Coupling simulation system and method used for vibrating and loading bogie assembly with multi-degree of freedom

A technology for simulating systems and degrees of freedom, applied in vibration testing, measuring devices, railway vehicle testing, etc., can solve problems such as the inability to simulate the overall performance of bogies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

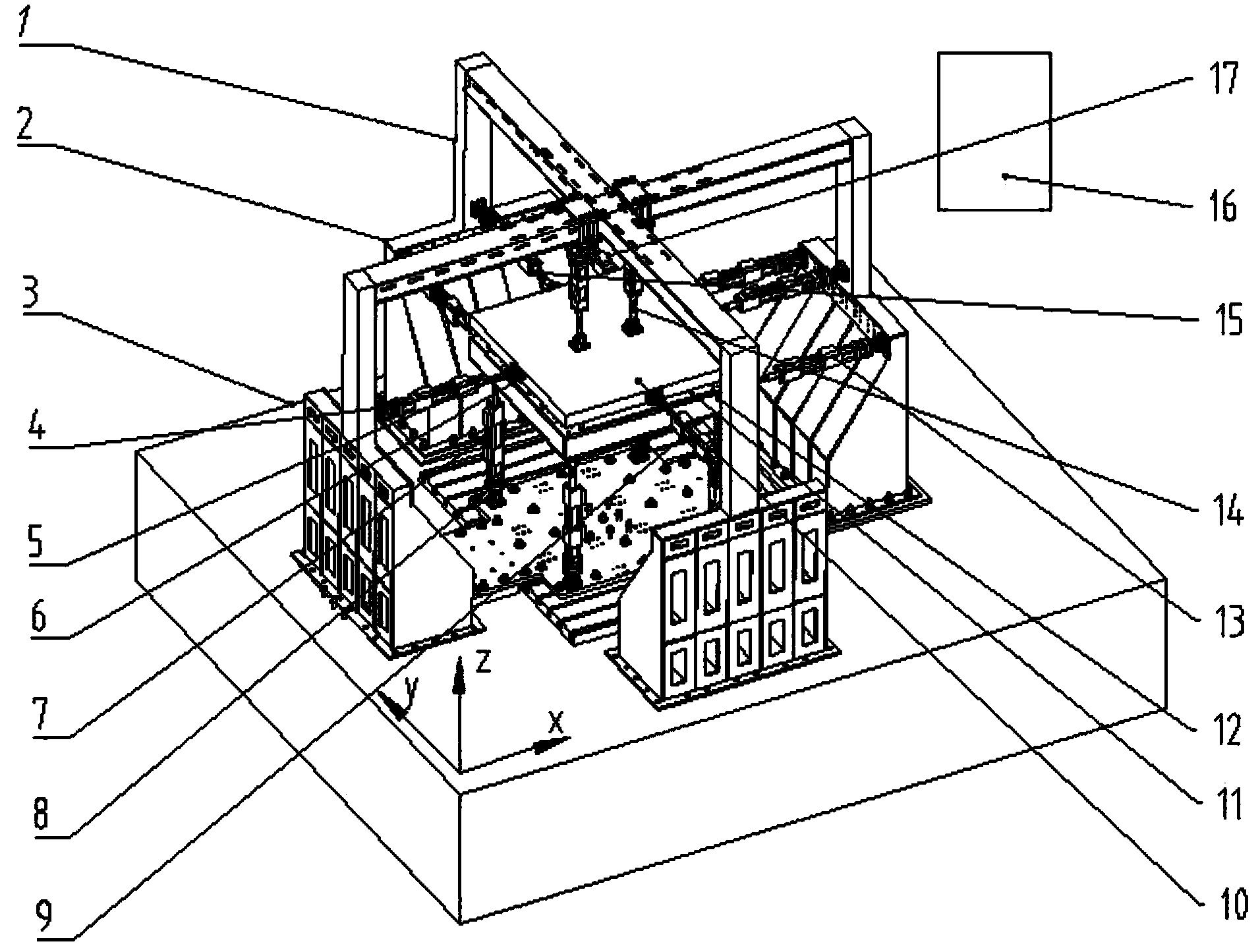

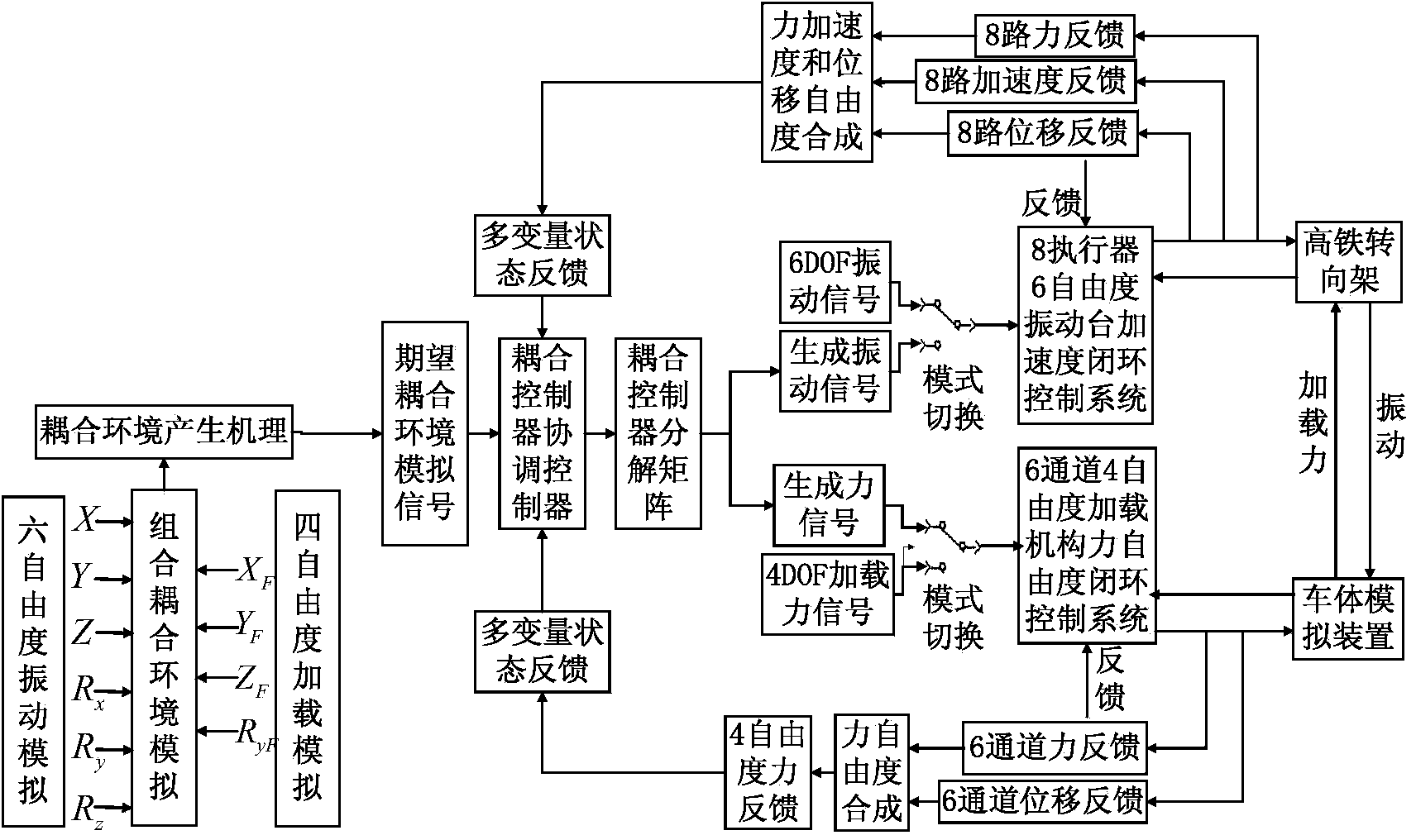

[0021] Embodiment 1: The high-speed train bogie integrated coupling simulation system includes a control system and a control method;

