Gas microflow detection device based on flow sensing mechanism of poison hairs of scorpions

A flow sensing and detection device technology, which is applied to measurement devices, fluid velocity measurement, volume/mass flow generated by electromagnetic effects, etc., can solve the problems of high price, high power consumption, and low mechanical detection accuracy, and achieves a simple process. , high sensitivity, good economy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

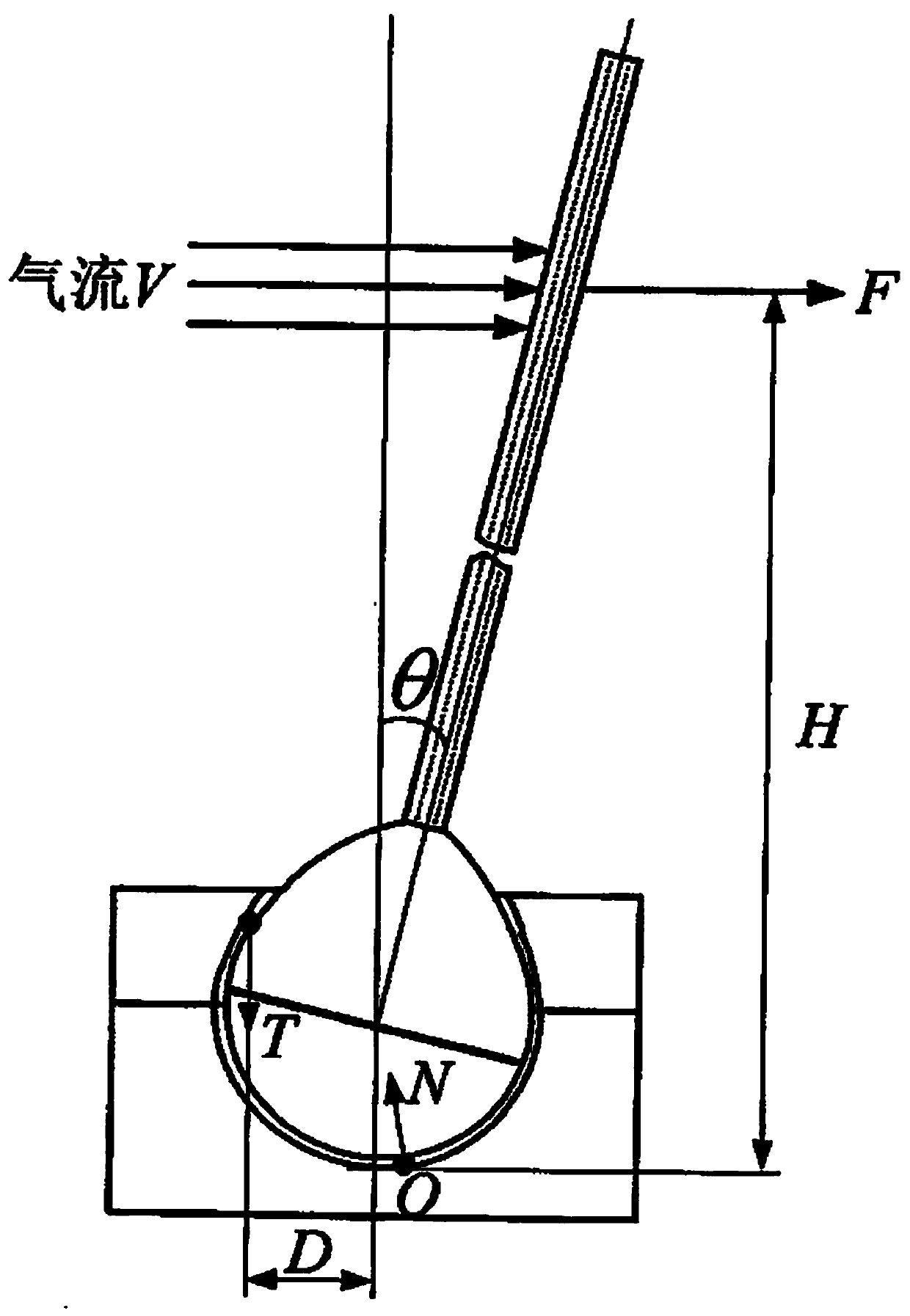

