Hydraulic excavator movable arm priority hydraulic oil way and system vibration damping hydraulic loop

A hydraulic oil circuit and system vibration reduction technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of large hydraulic impact of stick hydraulic cylinders and uncoordinated compound actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

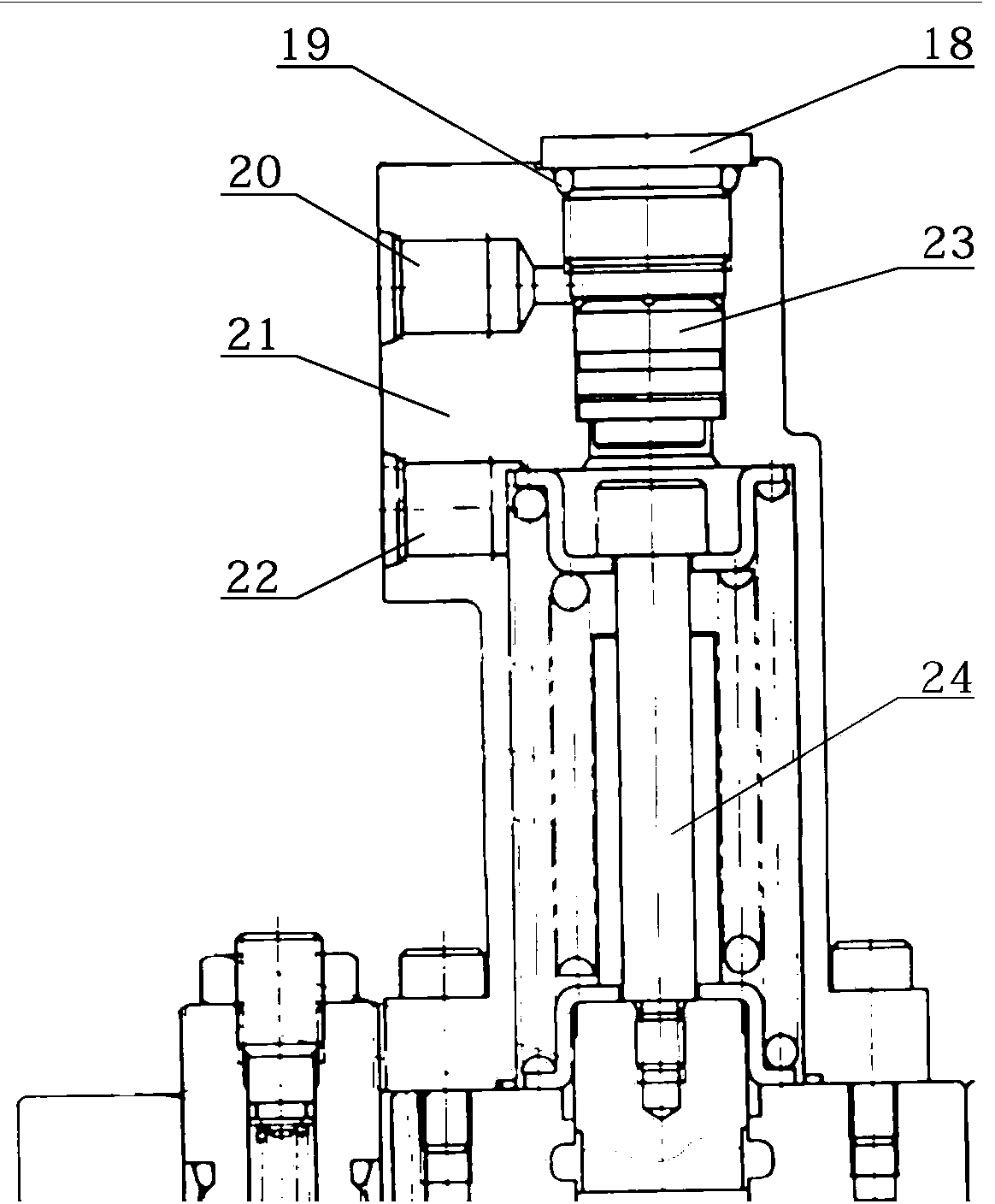

[0029] Such as figure 2 The structural layout diagram of the limit valve 5 and the bucket control valve 4 shown, the spring cover 21 has a boom priority servo port 21 and a bucket servo port 22, and the boom priority servo port 21 is connected to the boom large cavity (rodless Cavity) connected to the servo control port. When oil is fed into the large cavity servo control port of the boom and the priority servo port 21 of the boom at the same time, the servo pressure at the priority servo port 21 of the boom pushes the limit piston 23 in the limit valve 5 to move downward, and the bucket control valve 4 The bucket operating spool 24 inside moves upwards to contact the limit piston 23, and the pressure above the limit piston 23 slows down the displacement speed of the bucket control spool 24, so that the oil flow into the bucket hydraulic cylinder 15 decreases and is distributed to the dynamic The oil flow rate of the large chamber of the arm hydraulic cylinder 16 is increase...

