Ground wire automatic winding device

A technology of automatic winding and grounding wire, applied in the field of automatic grounding wire winding device, can solve the problems of unequal gap between wires, not easy to wind, and affect the appearance, so as to reduce operation and maintenance costs, save production costs, and increase safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

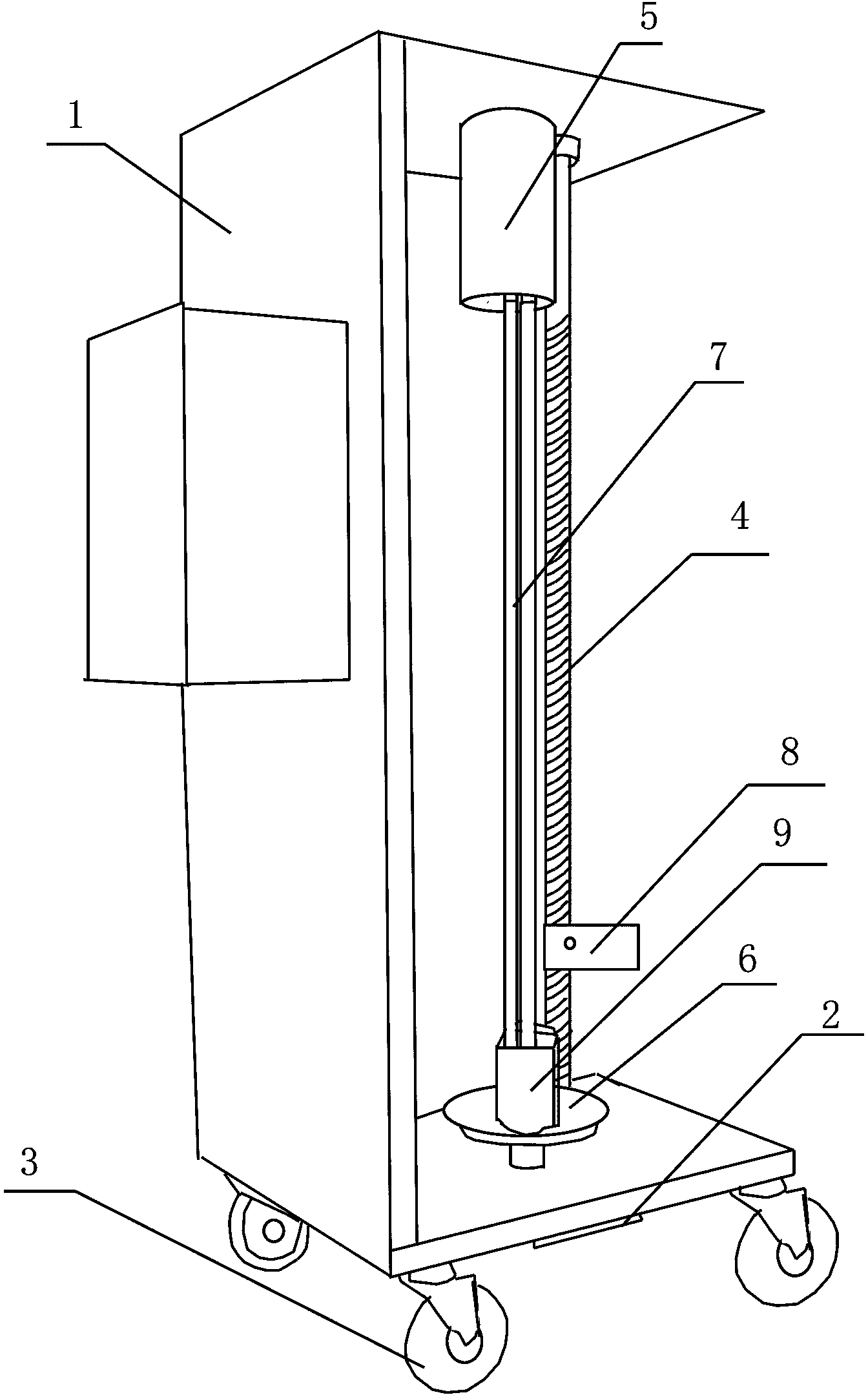

[0008] exist figure 1 Among them, the present invention provides a grounding wire automatic winding device, which is provided with a casing 1 and a motor 2, the casing 1 is a semi-open casing, the open casing 1 is set as a cuboid casing, and the open casing The two adjacent sides are set as openings, and the rest of the open casing is provided with a baffle, and the bottom of the semi-open casing is provided with a wheel 3, and the wheel 3 provided at the bottom of the semi-open casing 1 is a universal wheel. The inner cavity of the semi-open shell is provided with a ground rod installation device and a winding rod 4. The ground rod installation device includes a positioning cylinder 5 and a rotating disk 6 for the ground rod 7, and the positioning cylinder 5 of the ground rod 7 is installed on the shell 1, the rotating disk 6 is located at the bottom of the inner cavity of the housing 1, the rotating shaft in the rotating disk 6 is connected to the output end of the motor 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com