Silicone sealant and preparation method thereof

A technology of silicone sealant and hydroxyl sealant, which is applied in the direction of chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of unsatisfactory concrete bonding performance and low modulus of silicone sealant, so as to avoid oil seepage Phenomenon, good weather aging resistance, excellent adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides the preparation method of above-mentioned silicone sealant, comprises the following steps:

[0028] a. Dehydrate 100 parts of hydroxyl-terminated polydimethylsiloxane, 1 to 5 parts of fumed white carbon black and 1 to 150 parts of nanometer calcium carbonate for 1 to 4 hours, and cool to room temperature to obtain the base material;

[0029] b. Then add 1-12 parts of coupling agent, 0.1-4 parts of tackifier, 8-60 parts of plasticizer, 0.1-1.8 parts of anti-fungal agent and 0.1-5 parts of catalyst, and the vacuum degree is 0.075-0.095MPa Stirring at low temperature for 0.5-2 hours to obtain silicone sealant.

[0030] Wherein, in the step a of the preparation method of the above-mentioned silicone sealant, the temperature of the dehydration is 90-140° C., and the degree of vacuum is 0.075-0.095 MPa.

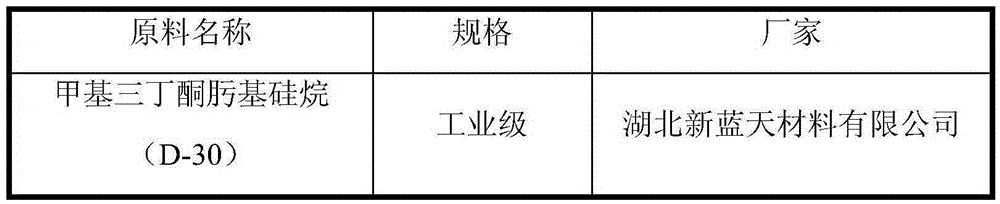

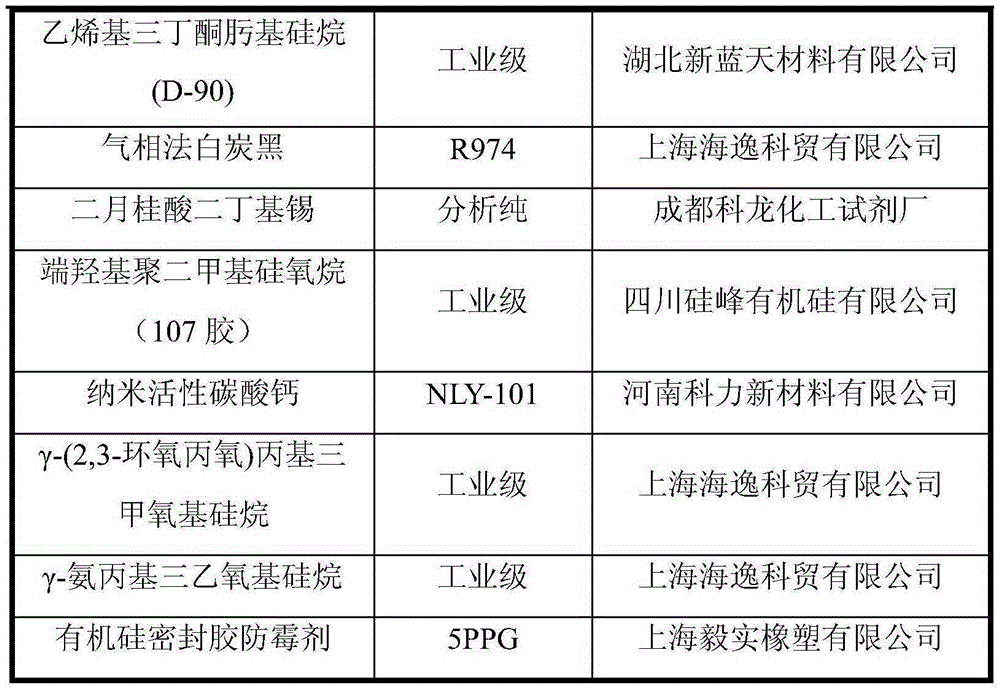

[0031] The sources and specifications of the raw materials used in the embodiments of the present invention are shown in Table 1:

[00...

Embodiment 1

[0036] Add 300 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 50 Pa.s at 25°C, 210 parts of nano-active calcium carbonate, and 12 parts of fumed white carbon black into a power mixer, at 135°C, vacuum The density is 0.075-0.095MPa, dehydration and blending for 1 hour, and cooling to room temperature to obtain the base material. At room temperature, mix 25 parts of methyl tributyl ketoxime silane, 65 parts of long-chain liquid silicone resin, 7.5 parts of γ-aminopropyl triethoxysilane, 4 parts of silicone sealant antifungal agent, dilauric acid di 3 parts of butyl tin, stirred for 1 hour under the vacuum condition of 0.075-0.095MPa, and filled with air isolation, to obtain the silicone sealant product.

Embodiment 2

[0038] Add 300 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 80 Pa.s at 25°C, 150 parts of nano-active calcium carbonate, and 15 parts of fumed white carbon black into a power mixer, at 120°C, vacuum The density is 0.075-0.095 MPa, dehydrated and blended for 1.5 hours, cooled to room temperature to obtain the base material. At room temperature, mix 21 parts of vinyl tributyl ketoxime silane, 70 parts of long-chain liquid silicone resin, 7.5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, and silicone sealant to prevent mildew 5 parts of tin octoate, 5 parts of stannous octoate, stirred for 1 hour under vacuum conditions, and filled with air isolation, to obtain the silicone sealant product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com