A Viscous Medium External Pressure Forming Method for Large Curvature Thin-walled Components

A technology of thin-walled components and viscous media, which is applied in the field of forming large-curvature thin-walled components. It can solve the problems of easy instability and wrinkling of formed parts, thinning of the wall thickness of formed parts, and poor forming accuracy, so as to avoid wall thickness reduction. and wrinkling, large diameter reduction, and strong strain rate sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

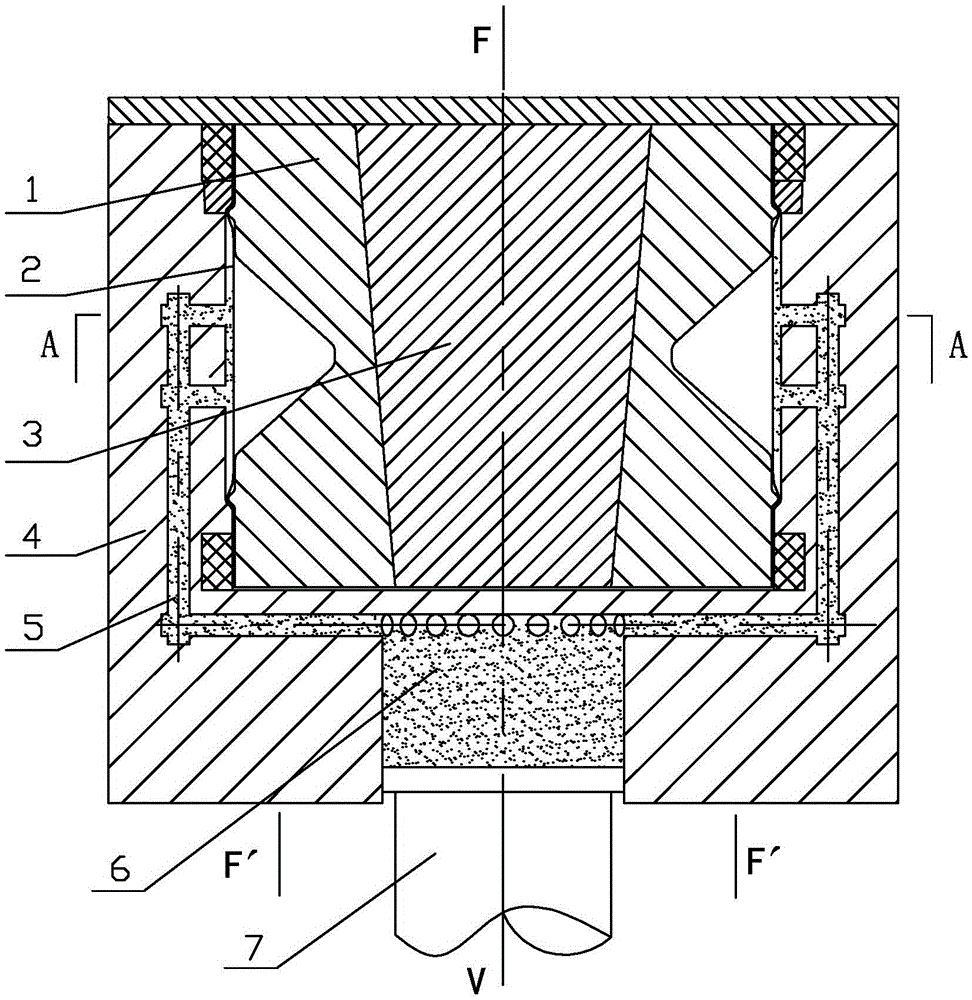

[0027] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this implementation mode, this implementation mode is realized through the following steps:

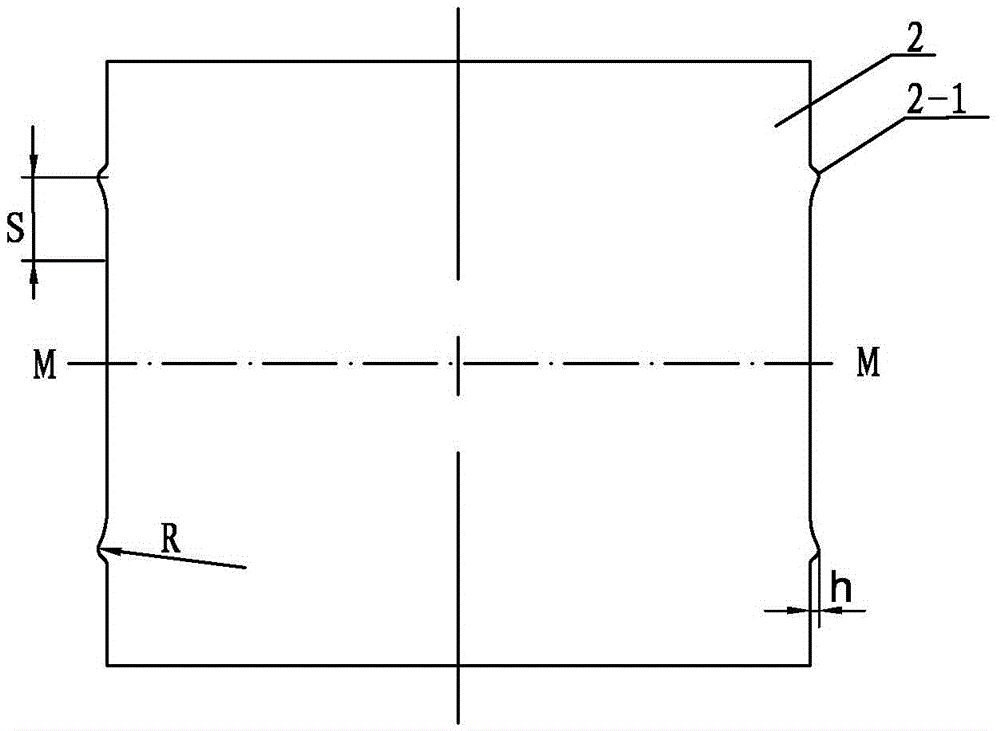

[0028] Step 1, making the tube blank 2: roll and weld the plate to form a cylinder, see figure 1 , the material flow control rib 2-1 is arranged symmetrically on the cylinder wall with the cylinder length center M-M as the reference, the distance s between the material flow control rib 2-1 and the entrance of the variable diameter area is 5 mm to 30 mm, see figure 2 ; The structural shapes of the material flow control ribs 2-1 at both ends of the billet 2 can be different. Through the resistance of the material flow control rib 2-1, the inflow of the material at the end is adjusted and controlled, so that the wall thickness of the formed part is less thinned and wrinkle-free.

[0029] Step 2, the tube blank 2 is loaded into the external pressure forming mold: the tube blank 2 is loaded into the core mo...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination figure 2 To describe this embodiment, the distance s between the material flow control rib 2 - 1 and the entrance of the variable diameter area in Step 1 of this embodiment is 20 mm. For general large-curvature external pressure parts, the forming quality is better, and for special formed parts, it is necessary to reasonably adjust and control the distance s between the ribs and the entrance of the mandrel. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific implementation mode three: combination Figure 1 to Figure 8 To illustrate this embodiment, the material of the tube blank 2 in step 1, step 2 and step 3 of this embodiment is stainless steel or superalloy. For external pressure forming of large curvature parts, if control ribs are not used, the diameter reduction is small, and it is difficult to form large curvature parts. However, if the control ribs are used for forming, the diameter reduction is large, and larger curvature parts can be formed. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com