Arc sealing device for pipeline or drill pipe hole forming under pressure and using method

A sealing device and arc-shaped technology, used in drill pipe, drill pipe, casing and other directions, can solve the problems of short life, hidden danger, liquid leakage, etc., and achieve long extrusion resistance, good sealing performance and unique structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

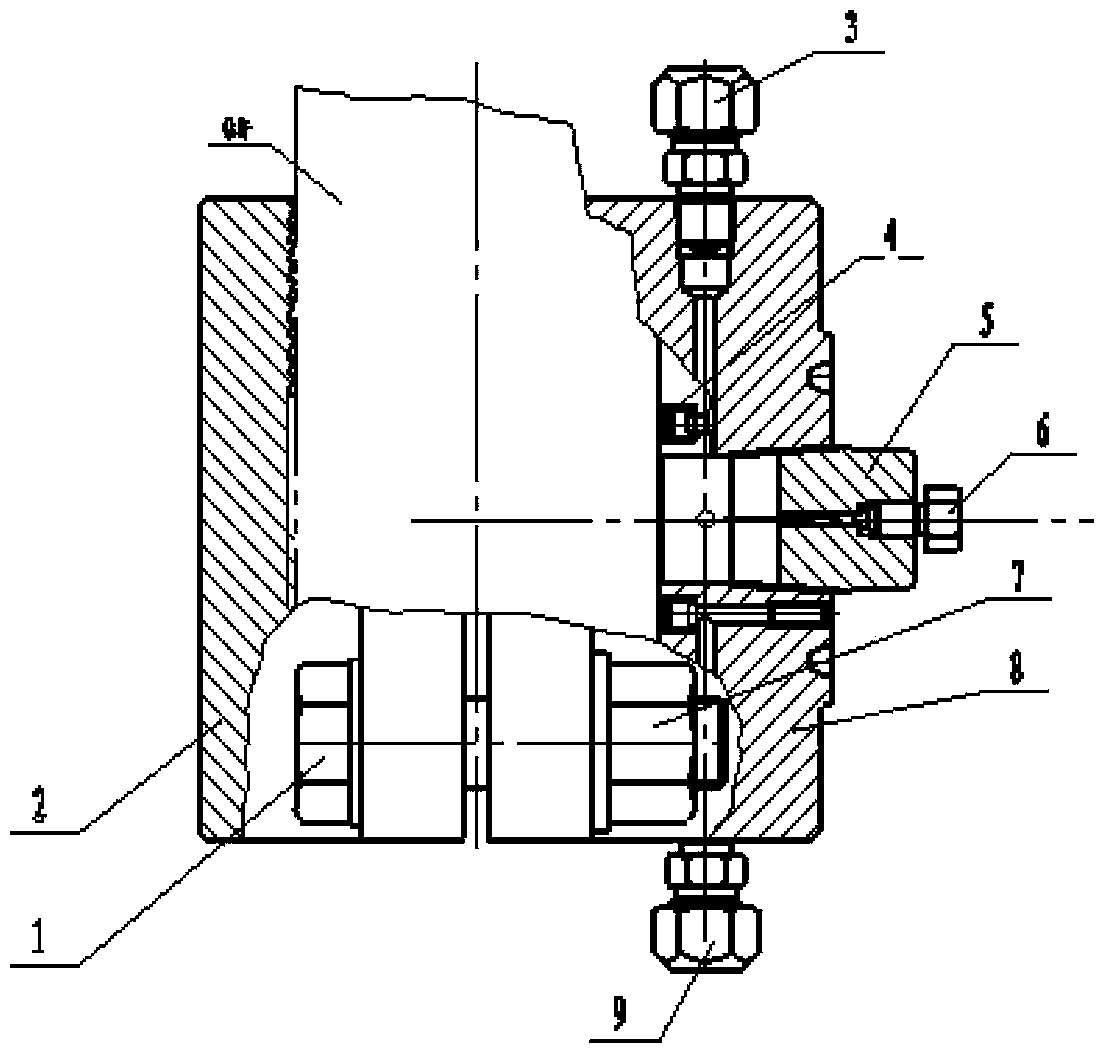

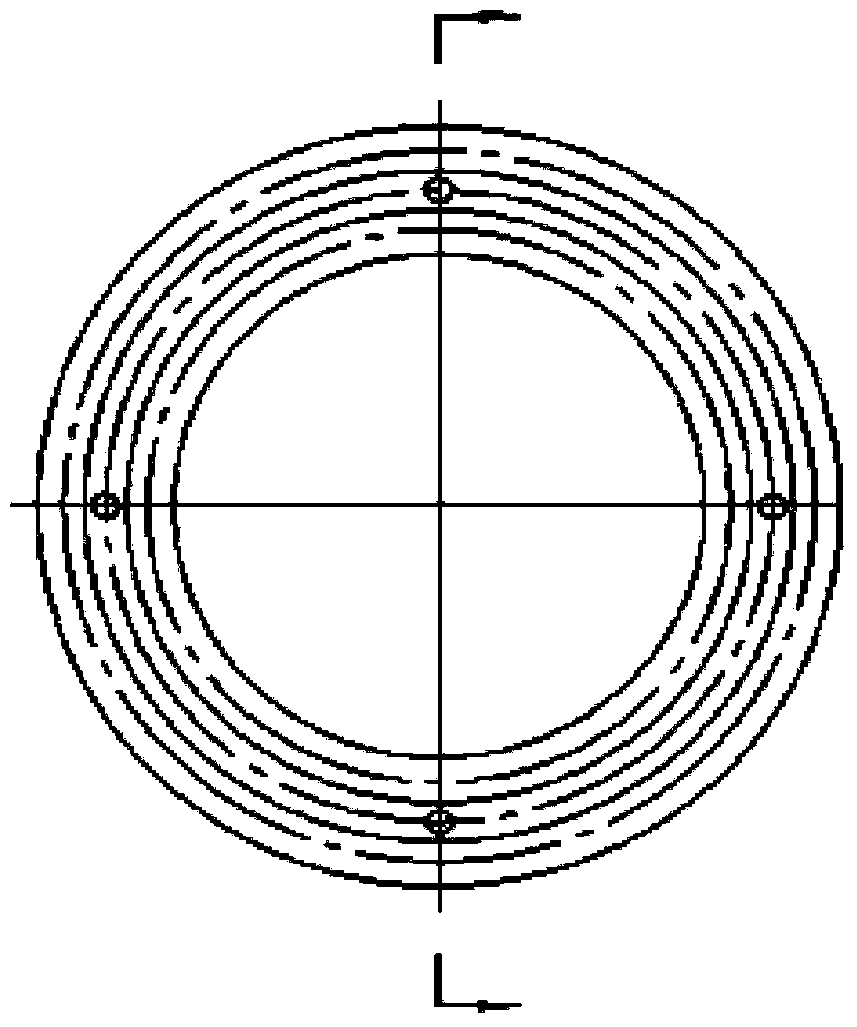

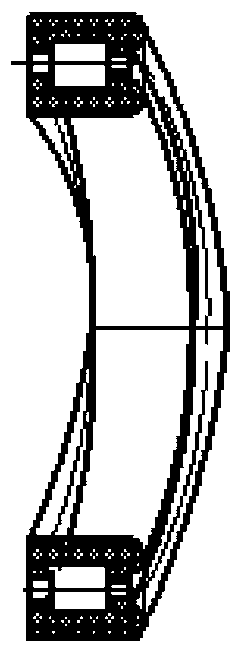

[0027] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 as shown,

[0028] When the grease injection pressure of the manual pressure test pump reaches 120Mpa, the sealing device can seal liquid up to 70Mpa.

[0029] Such as figure 1 As shown, the arc sealing test device and test method for the pressurized pipeline or drill pipe opening related to the present invention include two hoops on the drill pipe—an anti-slip hoop and a sealing hoop, both hoops are There is an arc groove, and there is an arc sealing ring installed in the arc groove of the sealing hoop. figure 2 with image 3 In the arc seal groove shown, the arc seal ring is installed in the seal groove, and the drill pipe is hugged by fasteners such as hexagonal bolts and nuts, and tooth-shaped teeth are set in the arc groove of the anti-skid hoop; The sealing hoop is provided with a drilling channel communicating with the arc groove, and the right end of the drilling channel is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com