Polybutylene adipate-co-terephthalate compound materials and preparation method thereof

A technology of butylene terephthalate and polyadipic acid, which is applied in the field of preparation of polymer composite materials, can solve the problem of large phase domains of blended materials, expensive block copolymers, and the decline in comprehensive performance and pure polymers and other issues to achieve the effect of improving strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

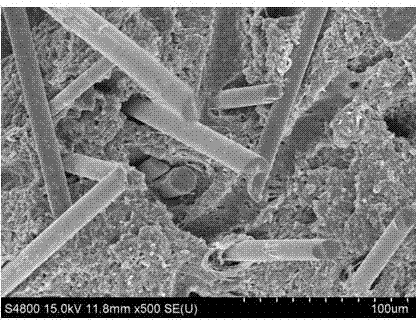

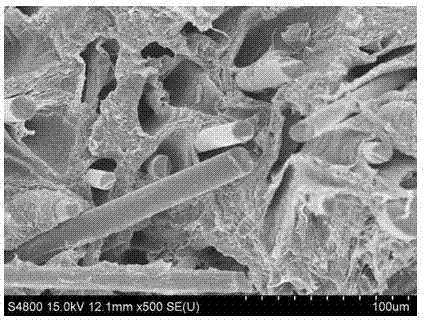

[0020] 1. Mix the dried polybutylene adipate-terephthalate and polylactic acid at a mass ratio of 70:30 and place them in a Haake torque rheometer, and control the rotor shear rate to 50 at a temperature of 180°C. the s -1 ~100s -1 , melt blended for 2 min, then added 15% of the total mass of glass fibers and blended for 6 min before discharging.

[0021] 2. Use a micro-injection molding machine to inject the output into standard dumbbell-shaped (32 mm×4 mm×2 mm) and standard rectangular (80 mm×10 mm×4 mm) specimens for testing tensile and impact properties. The injection process is as follows: barrel temperature 180°C, mold temperature 30°C, injection pressure 600 bar, holding pressure 500 bar.

Embodiment 2

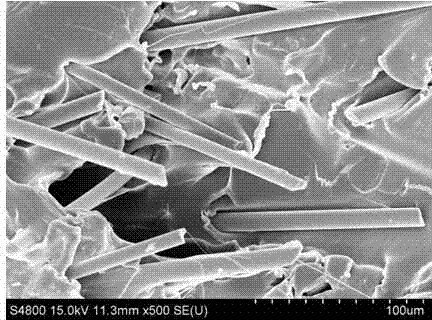

[0023] 1. Mix the dried polybutylene adipate-terephthalate and polylactic acid at a mass ratio of 70:30 and place them in a Haake torque rheometer, and control the rotor shear rate to 50 at a temperature of 180°C. the s -1 ~100s -1 , melt blended for 2 min, then added glass fibers accounting for 20% of the total mass and blended for 6 min before discharging.

[0024] 2. Use a micro-injection molding machine to inject the output into standard dumbbell-shaped (32 mm×4 mm×2 mm) and standard rectangular (80 mm×10 mm×4 mm) specimens for testing tensile and impact properties. The injection process is as follows: barrel temperature 180°C, mold temperature 30°C, injection pressure 600 bar, holding pressure 500 bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com