Automatic turnover machine

A technology of automatic turning and equipment, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of lack of flexible buffer mechanism, inappropriate installation space, and large installation space, so as to reduce production costs, reduce layout space, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

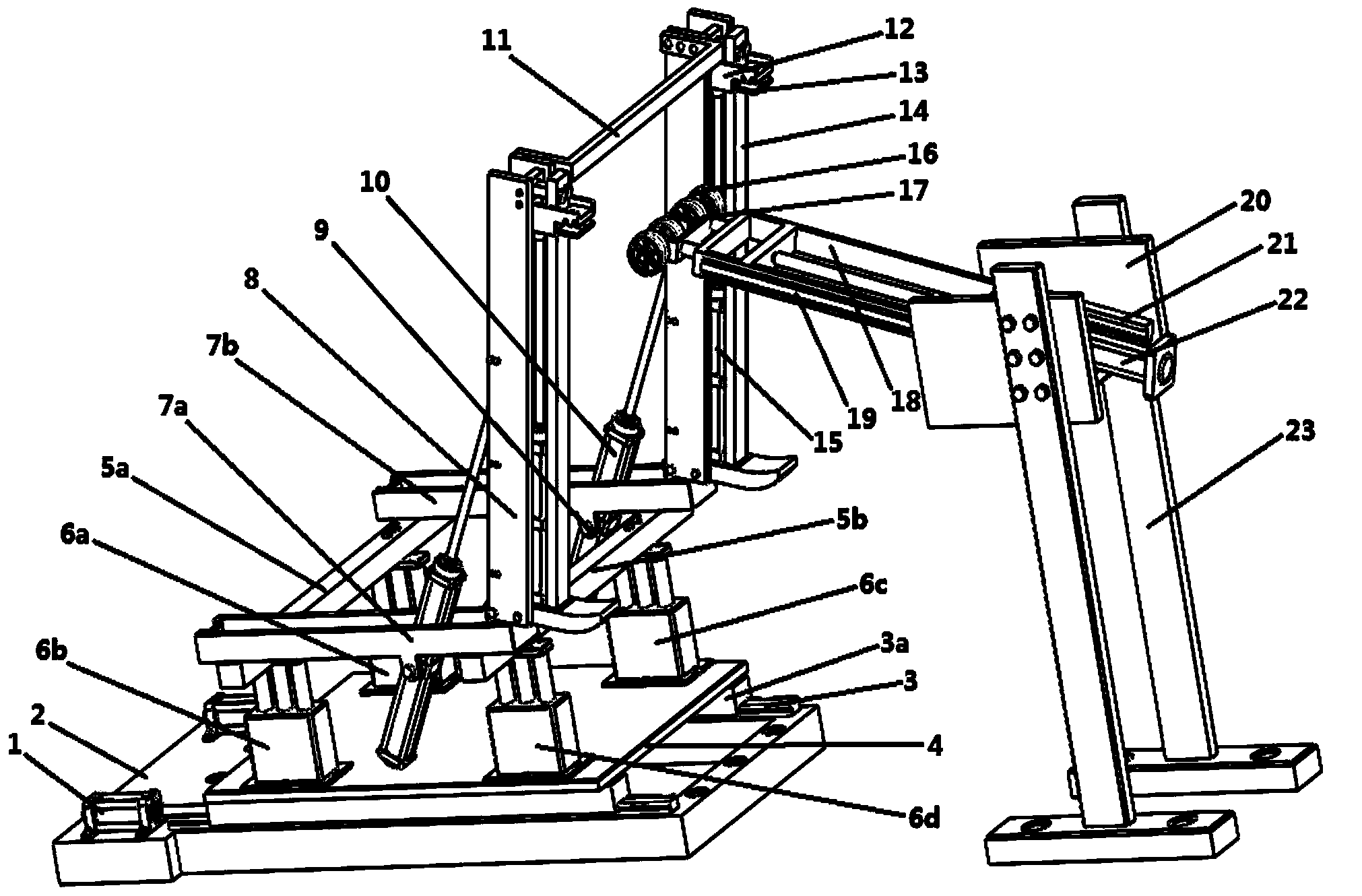

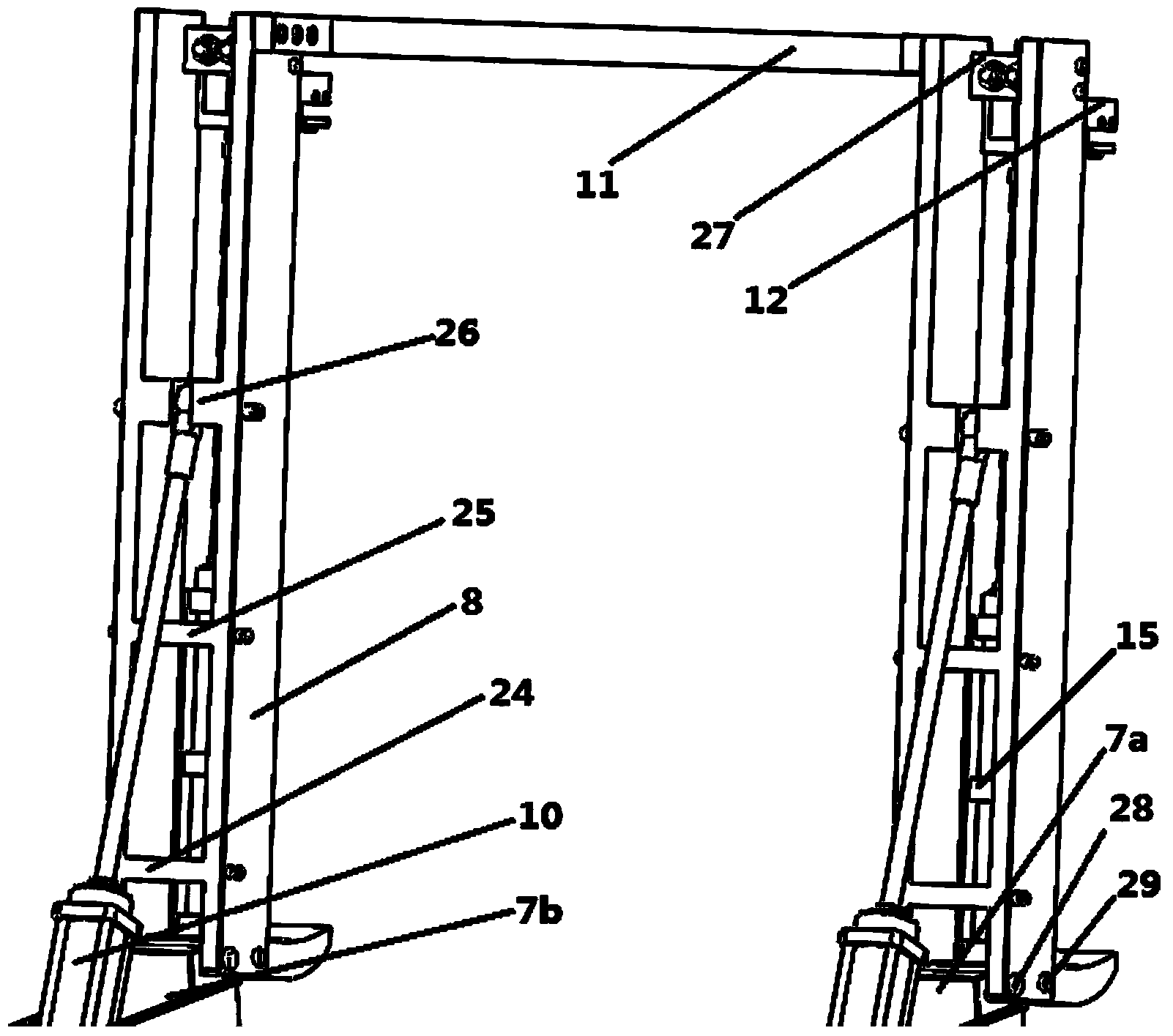

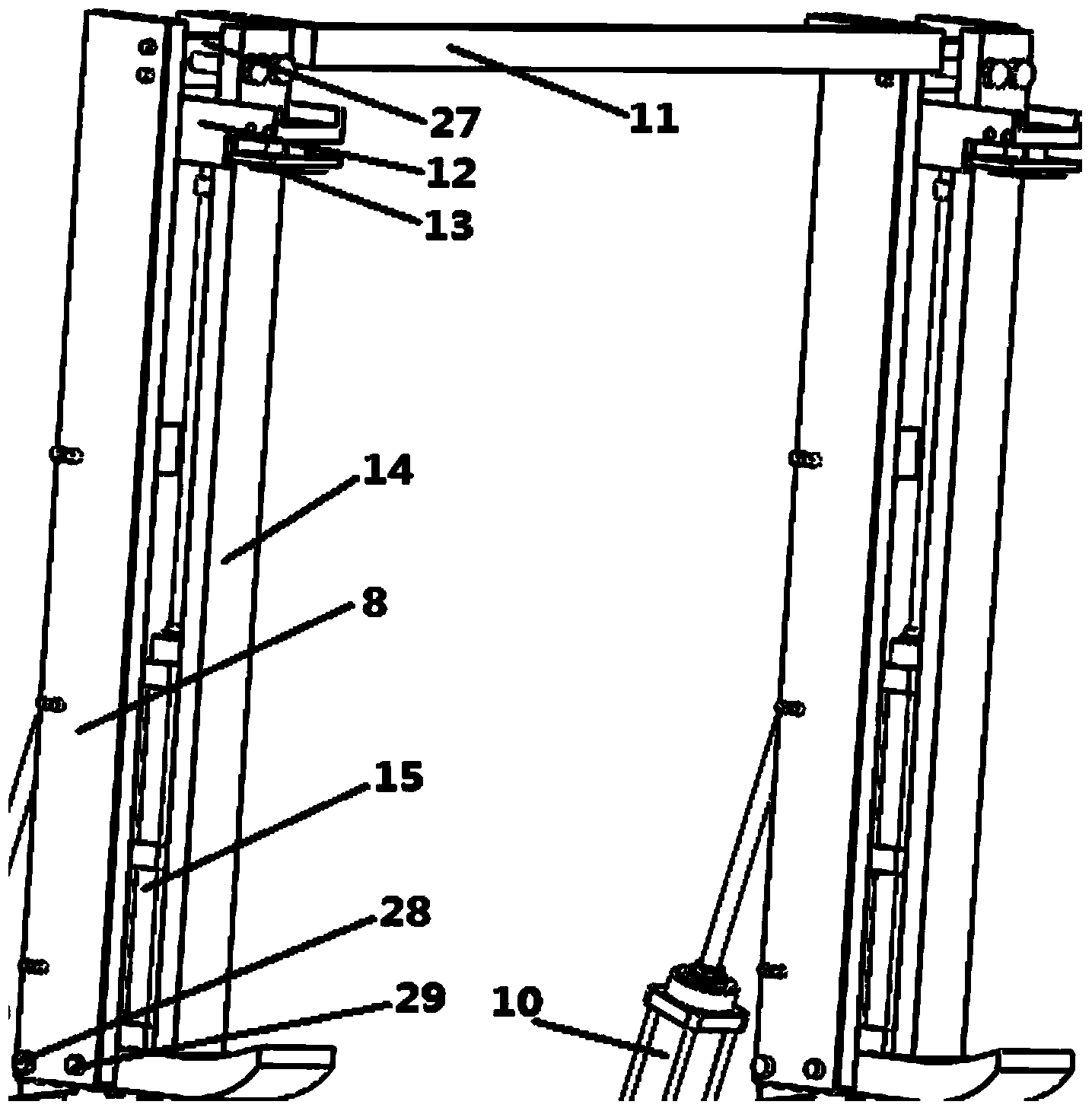

[0033] see figure 1 , an automatic overturning device, which is used to overturn a workpiece from a horizontal state to an upright state, and its composition includes: a transverse feeding mechanism, a longitudinal lifting mechanism, a lateral turning mechanism, a clamping mechanism and a supporting mechanism;

[0034] The composition of the transverse feed mechanism includes a linear cylinder 1, a first guide rail 3, a first guide rail seat 3a, a flat support 4 and a base 2;

[0035] Symmetrical first guide rails 3 are arranged on both sides of the base 2, and a first guide rail seat 3a matching the first guide rail is provided on the first guide rail 3 for supporting the flat panel support 4; that is, the first guide rail seat is welded to the flat panel support 4; at the end position of the first guide rail 3, a direct-acting cylinder 1 connected with the first guide rail seat 3a is arranged on the base 2; that is, the cylinder rod of the direct-acting cylinder 1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com