Punching integral machine tool

A punching and integrated technology, which is applied in the field of mechanical processing, can solve the problems of affecting the processing accuracy of workpieces, high labor intensity of workers, and manual error of hole spacing, so as to improve processing efficiency, reduce labor intensity of workers, and ensure synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

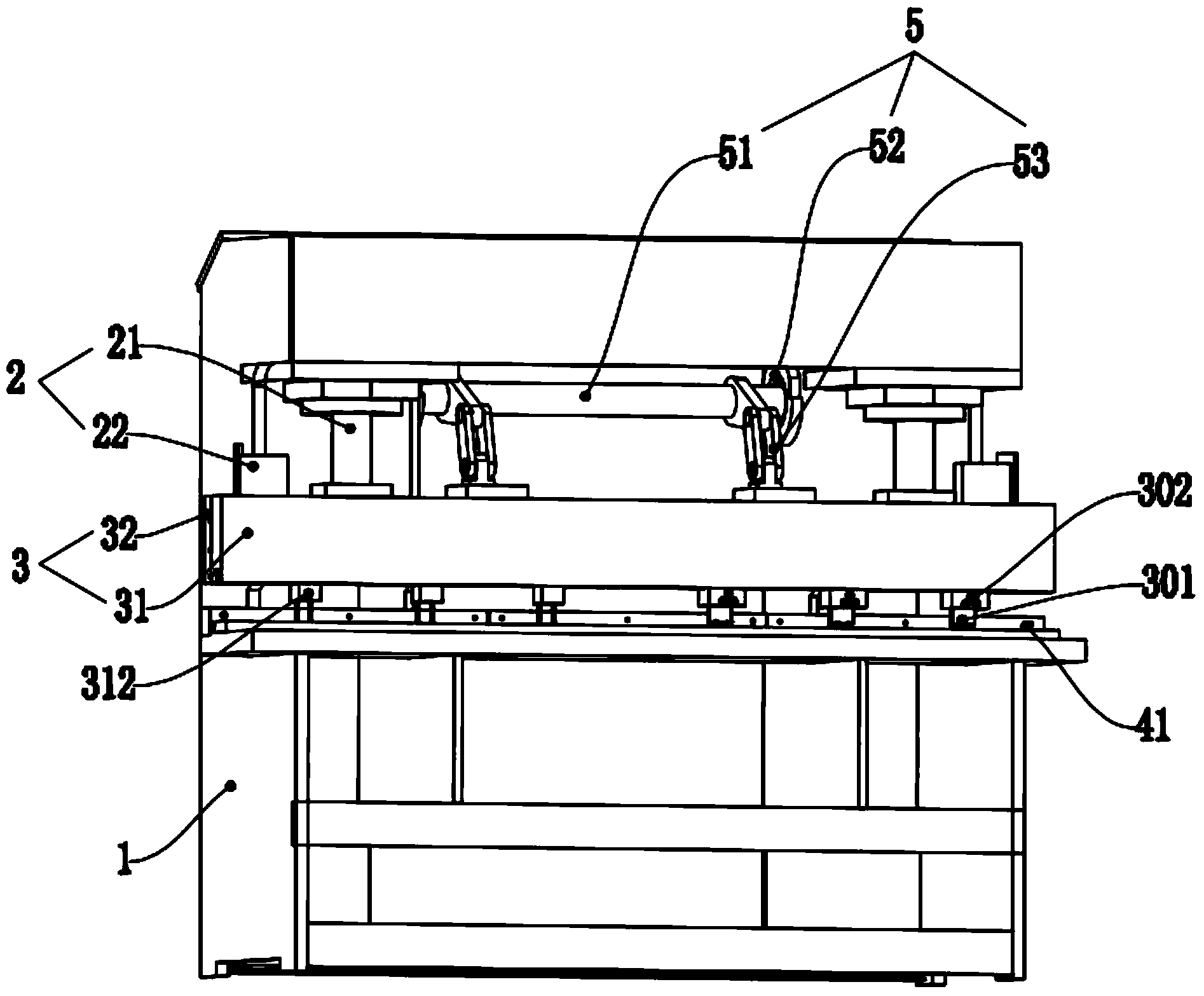

[0026] An integrated punching machine tool, comprising a frame 1, a power mechanism 2, a punching mechanism 3, a limit mechanism 4 and a rigid synchronization mechanism 5;

