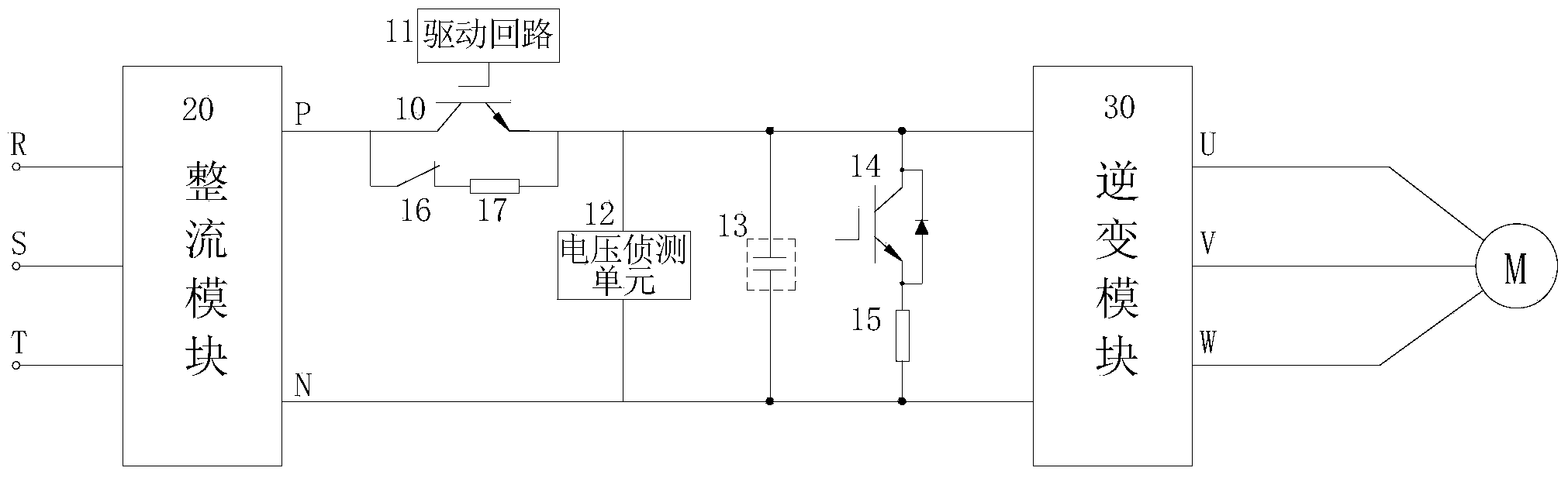

[0039] This example utilizes the elevator load controller provided by this program to form a new type of elevator inverter, in which the electronic switch that can be turned off uses IGBT, the detection of the electronic switch that can be turned off uses voltage detection, and the charging circuit uses soft contact devices and soft-start resistors.

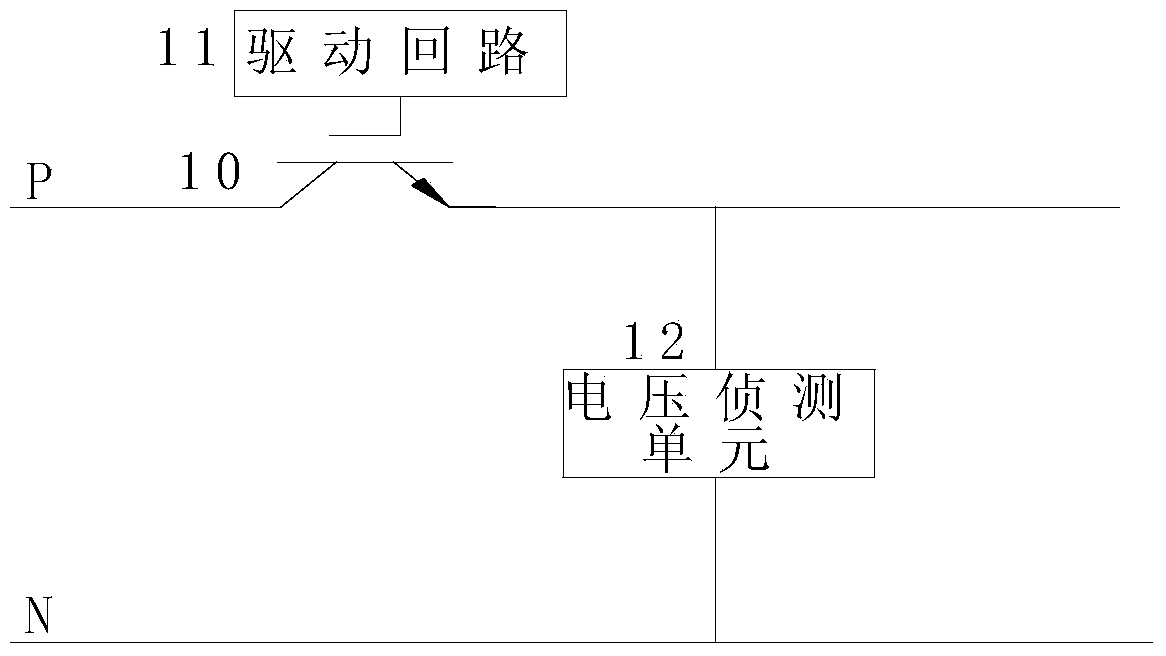

[0040] see image 3 , which shows the system architecture diagram of this example. As can be seen from the figure, the entire application system includes a drive circuit 11, an IGBT 10, a voltage detection unit 12, a smoothing capacitor 13, a pick-up crystal 14, a pick-up resistor 15, a soft-start contactor 16, a soft-start charging resistor 17, a rectifier module 20, inverter module 30 .

[0041] Among them, the P terminal of the three-phase AC power supply rectified by the rectifier module is connected to the upper end of the IGBT 10, and the two ends of the IGBT 10 are connected in parallel with the soft-start charging resis...

example 2

[0049] This example utilizes the elevator load controller provided by this solution to form another new type of inverter for elevators. The electronic switch that can be turned off uses IGBT, the detection of the electronic switch that can be turned off uses current detection, and the charging circuit can be used directly. This is achieved by turning off the duty cycle of the electronic switch conduction.

[0050] see Figure 4 , which shows the system architecture diagram of this example. As can be seen from the figure, the entire application system includes a drive circuit 11, an IGBT 10, a voltage detection unit 12a, a current detection unit 12b, a smoothing capacitor 13, a pick-up crystal 14, a pick-up resistor 15, an inductor 18, a freewheeling diode 19, a rectifier Module 20, inverter module 30.

[0051] Wherein, the P terminal of the three-phase AC power rectified by the rectifier module 20 is connected to the upper terminal of the IGBT 10, the lower terminal of the I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com