Diameter reducing device and method for non-uniform-thickness rubber ball joints

A rubber ball hinge, non-equal thickness technology, applied in the field of diameter reduction of thick rubber ball hinges, can solve the problems of diameter deviation, limited one-time diameter reduction, space and real size deviation, etc., to reduce the diameter reduction. difference, improve the reliability of reducing diameter, and improve the effect of cylindricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

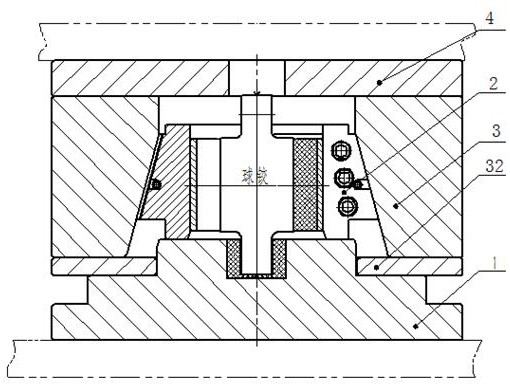

[0037] Combine below Figure 3 to Figure 8 Embodiments of the present invention are described in detail.

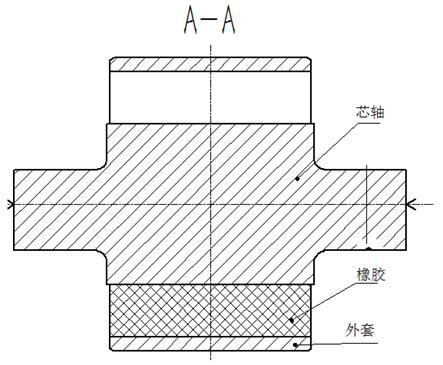

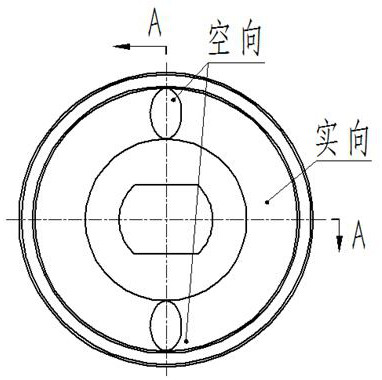

[0038] Non-equal-thickness rubber ball joint diameter reducing device, including a base 1 supporting the ball joint vertically, a chuck valve mold assembly 2 placed on the base and capable of surrounding the ball joint in a circumferential direction, and used for aligning the chuck valve mold assembly 2 The middle mold 3 that applies radial pressure and the upper module 4 used to drive the middle mold 3 up and down, the middle mold 3 is set on the chuck valve mold assembly 2 and cooperates with the cone surface of the chuck valve mold assembly 2, the chuck The valve mold assembly 2 radially compresses the spherical hinge as the middle mold 3 descends, and the chuck valve mold assembly 2 is formed by sequentially splicing a plurality of valve molds along the circumferential direction, and is characterized in that the valve molds are divided into pairs of spherical The hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com