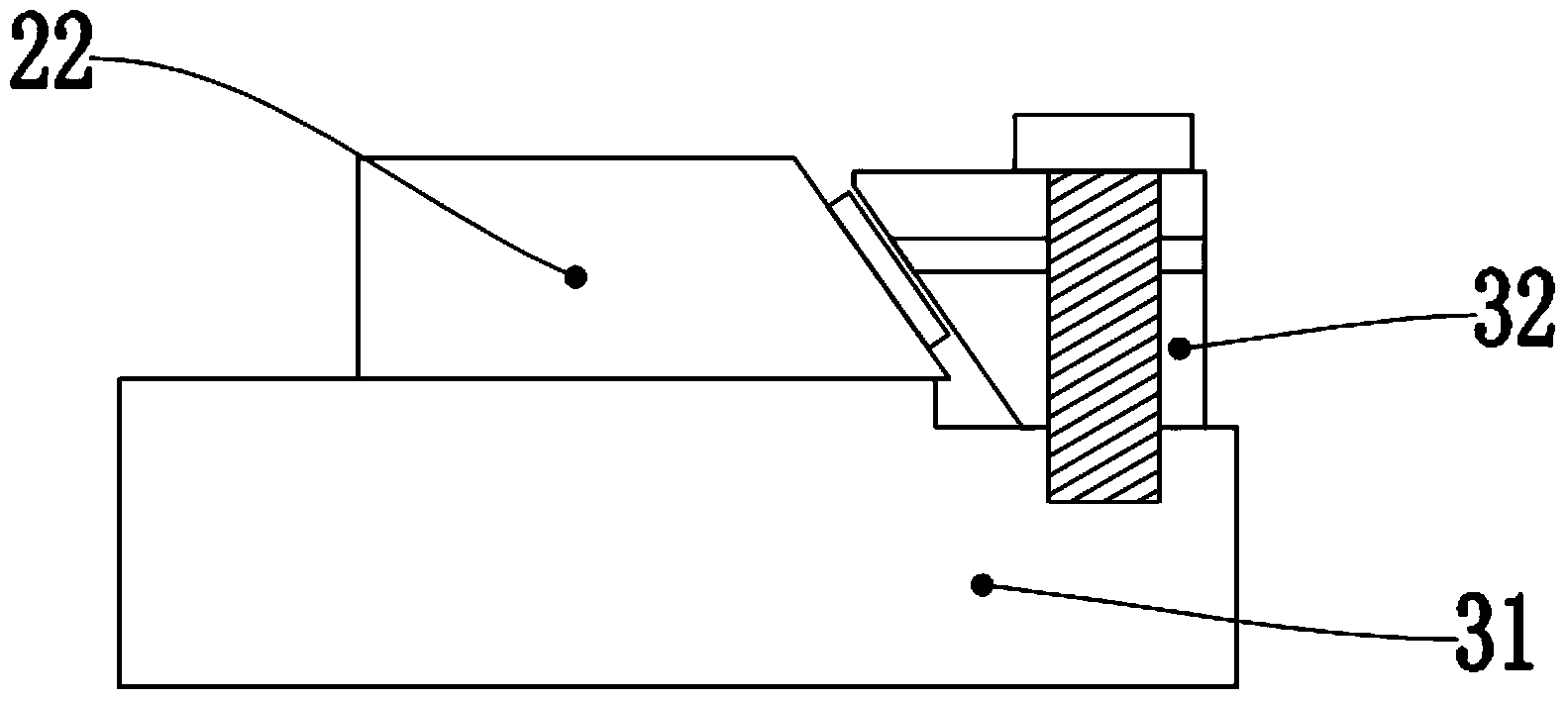

[0027] The power mechanism 2 includes a hydraulic cylinder 21 for moving up and down, and the hydraulic cylinder 21 is arranged above the frame 1;