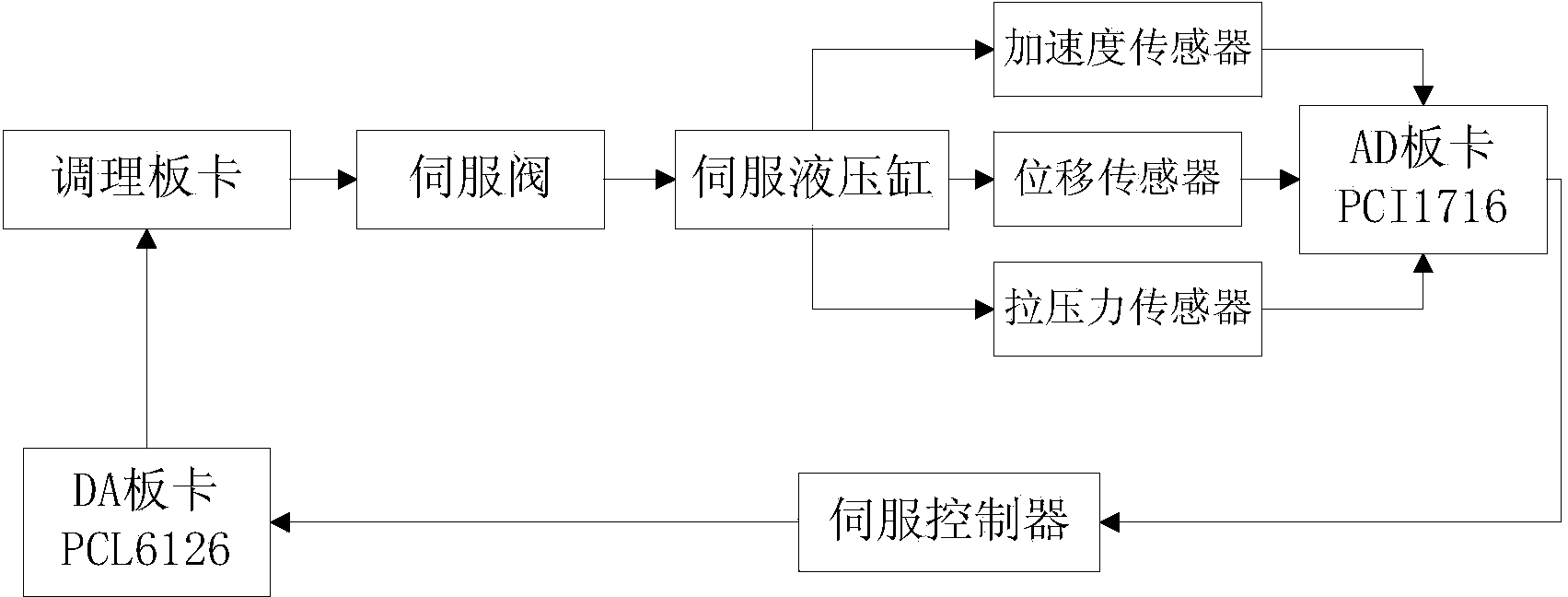

[0022] The control system includes a six-degree-of-freedom vibration test bench, an AD board PCI1716, a DA board PCL6126, and multiple sets of servo hydraulic cylinder control systems, and each set of servo hydraulic cylinder control systems includes a vibration exciter control system and a force loading control system. system;

[0023] The vibration exciter control system includes an excitation servo hydraulic cylinder, an excitation electro-hydraulic servo valve, an excitation tension pressure sensor, an excitation displacement sensor, an excitation acceleration sensor and an excitation servo controller; The excitation electro-hydraulic servo valve is installed on the excitation servo hydraulic cylinder, one end of the excitation pull pressure sensor is connected to the cylinder rod of the hydraulic cylinder, and the other end is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com