Three-phase magnetic cores for magnetic induction devices and methods for manufacturing them

A magnetic induction device and magnetic core technology, which is applied in the fields of magnetic core manufacturing, transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, etc., can solve complex production technology problems, reduce electrical loss, simplify assembly and disassembly, Effect of reduced diameter and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

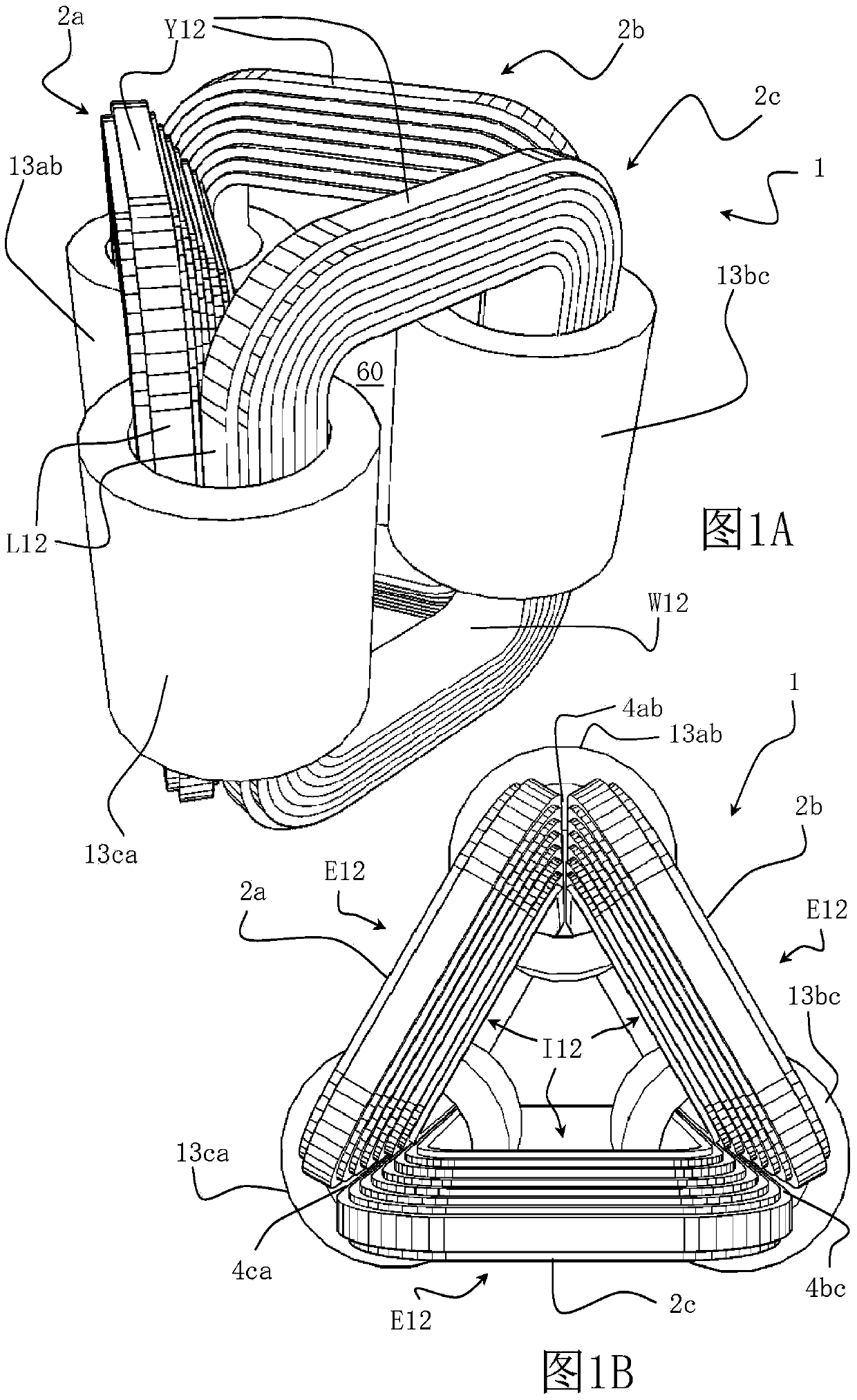

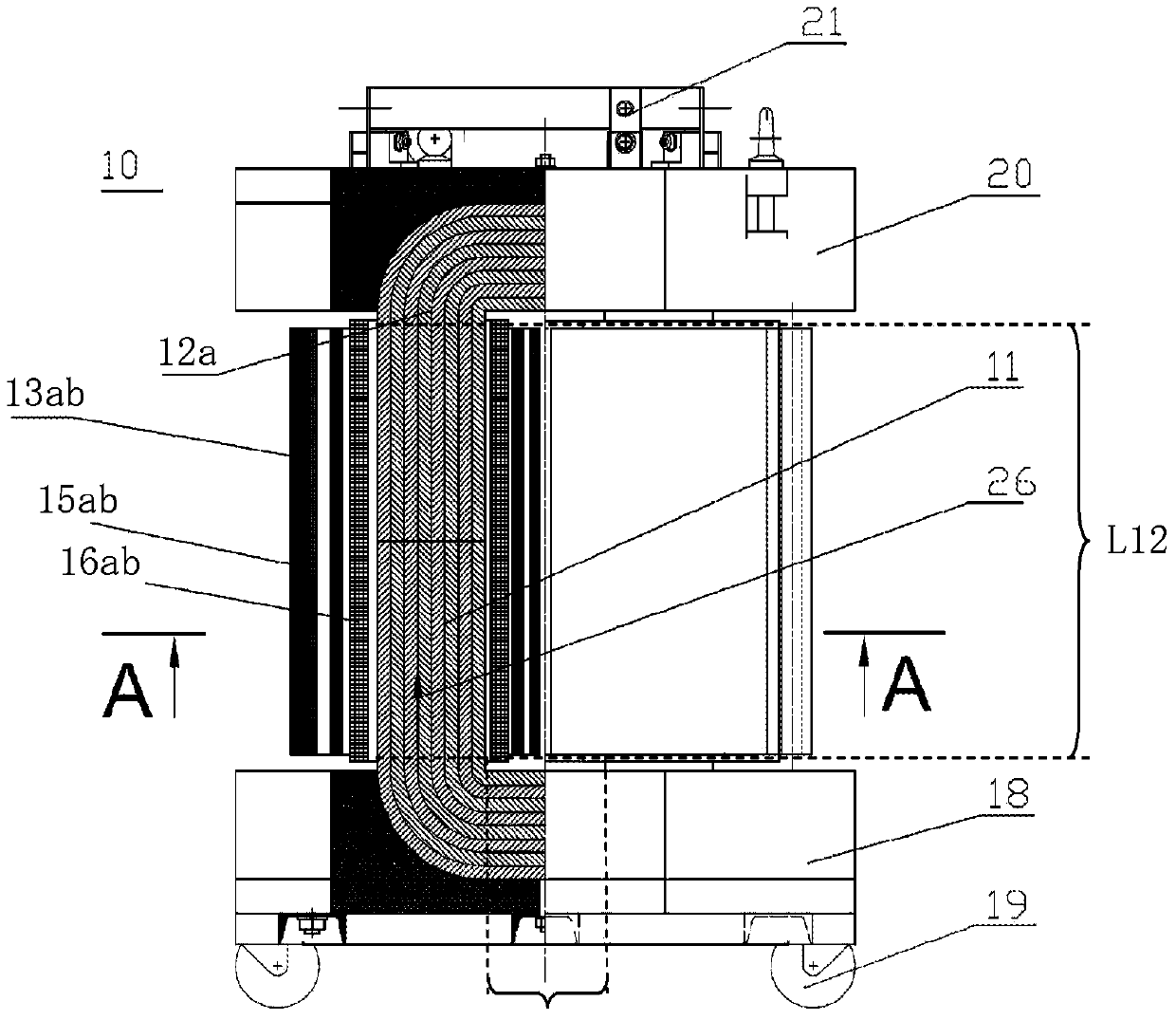

