Six-degree-of-freedom positioning gesture adjusting equipment used for automatic assembling of large barrel-shaped thin-wall construction member

A technology of thin-walled components and automatic assembly, which is applied in the field of devices in the field of assembly and docking technology. It can solve the problems of limited response speed and precision, complex control methods, and increased costs, and achieve fast response speed, high operation accuracy, and large range of motion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

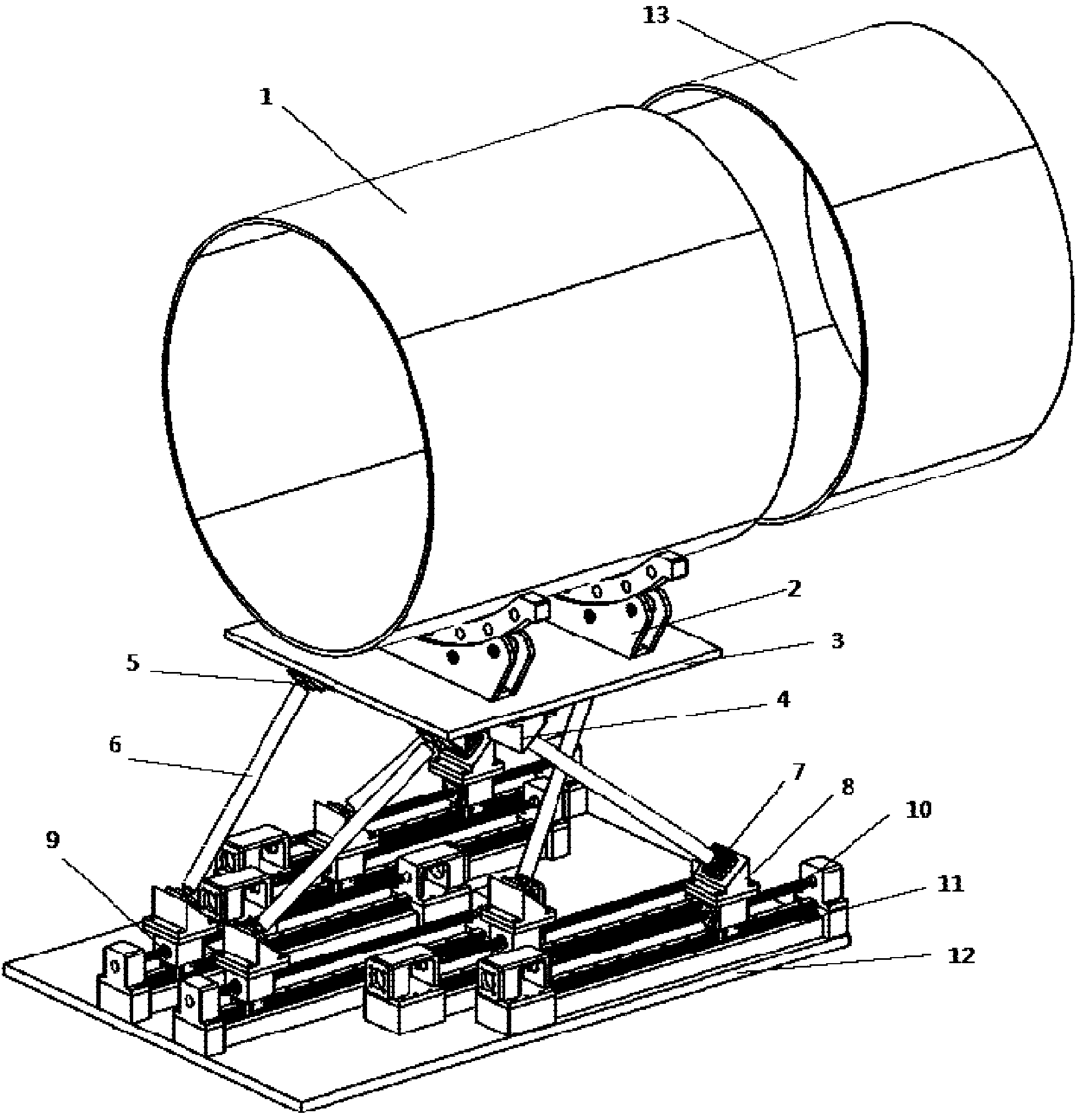

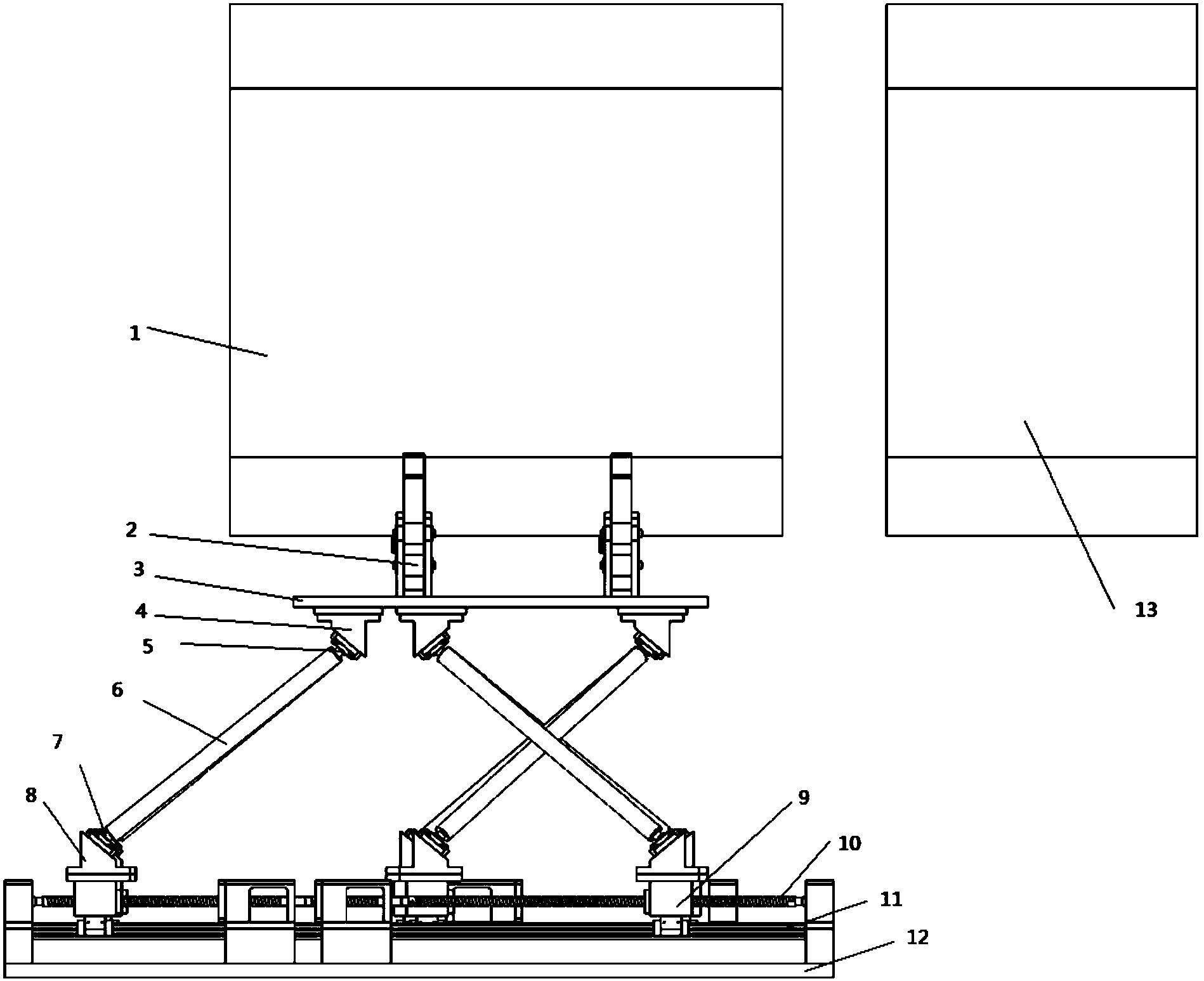

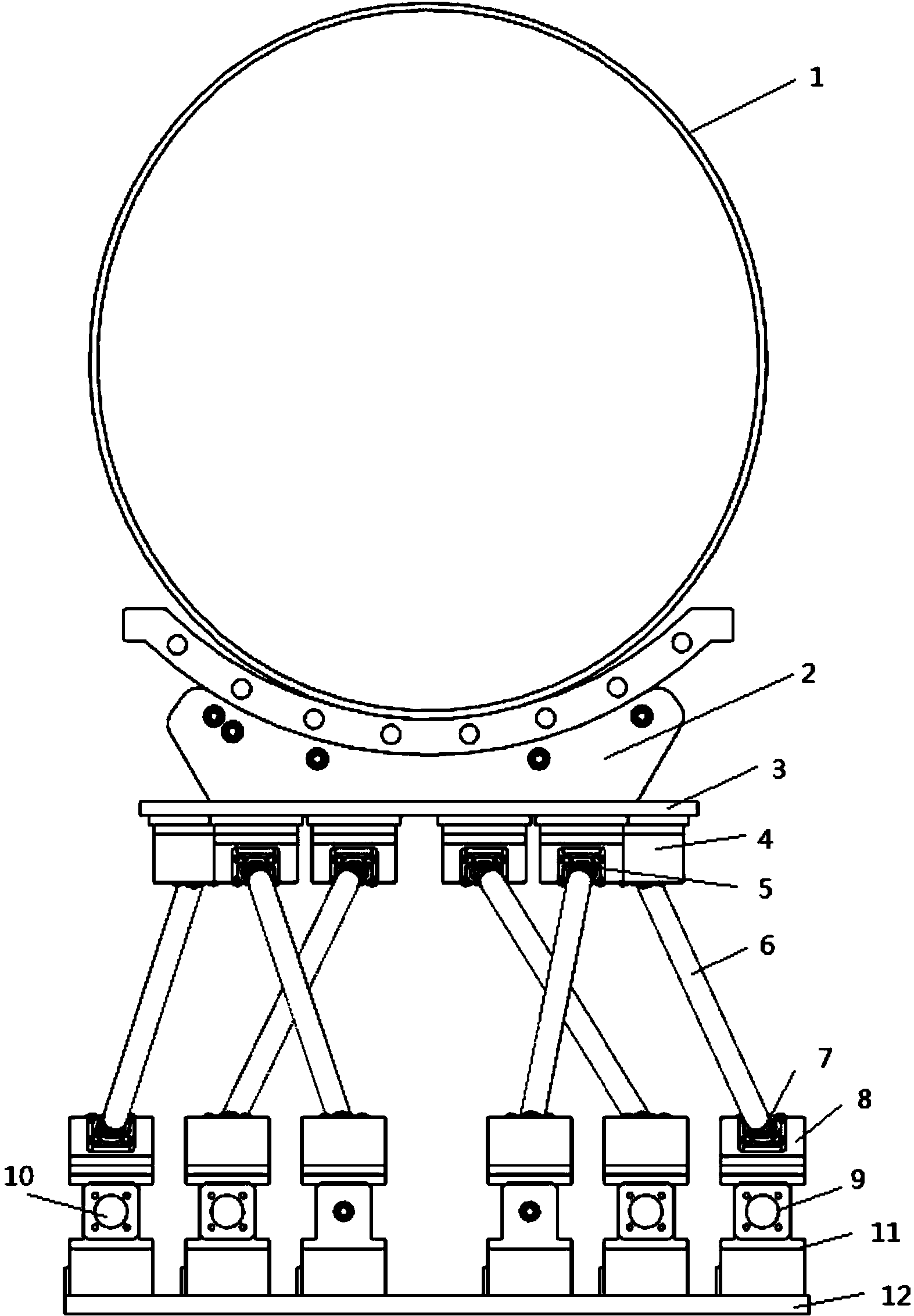

[0027] Such as Figure 1 to Figure 3 As shown, this embodiment includes: an adjustment platform 3 with a component bracket 2, a floor platform 12 and six PSS branch chains respectively connected thereto, wherein: a cylindrical thin-walled component 1 and a C-shaped bracket 2 The component bracket 2 is aligned and flat on the moving platform 3 through the arc surface contact connection.

[0028] The adjusting and moving platform 3 adopts a flattened steel plate, which is used to support the component bracket 2 and the thin-walled component 1 .

[0029] In this embodiment, the layout of the six PSS branches is as follows Figure 1 to Figure 3 As shown, the structure of the six PSS branch chains is basically the same except that the length of the support rod is customized according to specific requirements.

[0030] Such as Figure 4 , 5 As shown, the PSS branch chain includes: a support rod 6, ball hinges 5 and 7, ball joint auxiliary bearing seats 4 and 8, nut support 9, sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com