One-spray-six-weft-yarn high-count high-density large-width fabric and production method

A technology of wide fabric and production method, applied in the field of spinning and weaving, can solve the problems of high warp density, great difficulty in weaving, and small number of doubling yarns, so as to achieve soft and comfortable hand feel, reduce weaving slip back, and reduce weft insertion. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

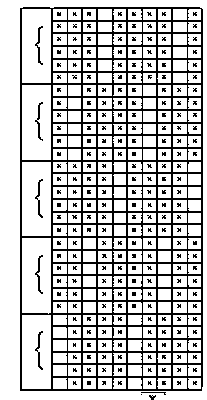

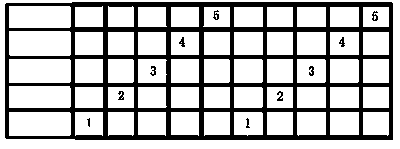

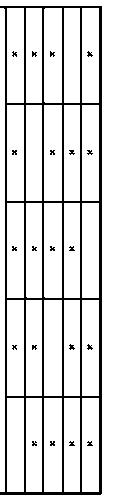

[0037] The present invention uses the ZAX-340 Japan Tsudakoma air-jet loom, adopts long-staple cotton with a maturity of not less than 1.7, a main body length of 37mm, a micronaire value of 3.7, and a fineness difference close to that of raw cotton within 2.5 dtex, and the warp yarn is combed Pure cotton 7.3tex yarn, combed pure cotton 7.3tex yarn is used as the weft yarn, the fabric weave is five pieces of three-flying satin weave, and six jet wefts. After opening and cleaning, carding, combing, drawing, roving, spun yarn, winding, twisting, and stranding, 7.3tex single yarn and 7.3tex / 6 strands are produced, and then warping, sizing, and weaving process to produce multi-jet weft fine extra-high-density wide-width fabrics.

[0038] The specific process steps of a spray of six weft yarns of the present invention are as follows.

[0039] 1. The specific steps of the spinning production process.

[0040] (1) Start cleaning process

[0041] This process adopts domestic cotton ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com