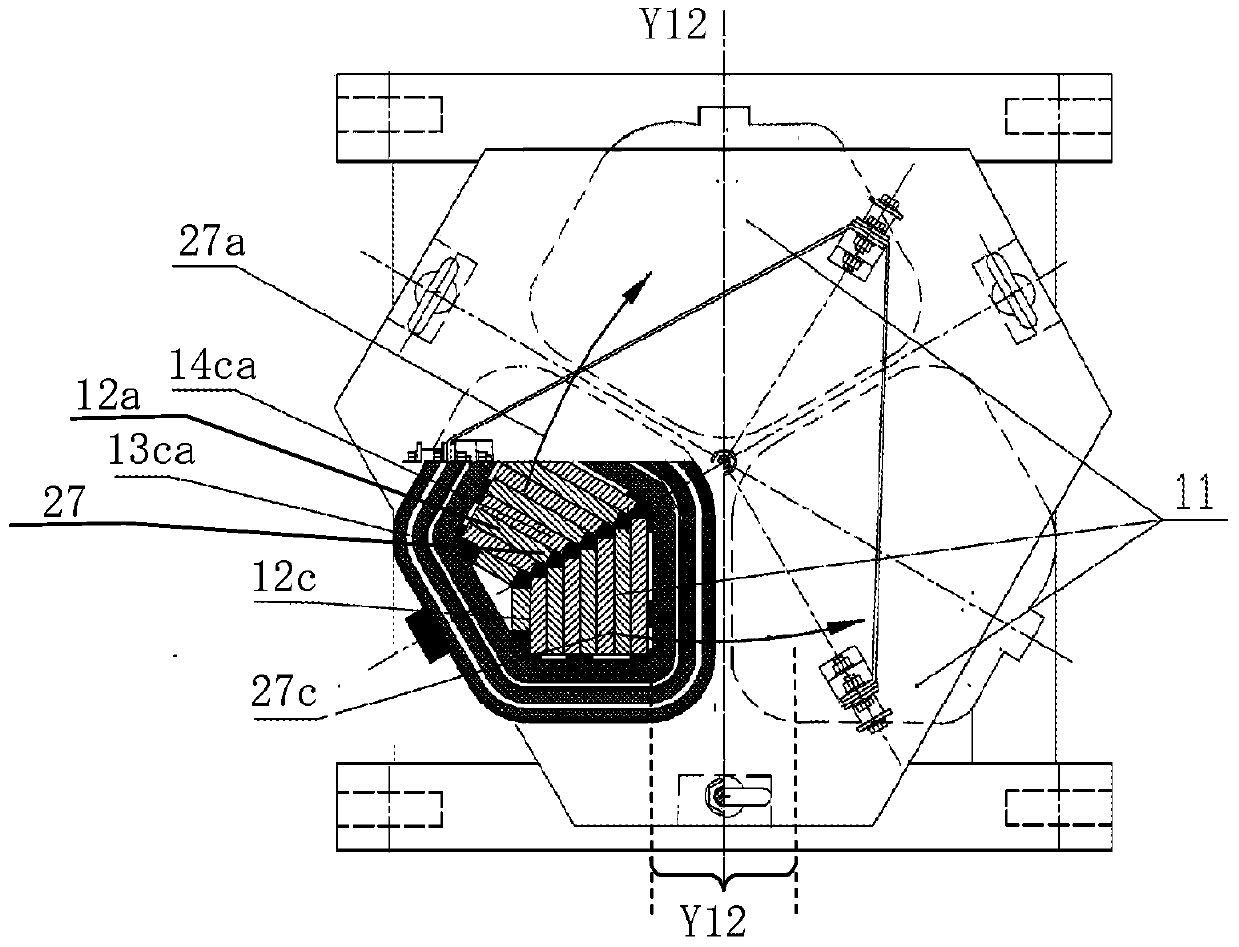

[0062] This application is generally directed to magnetic core circuits for three-phase magnetic induction devices, such as, but not limited to, three-phase choke coils and three-phase transformers. The three-phase magnetic core circuit of the present invention is constructed of a magnetic core frame having a stepped configuration formed on at least one face of the frame and extending along their sides. The core loop is constructed by placing frames locally adjacent one another to form a triangular (triangular prism) structure, wherein the stepped sides of each frame evenly engage the adjacent positioned frames. Stepped sides. The evenly joined sides of these frames form the magnetic core legs on which the coil modules of the magnetic induction device are to be placed.

[0063] As should be apparent from the following disclosure, this core design improves the distribution of magnetic flux in the core circuit and reduces electromagnetic losses that typically occur in the core....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com