Longquan celadon iron glaze and method for manufacturing celadon iron glaze product by using same

A technology of celadon and iron glaze, which is applied in the field of ceramic technology, can solve problems such as reaching 93°C, achieve thick and full taste, reduce high blood pressure, and prevent high blood pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in combination with specific embodiments. It should be noted that each raw material in the glaze formulation involved in the present invention is produced in Longquan City, Zhejiang Province, and its names and components are clear to those skilled in the relevant fields.

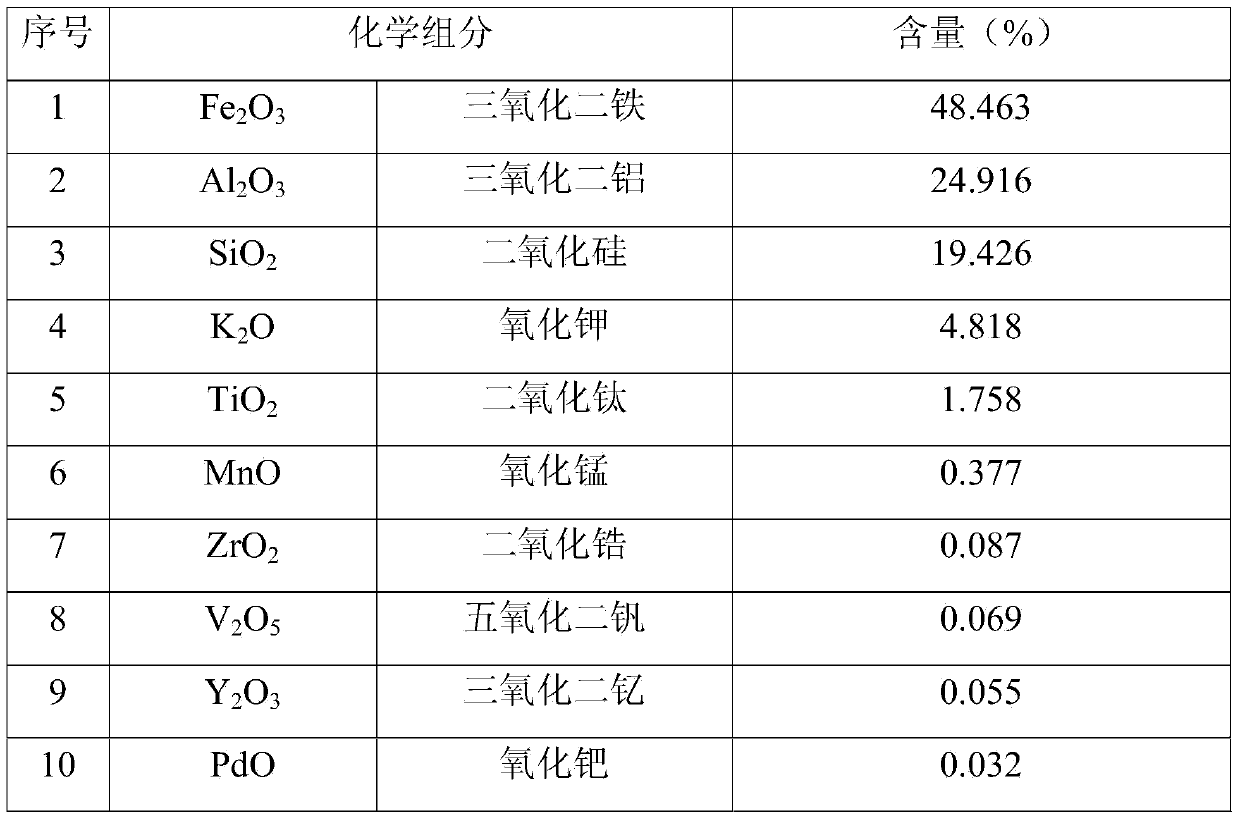

[0026] The Longquan celadon iron glaze of the present invention comprises the following glaze ingredients in weight percent: 35-45% of Baoxi glaze soil, 6-9% of limestone, 6-9% of quartz, 18-20% of big kiln purple gold soil, iron ore 23-25%, Badu fluorspar 1.2-2%.

[0027] The present invention uses above-mentioned Longquan celadon iron glaze to make the method for celadon iron glaze product, comprises the following steps:

[0028] (1) Glaze preparation: choose the glaze batching weight percentage to form: Baoxi glazed soil 41%, limestone 7%, quartz 8%, Dayao purple gold soil 18.6%, iron ore 24%, Badu fluorspar 1.4%.

[0029] The above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com