Cable type measurement system and measurement method for industrial robot spatial pose precision and track measurement

An industrial robot and measurement system technology, applied in the field of wire-drawn measurement systems, can solve the problems of high price, high environmental requirements, and low precision, and achieve the effects of long service life, large movement space, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

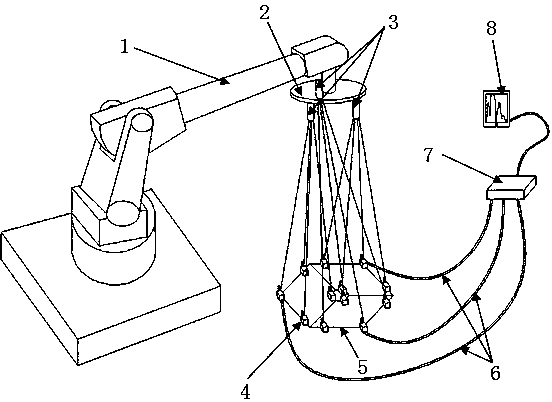

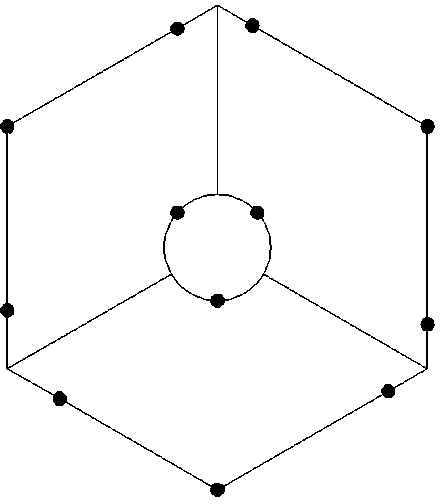

[0025] see figure 1 and figure 2 , a wire-drawn measurement system for spatial pose accuracy and trajectory measurement of industrial robots, including an industrial robot 1, a measurement assembly including a positioning disc 2, a measurement adapter 3, a wire-drawn encoder 4, a measuring rod 5, and a data line 6, A data acquisition card 7 and a computing terminal 8; the positioning disc 2 is coaxially installed on the end effector of the industrial robot 1 and can rotate freely, and three measuring adapters 3 are installed on the lower surface of the positioning disc 2, and the three measuring adapters The installation base points of 3 are not collinear; every four described wire-guide encoders 4 form a group, and each group of four wire-guy encoders 4 is respectively installed on the corresponding measuring rod 5, and the corresponding one is connected by four test cables. Measuring adapter 2, the base points of the twelve wire-drawing encoders 4 are in one plane, and the...

Embodiment 2

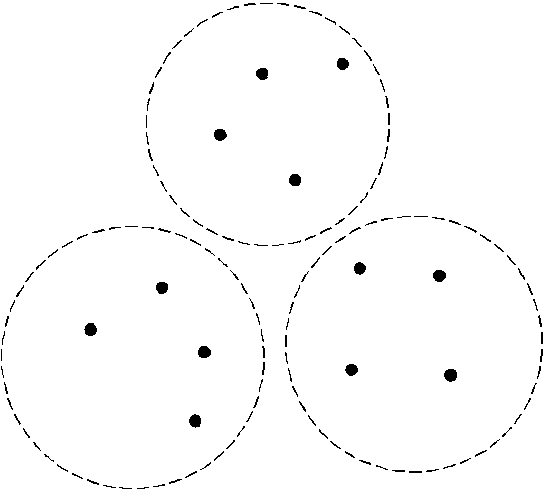

[0036] see image 3 , this embodiment is basically the same as Embodiment 1, the difference is that the measuring rod 5 is not used, and the twelve wire-guide encoders 4 are randomly placed, but it must be ensured that the base points of the twelve wire-guy encoders 4 are basically at one Plane and the center point where each group is located does not coincide with the other two groups. In each group, it must be ensured that the four points of the four wire-guide encoders 4 are not collinear. Repeat the measurement method of Example 1 to obtain the same result. It reflects the simplicity, reliability and low environmental requirements of the method, and is suitable for industrial field operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com