Heat preservation anti-freezing structure and method for acid and alkali equipment in power plant

An acid-base and equipment technology, which is applied in the field of heat preservation and antifreeze structure of acid-base equipment in power plants, can solve the problems of easy corrosion, pulverization, heat preservation and corrosion of the outer shield, and easy water seepage of the outer shield, so as to improve the heat preservation and antifreeze Effect, good waterproof effect, beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

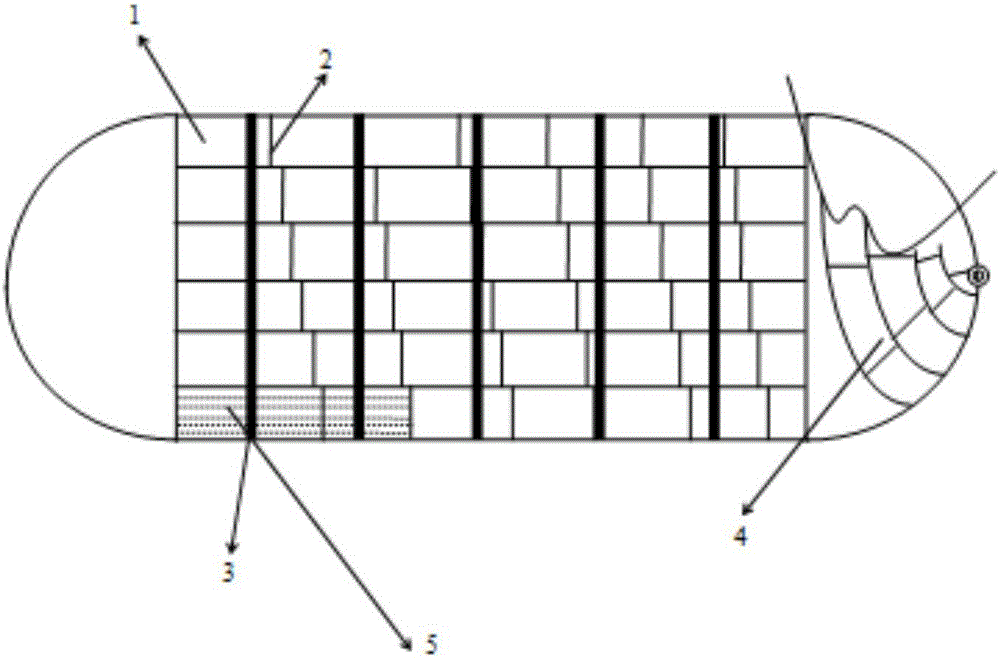

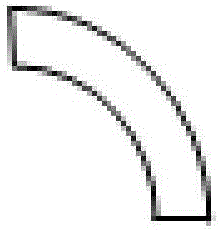

[0034] Such as figure 1 As shown, the heat preservation and antifreeze structure of the acid-base equipment in the power plant includes the first heat-insulation board for covering the ring-direction cylinder of the acid-base equipment and the second heat-insulation board for covering the ends of the acid-base equipment, the first heat-preservation board, the second The two insulation boards can be spliced or overlapped, and the shape after splicing and lapping is the same or similar to that of the acid-base equipment. The adjacent first insulation board and the second insulation board are sealed with sealant or insulation glue. A thermal insulation board includes a plurality of spliced or lapped first thermal insulation blocks, that is, a cylinder thermal insulation block 1, and a second thermal insulation board includes a plurality of spliced or lapped second thermal insulation blocks, that is, a head thermal insulation block 4, and the adjacent first The insulation bl...

Embodiment 2

[0044] Firstly, the length of the acid-base equipment cylinder is measured on site, and the measured length is divided into two parts.

[0045] First, measure the length of the barrel. The measurement starting point is from the weld seam of the straight pipe section at the end of the equipment to the weld seam between the other end of the equipment and the head.

[0046] Second, measure the bending diameter of the head. Measured from the center of the head. Record the data after measurement. According to the measured data and combined with the size of the equipment installation drawing, the first insulation block and the second insulation block of polyurethane material are manufactured. The size of each first insulation block is about 1000mm×600mm×δmm, and the thickness δ is produced according to the requirements of the drawing.

[0047] The method of heat preservation and antifreeze for acid and alkali equipment in power plants, the specific steps are as follows:

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com