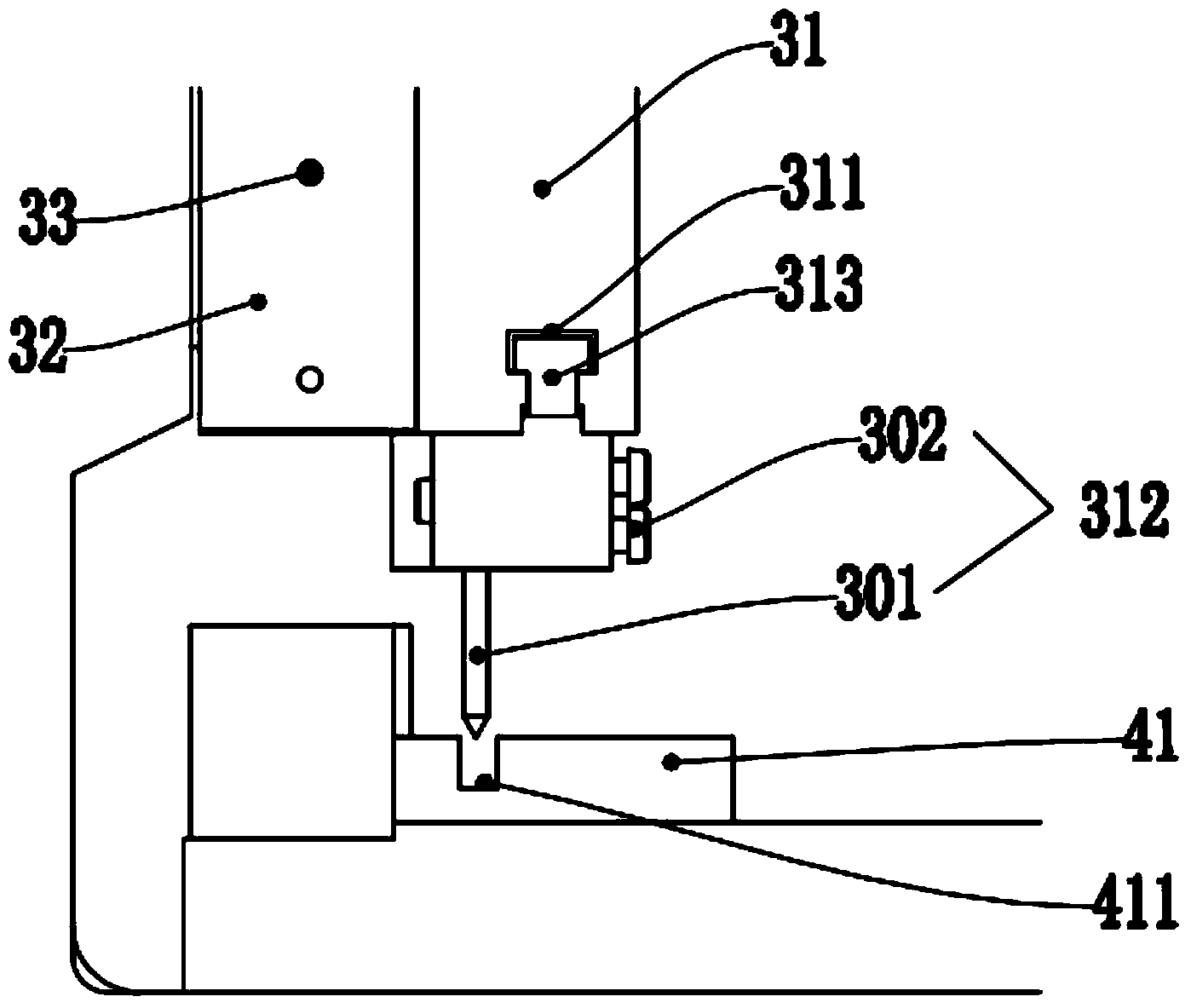

[0028] The punching mechanism 3 includes an upper die cutter plate 31 provided with a plurality of cutters 312, the two ends of the upper die cutter plate 31 are respectively connected to the movable rod of the hydraulic cylinder 21 and driven up and down by the hydraulic cylinder 21. The movement realizes punching, and the number and interval of the knives 312 of the upper die cutter plate 31 are set according to the number and interval of punching required by the workpiece;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com