An online cleaning device and method for a trough-type liquid distributor

A liquid distributor and cleaning device technology, applied in the direction of fractionation, etc., can solve the problems of increased difficulty in shutdown and maintenance, affecting the normal production of the device, etc., to achieve the effect of prolonging the production operation cycle, good application prospects, and improving the effect of liquid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

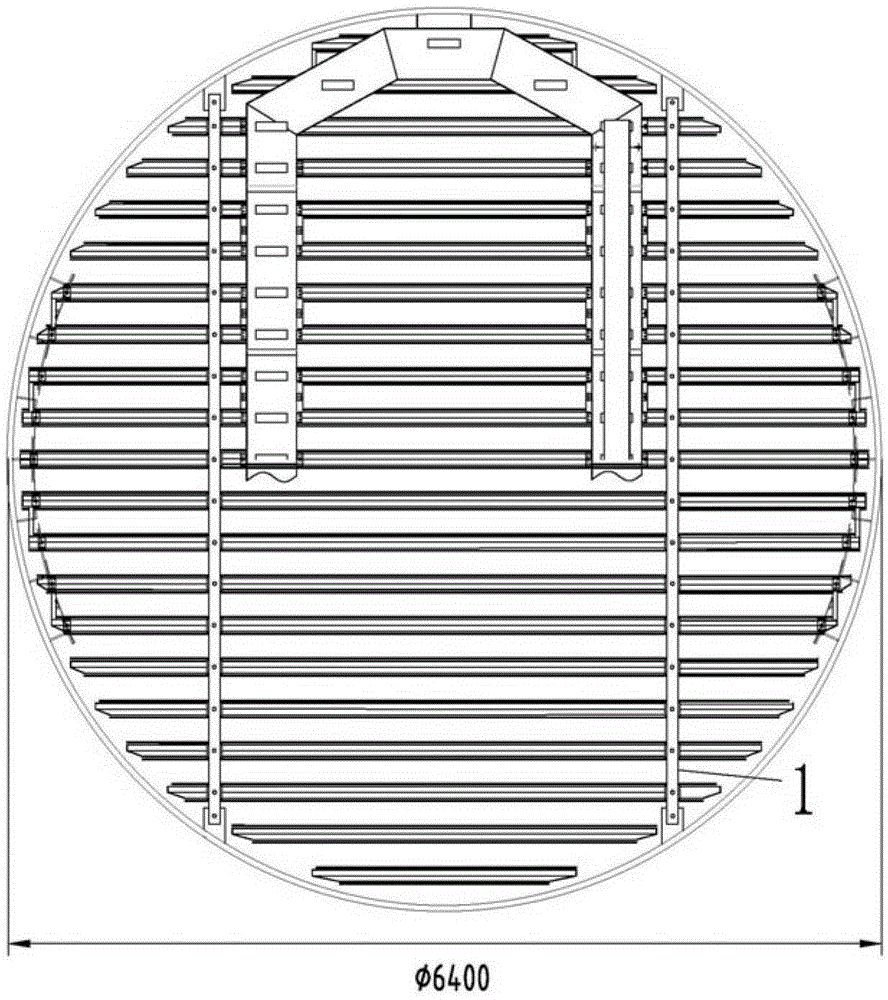

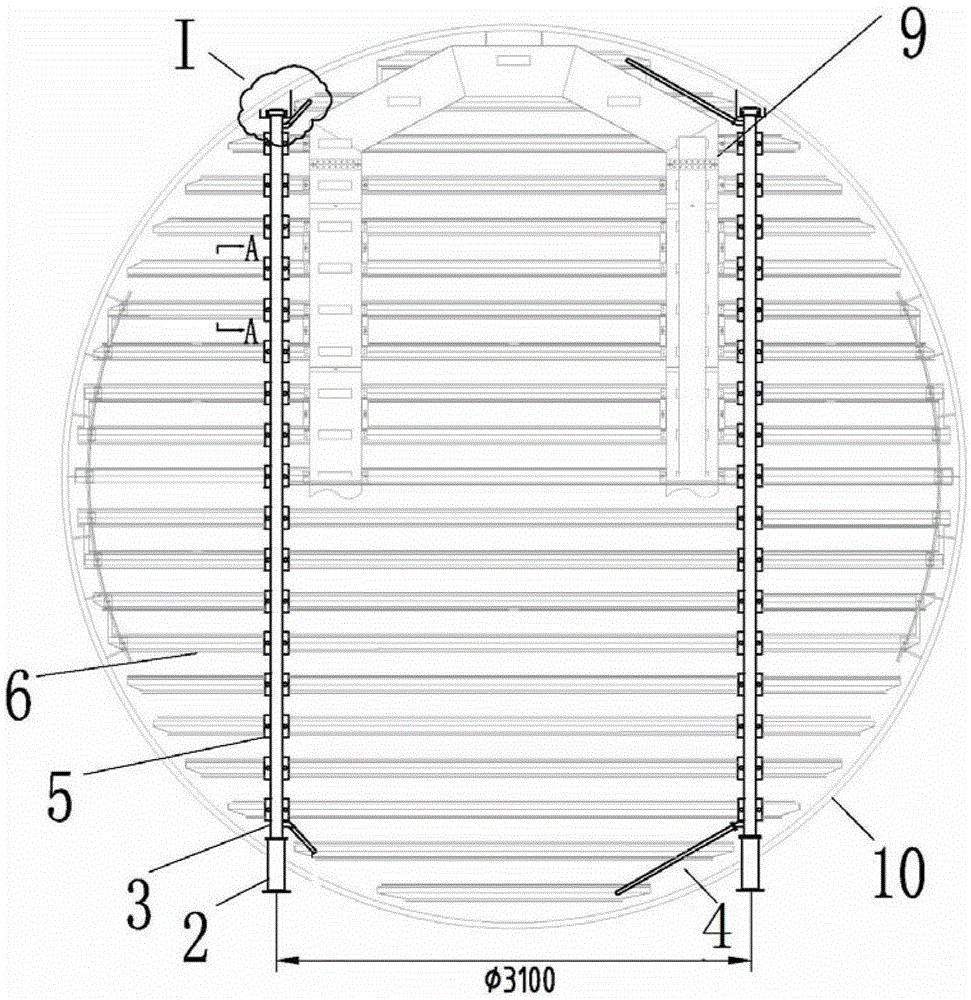

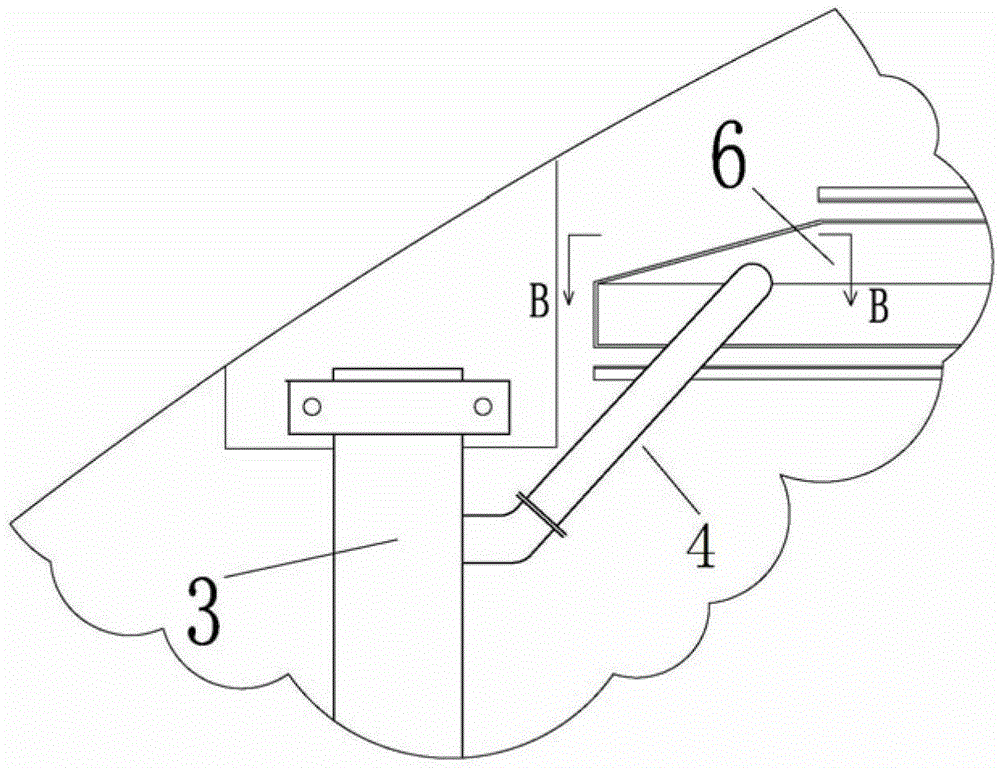

[0036] like figure 2 As shown, an online cleaning device for a trough-type liquid distributor is arranged above the trough-type liquid distributor on the packed bed at the top of the vacuum tower. The trough-type liquid distributor is provided with 21 secondary distribution tank 6. The online cleaning device includes: two flushing main pipes 3 and flushing branch pipes 4; the cleaning main pipe 3 is placed at the hanging beam position of the secondary distribution tank 6, which also serves as a support function, and the hanging beam is no longer installed separately to save investment. One end of the flushing main pipe 3 is connected to the nozzle 2 arranged on the tower wall, and the other end is welded to a support fixed on the inner side of the tower wall; lifting lugs 5 are welded on both sides of the flushing main pipe 3 for hoisting the secondary distribution tank.

[0037] One end of the flushing branch pipe 4 communicates with the flushing main pipe 3 , and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com