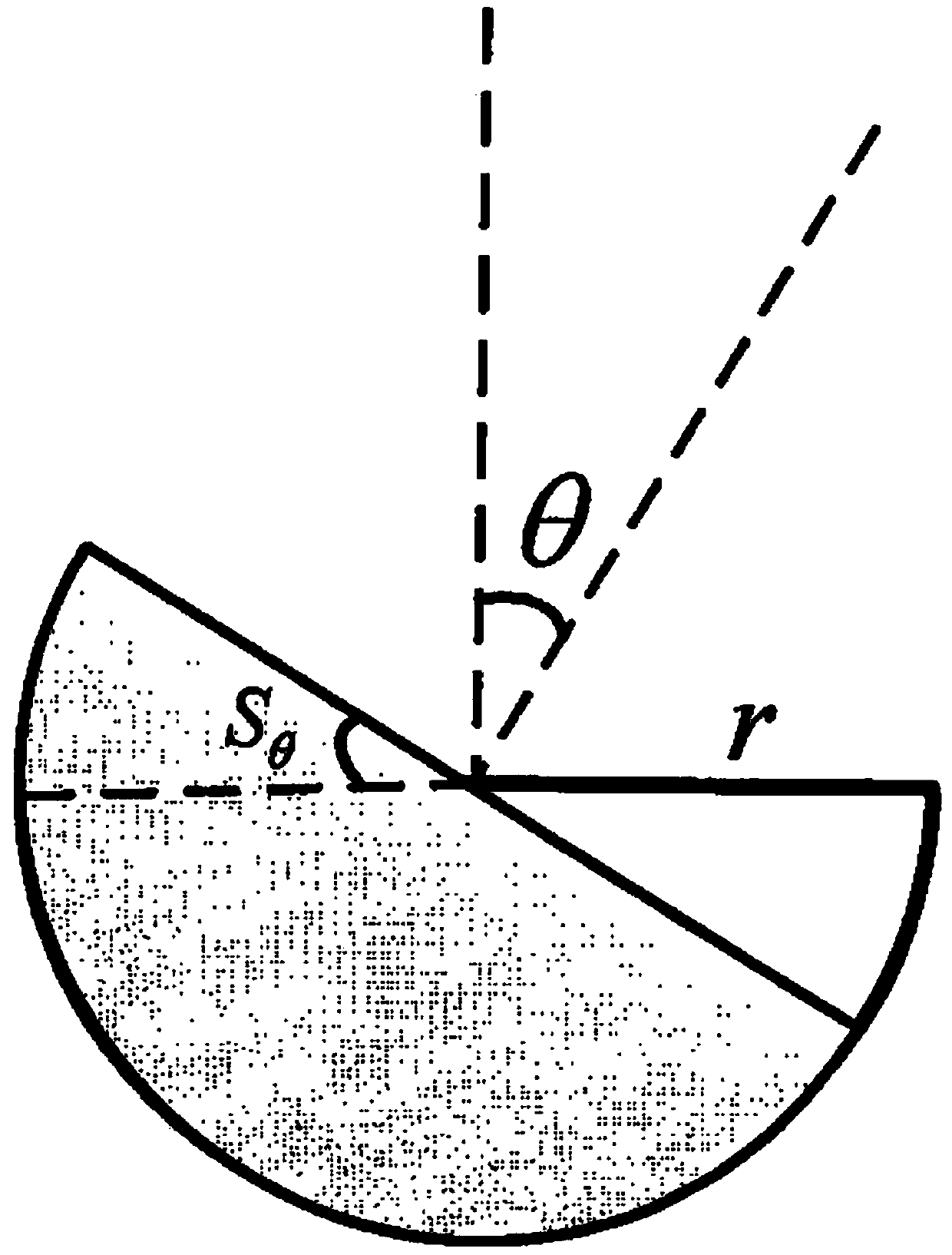

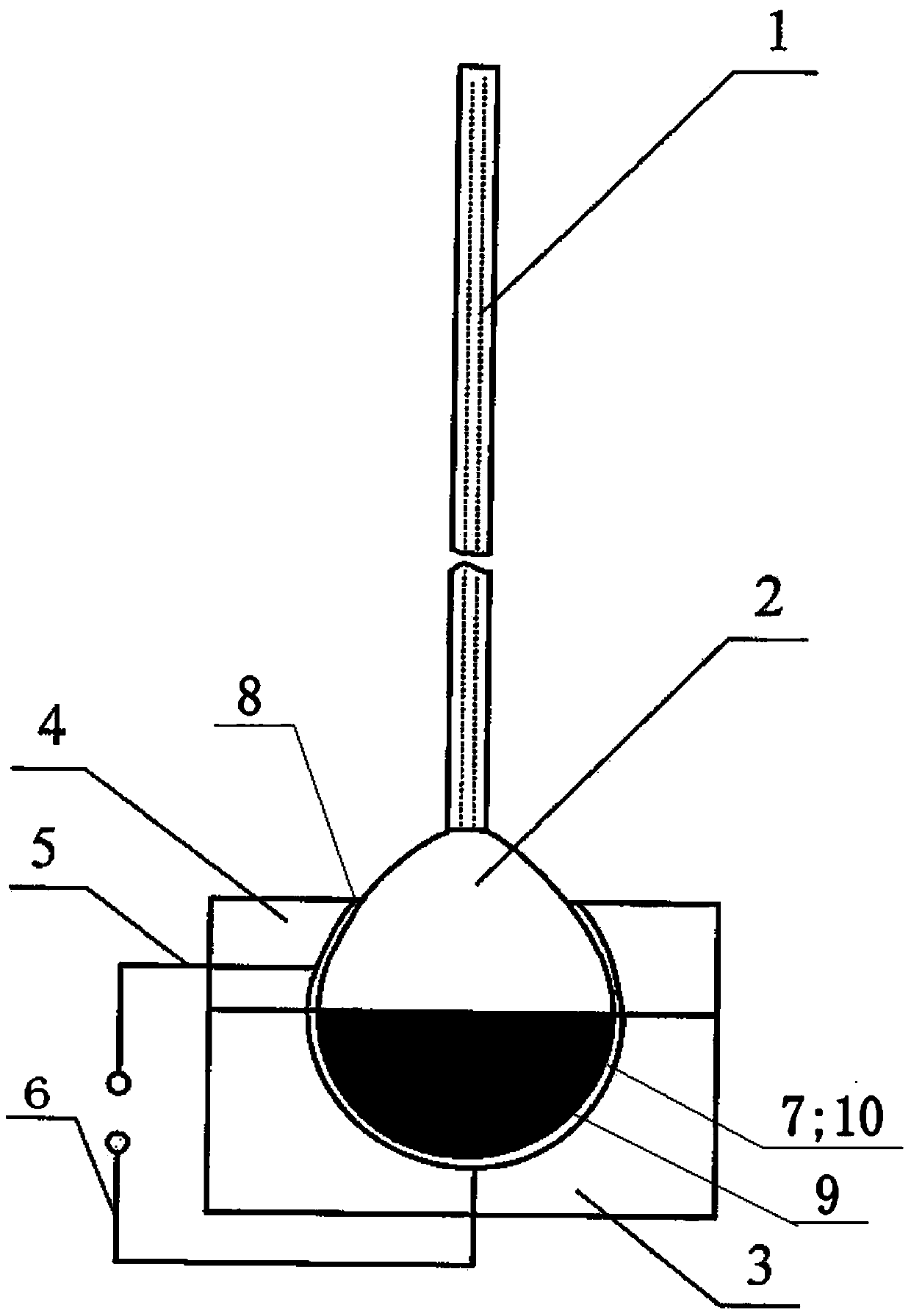

[0021] see figure 1 Shown, the present embodiment is made up of class Gu hair rod 1, class Gu hair base 2, class Gu hair seat 3, elastic connecting film 4, first electrode lead 5 and second electrode lead 6, class Gu hair rod 1 and The fur-like base 2 is assembled into one body to form a hair-like structure; the lower half of the hair-like base 2 has a conductive coating 9, and the hair-like base 2 is installed on the hair-like body after the hair-like base 3 and the elastic connecting film 4 are assembled. In the spherical cavity 7; the upper part of the elastic connecting film 4 has an opening 8, and the size of the opening 8 of the elastic connecting film 4 limits the swing angle of the vellus-like hair rod 1; When swinging, it is connected with the conductive coating 9 of the vellus-like base 2; the vellus-like seat 3 is a cylindrical insulator, and the hemispherical groove 10 of the 3-like vellus seat 3 can just support the free swing of the vellus-like base 2 , the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com