Embodiment 2

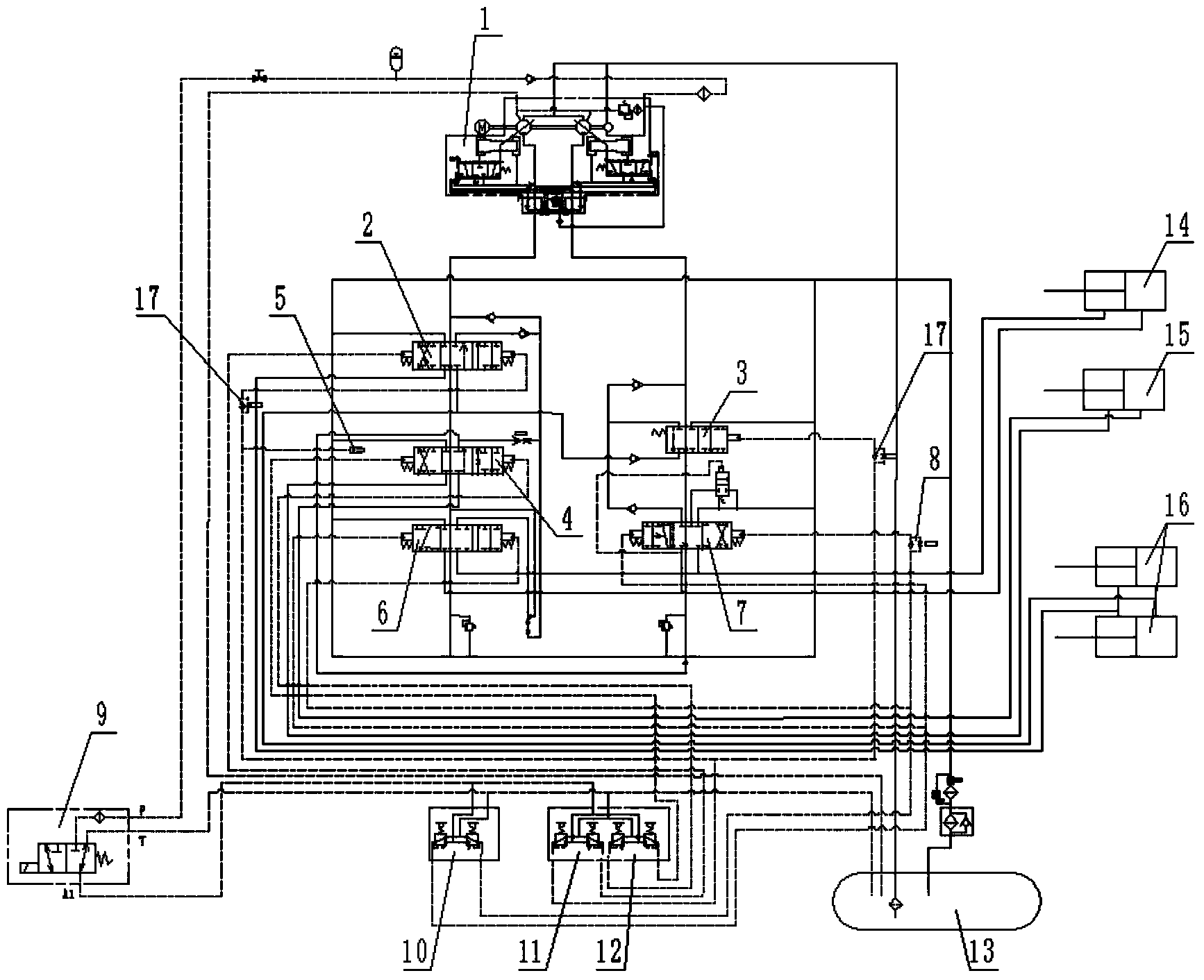

[0031] The excavator performs compound actions, operating the boom pilot operation valve 11 and the bucket pilot operation valve 12, the boom is in the lifting state, the bucket is in the digging state, the pilot part: the pilot servo pump on the pump body 1 supplies oil, and the servo pressure oil pushes The bucket control valve 4 is in the right position, and the bucket is in the digging state; the servo pressure oil simultaneously pushes the boom control valve 2 and the boom confluence valve 3 to the right position, and the boom is in the lifting state; and the servo pressure oil enters the limit valve 5 Finally, it acts on the spool of bucket control valve 4 (the left position of bucket control valve 4). Since the cross-sectional area of the limit piston is S1, the cross-sectional area of the valve core is S2, and S1<S2, so PS1<PS2, that is, the right position pressure PS2 is higher than left pressure PS1. The valve core opening degree of the bucket control valve 4 is ...

Embodiment 3

[0033] Operate the stick pilot operation valve 10 alone, the stick is in the lifting state, the pilot servo pump on the pump body 1 supplies oil, and the servo pressure oil first passes through the orifice with a diameter of φ=1.0mm in the one-way throttle valve A8, slowly Push the spools of the stick confluence valve 6 and the stick control valve 7, and open the one-way valve in the one-way throttle valve A8 after the pressure rises. The slow movement of the spools of the rod confluence valve 6 and the stick control valve 7 is in the right position. The small cavity of the stick hydraulic cylinder 14 slowly enters the oil, which plays a buffering effect and shortens the delay action time. When the stick pilot operation valve 10 is stopped, the small cavity of the stick hydraulic cylinder 14 stops feeding oil, the stick confluence valve 6 and the stick control valve 7 are about to be in the neutral position, and the one-way throttle valve A8 controls the return of servo oil S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The way to | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com