Antifreeze and defrost type solar plate collector

A solar panel and collector technology, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., can solve the problem of decreased use efficiency, increased energy consumption, and freezing of solar panel collectors. and other problems, to achieve the effect of improving defrosting efficiency and good anti-freezing and heat preservation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below picture and The specific embodiment will further describe the present invention.

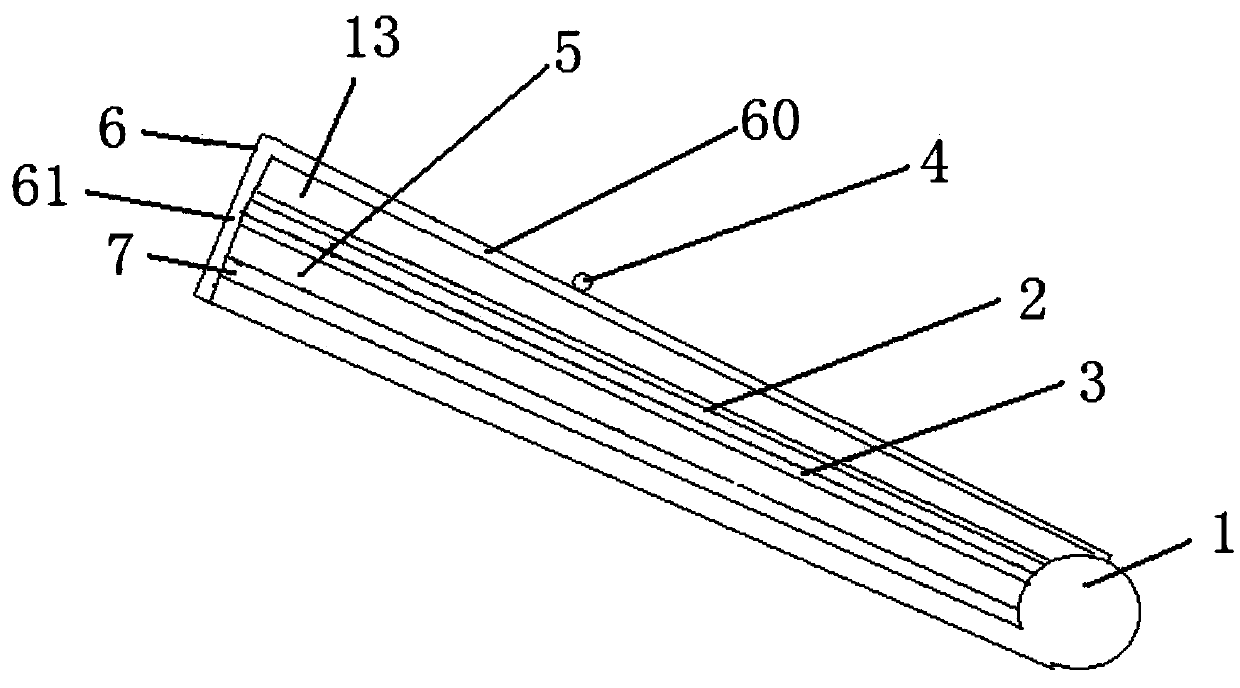

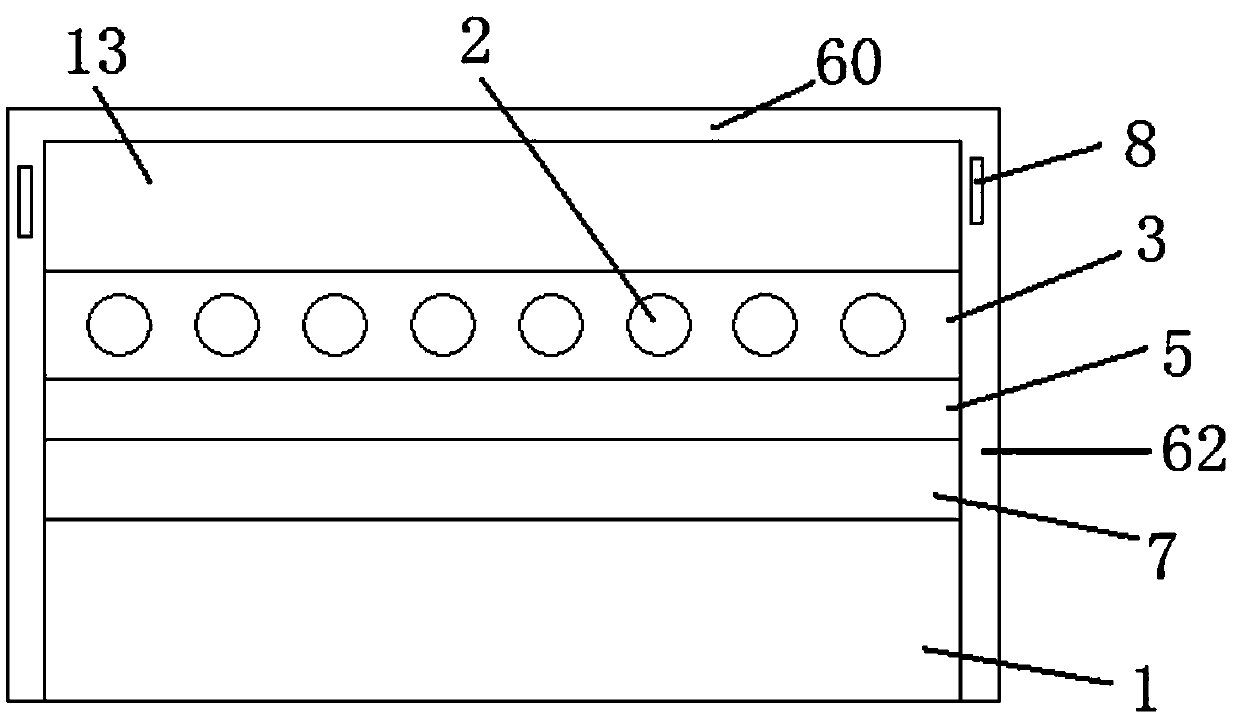

[0024] Figure 1, figure 2 , image 3 In the described embodiment, the antifreeze and defrost type solar flat panel heat collector, the solar flat panel heat collector is connected to a heat pump, includes a base plate 1, a heat collection plate 3, a refrigerant pipe 2, an outer frame 6 and a single-chip microcomputer, and the heat collection plate 3 is installed on the On the bottom plate 1, the refrigerant pipe 2 is installed inside the heat collecting plate 3, the refrigerant pipe 2 and the heat collecting plate 3 are integrally formed, the outer side of the refrigerant pipe 2 is attached with an electric heating cable, and the outer frame 6 covers the heat collecting plate 3 and the bottom plate 1, a cavity 13 is formed between the outer frame 6 and the heating plate 3, and the side of the outer frame 6 and placed at the position of the cavity 13 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com