Preparation and modification methods of metal-organic frame material Bi-BTC for adsorbing CO2

An organic framework and metal technology, applied in the field of preparation of metal-organic framework material Bi-BTC and its modified products, can solve the problems of liquid ammonia on equipment corrosion, waste of resources, large water vapor consumption, etc., and achieve good industrial application Foreground, solve the effect of low pressure adsorption is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

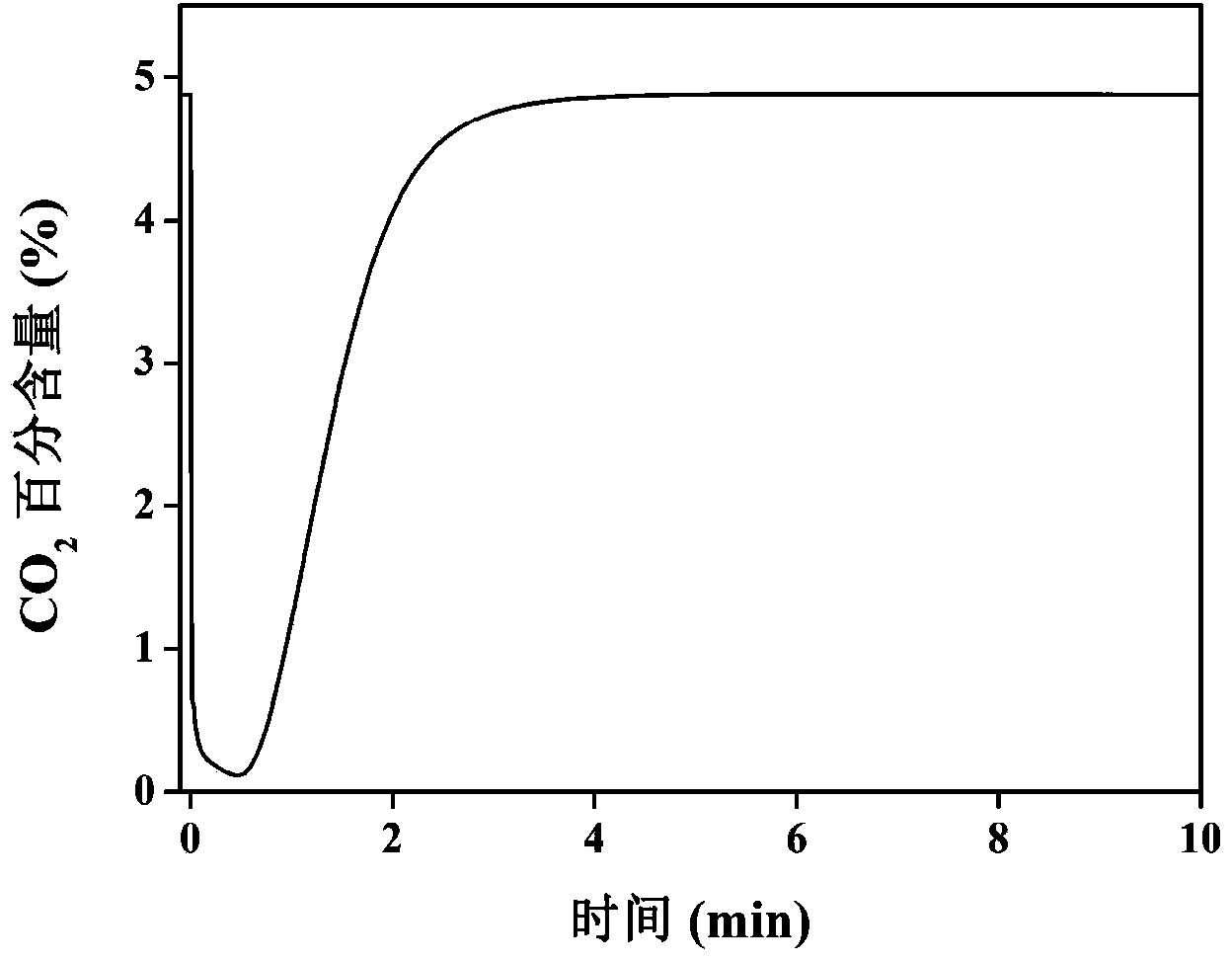

Image

Examples

preparation example 1

[0030] a. Add 0.81g Bi(NO 3 ) 3 Dissolve in a mixed solution of 50ml absolute ethanol and 20ml ethylene glycol, stir and dissolve to form solution A;

[0031] b. Add 1.05g H 3 Dissolve BTC in 30ml of absolute ethanol, stir and dissolve to form solution B;

[0032] c. At room temperature, add solution B to solution A dropwise, stir, and mix solution A and solution B uniformly to obtain a mixed solution of solution A and solution B;

[0033] d. At 120°C, the mixed solution of solution A and solution B was crystallized for 2 days to obtain a solid product;

[0034] e. The solid product obtained in step d was washed with anhydrous methanol, and then the solid product washed with anhydrous ethanol was placed in a 120° C. drying oven for 12 h to obtain the metal-organic framework material Bi-BTC.

preparation example 2

[0036] a. 2.43g Bi(NO 3 ) 3 Dissolve in a mixed solution of 50ml absolute ethanol and 20ml ethylene glycol, stir and dissolve to form solution A;

[0037] b. Add 1.05g H 3 Dissolve BTC in 30ml of absolute ethanol, stir and dissolve to form solution B;

[0038] c. At room temperature, add solution B to solution A dropwise, stir, and mix solution A and solution B uniformly to obtain a mixed solution of solution A and solution B;

[0039] d. At 120°C, the mixed solution of solution A and solution B was crystallized for 3 days to obtain a solid product;

[0040] e. The solid product obtained in step d was washed with anhydrous methanol, and then the solid product washed with anhydrous ethanol was placed in a 120° C. drying oven for 12 h to obtain the metal-organic framework material Bi-BTC.

preparation example 3

[0042] a. 1.62g Bi(NO 3 ) 3 Dissolve in a mixed solution of 50ml ethanol and 30ml ethylene glycol, stir and dissolve to form solution A;

[0043] b. Add 1.05g H 3 Dissolve BTC in 30ml of absolute ethanol, stir and dissolve to form solution B;

[0044] c. At room temperature, add solution B to solution A dropwise, stir, and mix solution A and solution B uniformly to obtain a mixed solution of solution A and solution B;

[0045] d. At 130°C, the mixed solution of solution A and solution B was crystallized for 2 days to obtain a solid product;

[0046] e. Wash the solid product obtained in step d with absolute ethanol, and then place the solid product washed with absolute ethanol in a 120° C. drying oven for 12 hours to obtain the metal-organic framework material Bi-BTC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com