High-speed semi-solid pulping machine

A semi-solid slurry and semi-solid technology, applied in the field of metal forming, to reduce energy consumption, improve stability and reduce temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

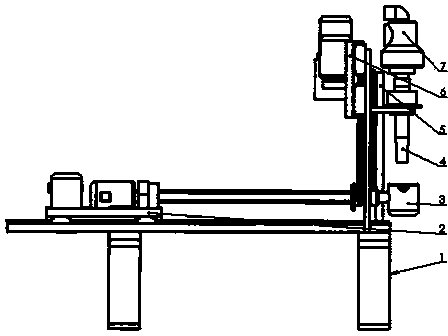

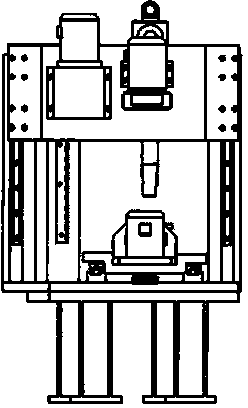

[0015] The high-speed semi-solid pulping machine is composed of a frame, a base, a pulping cylinder, a turning mechanism, a stirring device, a temperature control system, a monitoring system and a servo system. The side of the pulping cylinder is fixed on the end of the telescopic rod of the turning mechanism, and the stirring device is above the pulping cylinder. When the liquid metal is injected into the pulping cylinder by the soup feeder, the stirring device is lowered, and the stirring rod is inserted into the pulping cylinder to start stirring. The temperature control system starts for pulping. After the pulping is completed, the stirring device rises back to the position, the motor drives the telescopic rod to move the pulping cylinder to the feed port of the molding machine, the turning mechanism turns over, drives the pulping cylinder to send the slurry into the molding machine barrel, and the molding machine completes the molding process .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com