Temperature field simulation design method for low-voltage distribution cabinet

A simulation design, power distribution cabinet technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems affecting the research and development speed of low-voltage power distribution cabinets, heating of low-voltage power distribution cabinets, and high research and development costs. The effect of de-experimenting process, improving efficiency and improving success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0057] A temperature field simulation design method for a low-voltage power distribution cabinet, comprising the following steps:

[0058] Step 1. Use 3D software to establish an equivalent model, import the model file (.x_t) into ICEM-CFD software, establish an air field around the low-voltage power distribution cabinet, form a fluid-solid coupling heat dissipation model, and use ICEM-CFD to conduct Mesh division.

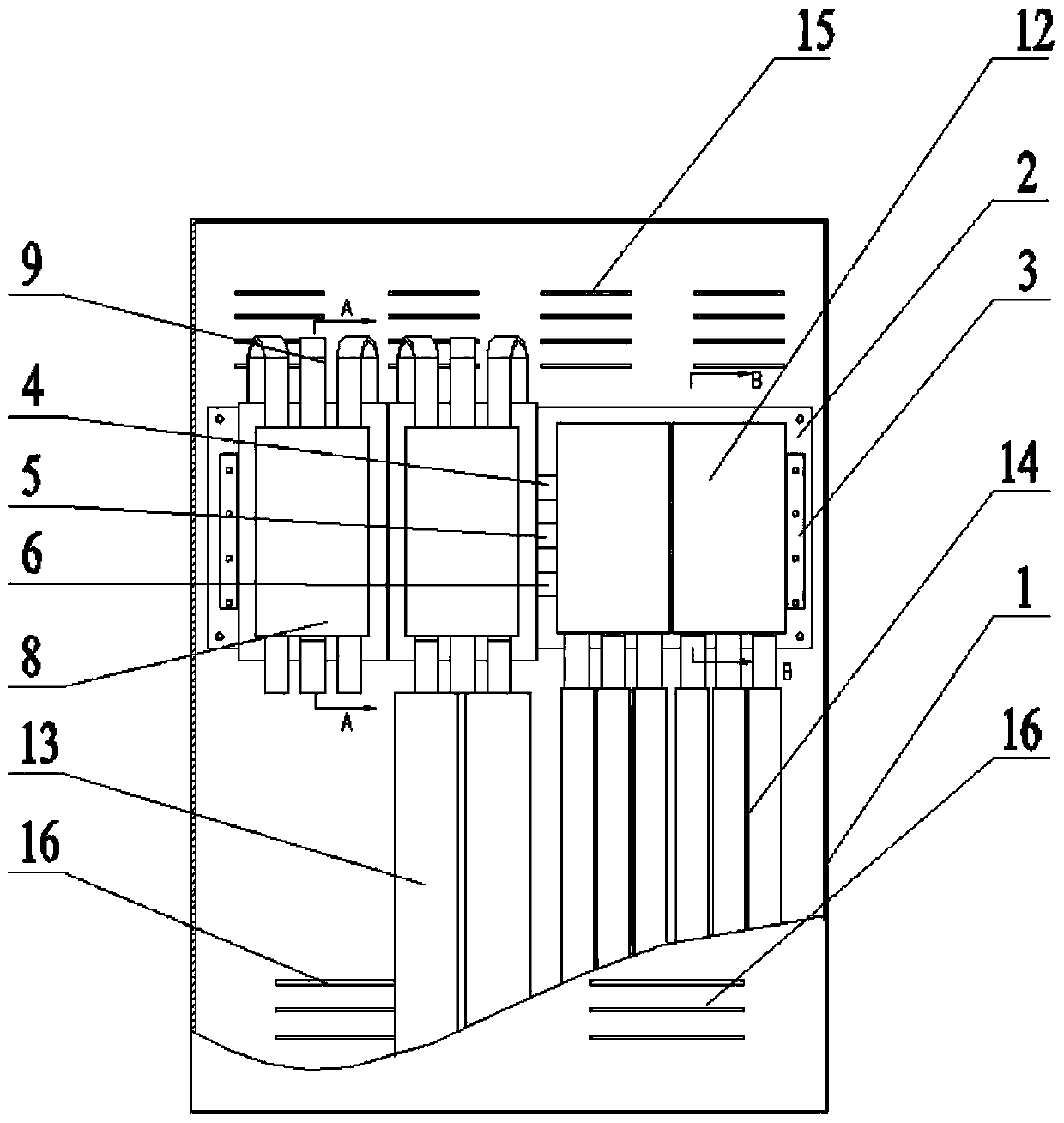

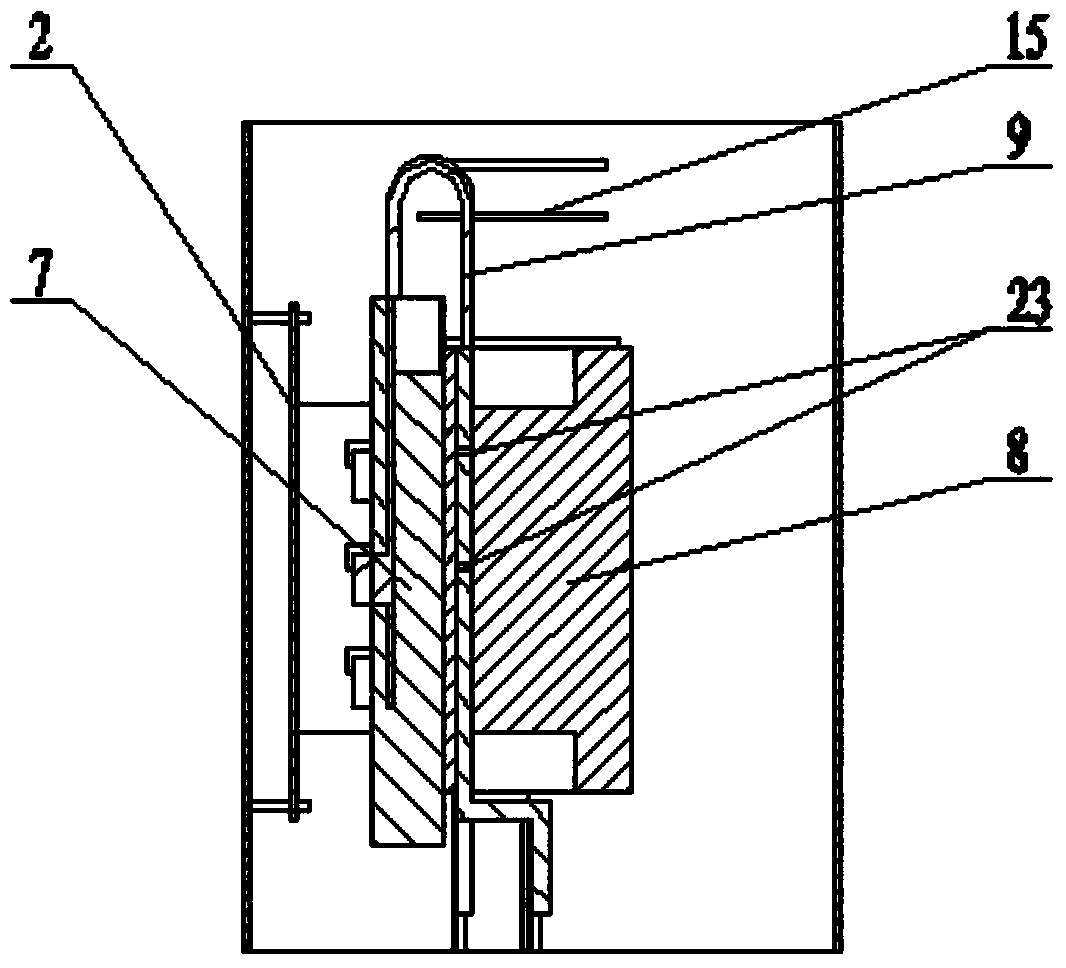

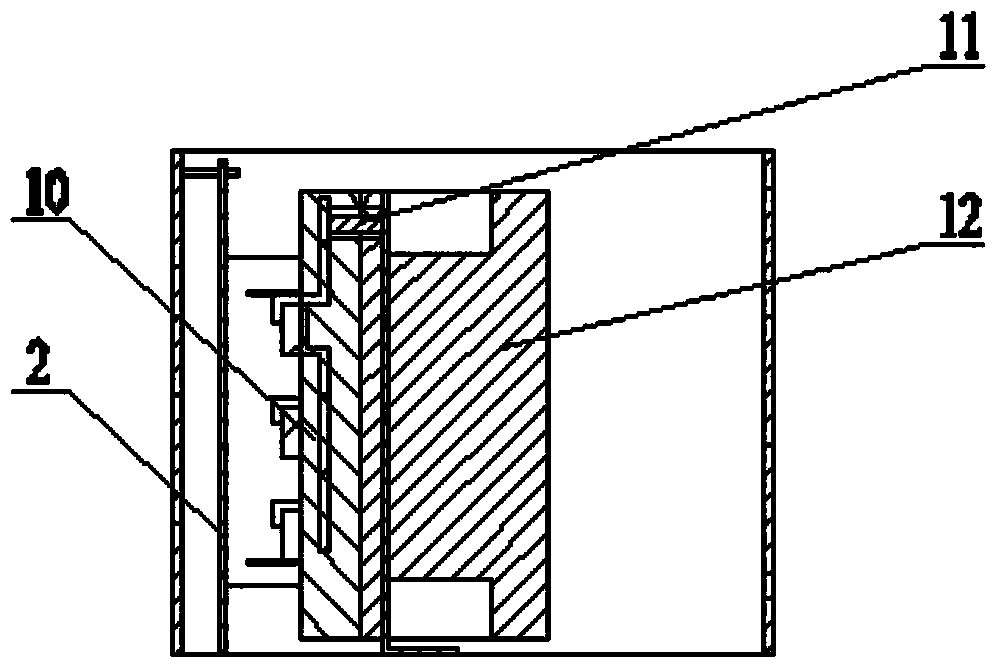

[0059] The 3D equivalent model used in this step, such as Figure 1 to Figure 3 As shown, in this model, the support plate 2 is connected with the studs reserved for the shell 1 of the low-voltage cabinet through nuts; C is fixed to bus 6; In=630A adapter 7 is connected to bus ABC, In=630A circuit breaker 8 is connected to In=630A adapter 7 via soft bus 9; In=400A adapter 10 is connected On the busbar ABC, it is connected with an In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com