Corner marking device of electronic fuel injection engine

An engine and angle marker technology, which is used in engine ignition, electrical devices, engine components, etc., can solve the problems of high cost of crankshaft angle marker turntable, complicated angle marker signal calculation and processing, and complicated angle marker system, etc., and achieve high-precision cyclic phase. and crankshaft phase, low cost, and the effect of simplifying the angle marking device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

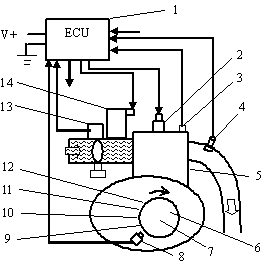

[0027] figure 1 It is a system diagram of an embodiment of the present invention on a motorcycle engine. The EFI engine is controlled by an electronic control unit (ECU) 1, and the input signals include signals from an engine temperature sensor 3, an oxygen sensor 4, a throttle position sensor 13, an angle sensor 8, and other sensor signals required to control the engine. The output signals include driving control signals for driving the fuel injector 14 and driving the ignition device 2 , and the like. The horn sensor 8 is fixedly installed on the engine body 5, and the magneto rotor 6 is installed on the engine crankshaft 7 and rotates synchronously with the engine crankshaft. The outer cylinder of the magneto rotor is made of magnetically permeable materials such as cast iron, ordinary steel plate, etc., and its shape includes two cylindrical surfaces (cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com